Key Manufacturing Process

1. Raw Material Extraction

- Mining: Titanium is extracted from ilmenite and rutile ores

- Beneficiation: Ores are processed to increase titanium dioxide content to 85-95%

- Chlorination: Ores react with chlorine gas at 900°C to produce titanium tetrachloride (TiCl₄)

2. Titanium Sponge Production

- Kroll Process: TiCl₄ is reduced with molten magnesium in argon atmosphere

- Temperature control: Reaction occurs at 1,100°C to prevent contamination

- Result: Porous titanium sponge with 99.5% purity

3. Alloy Creation and Melting

- Vacuum Arc Remelting (VAR): Sponge is compressed into electrodes and melted

- Alloy additions: Common alloys include Ti-6Al-4V (Grade 5)

- Ingot formation: Produces dense titanium ingots ready for processing

4. Forming and Shaping

- Hot working: Forging, rolling at 900-1100°C

- Cold working: Drawing, extrusion for precision components

- Heat treatment: Annealing at 650-760°C to enhance ductility

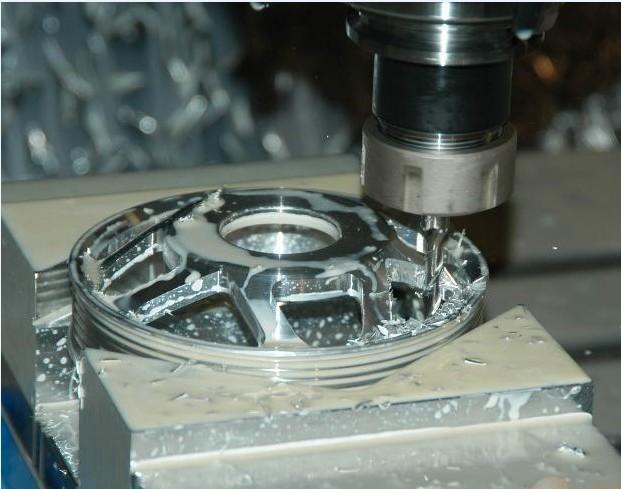

5. Machining and Finishing

- CNC machining: Precision cutting and shaping

- Surface treatment: Pickling, polishing, anodizing

- Quality testing: NDT, chemical analysis, mechanical testing

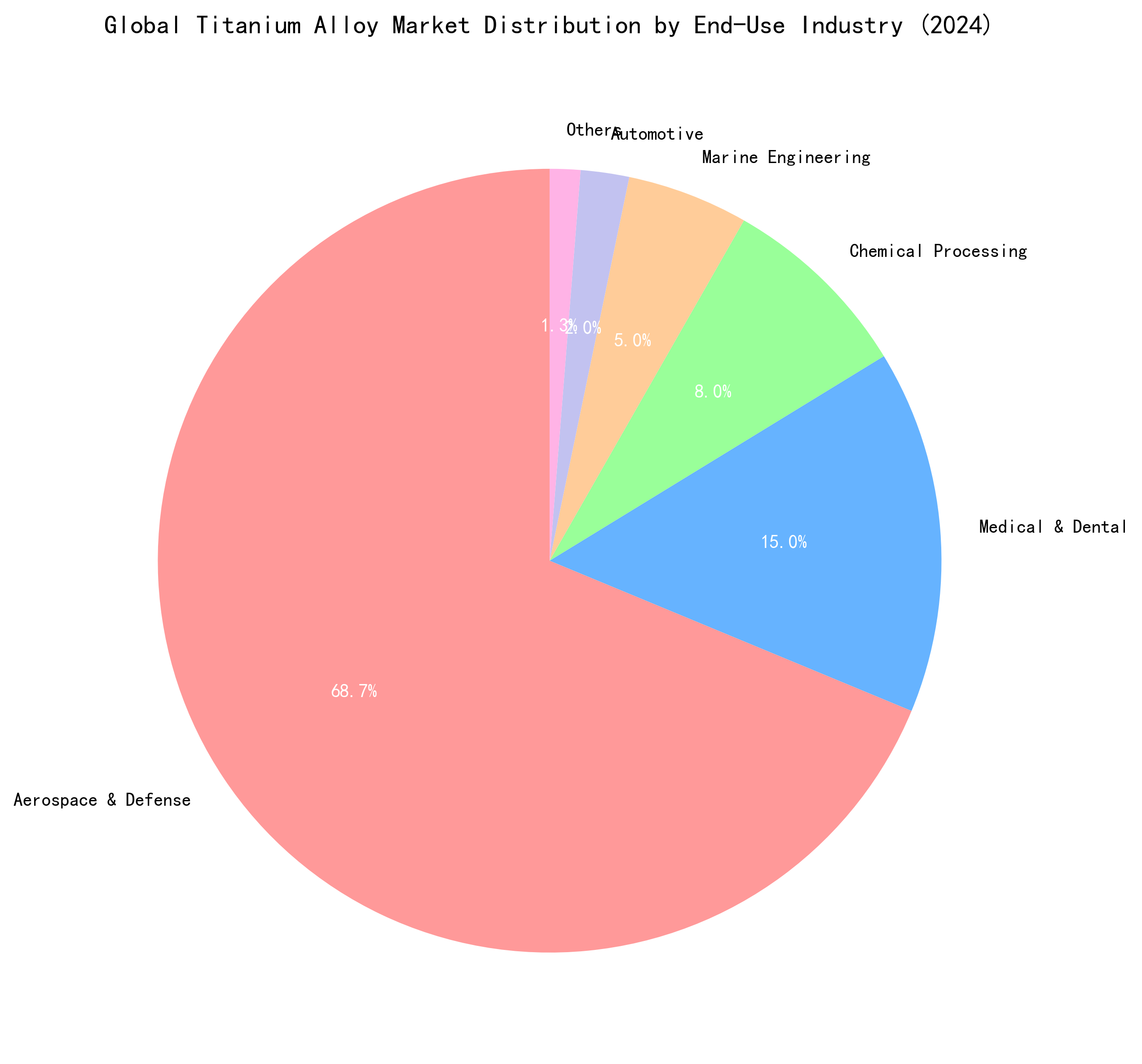

Market Distribution

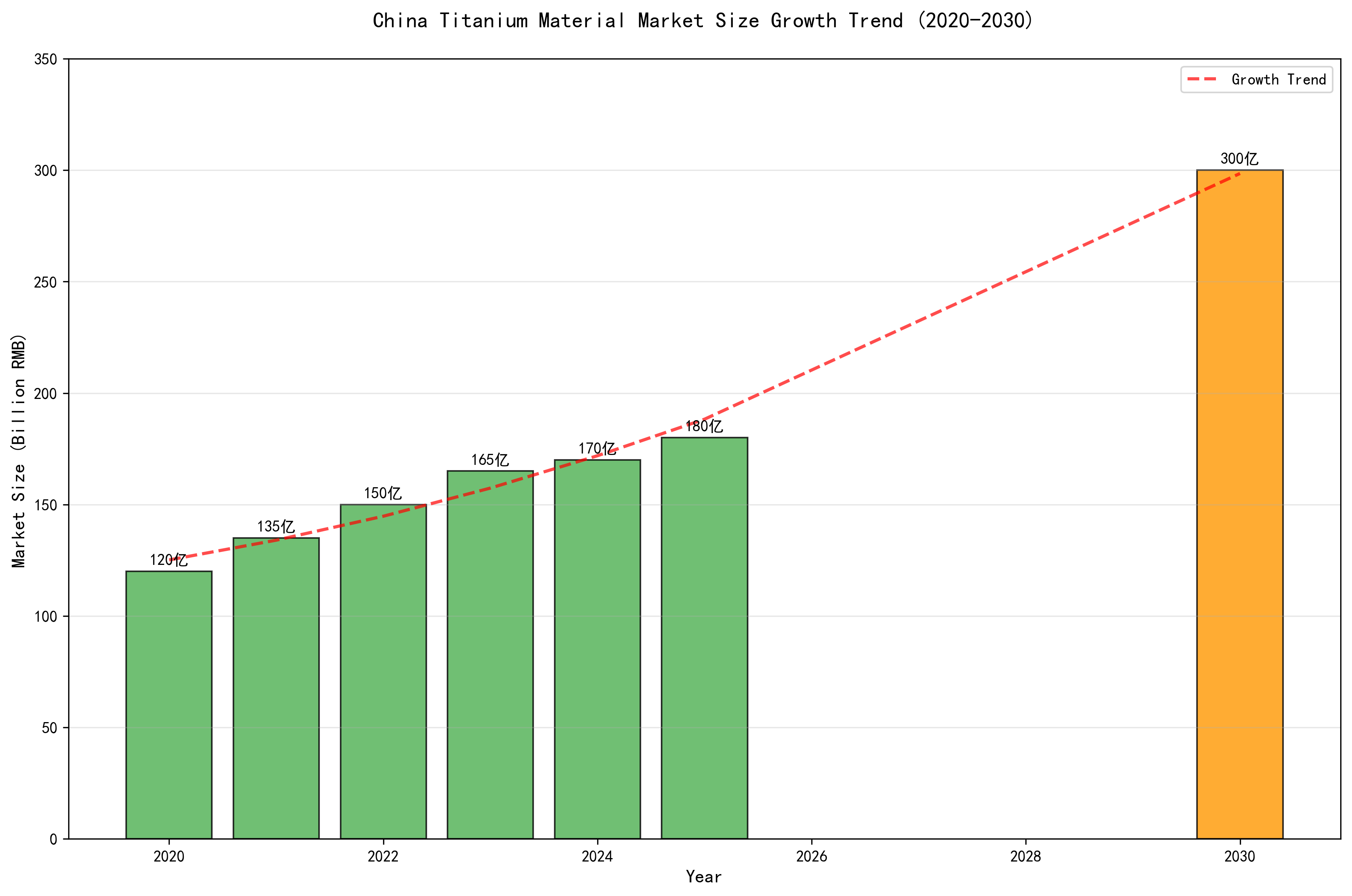

Market Growth Trend

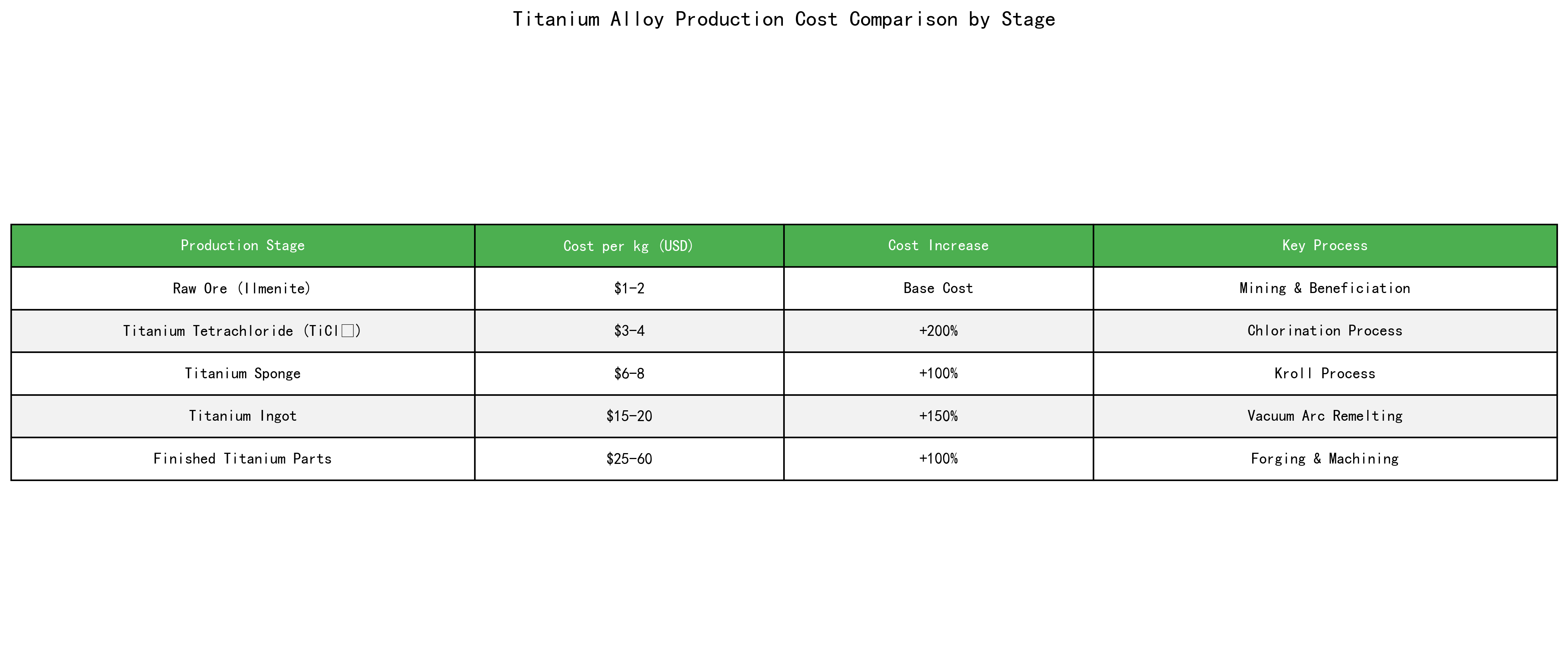

Production Cost Analysis

Key Challenges in Titanium Manufacturing

- High production costs due to complex multi-stage processes

- Reactivity issues – titanium readily reacts with oxygen, nitrogen at high temperatures

- Processing difficulties – low thermal conductivity and high strength

- Equipment requirements – specialized vacuum furnaces and protective atmospheres

Emerging Technologies

- Hydrogen Assisted Reduction: Promises 7x capacity increase and sub-$30/kg costs

- 3D Printing: Enables complex geometries with reduced material waste

- Near-net-shape forming: Powder metallurgy techniques for cost reduction

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.