Preventing rust on CNC stainless steel parts involves maintaining their passive oxide layer through material selection (e.g., 316 with molybdenum), post-machining treatments (passivation, electropolishing), avoiding surface damage during processing, using protective coatings, and controlling storage/handling environments (low humidity, anti-rust packaging). These steps counteract corrosion from machining residues, moisture, and harsh chemicals.

Detailed Analysis of Rust Prevention for CNC Stainless Steel Parts

1. Material Selection: Choosing Corrosion-Resistant Grades

Stainless steel’s rust resistance stems from its chromium content (≥10.5%), which forms a protective passive oxide film. Selecting the right grade is foundational:

- 304/304L Stainless Steel: Contains 18% chromium and 8% nickel, suitable for dry or mildly humid environments (e.g., kitchen equipment, indoor machinery). 304L (low carbon) resists intergranular corrosion during welding but is less durable in high-salt or acidic conditions.

- 316/316L Stainless Steel: Adds 2–3% molybdenum to enhance resistance to chloride-induced corrosion (e.g., marine environments, chemical processing). Ideal for CNC parts like shipboard hardware or wastewater treatment components, reducing rust risk by 50% vs. 304 in salt spray.

- Duplex Stainless Steels (2205): Combines austenitic and ferritic structures with 22% chromium, 5% nickel, and 3% molybdenum. Offers superior strength and corrosion resistance for high-stress, high-corrosion scenarios (e.g., oil & gas valves), with rust resistance 2–3x that of 304.

- Avoid Low-Grade Stainless Steels: Grades like 410 (martensitic, 11.5–13.5% chromium) lack sufficient nickel/molybdenum, making them prone to rust in humid environments—unsuitable for CNC parts requiring long-term durability.

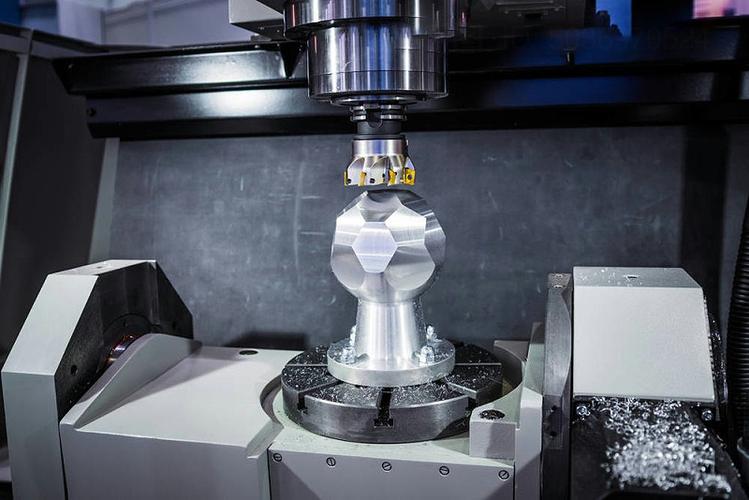

2. Machining Process Optimization to Protect Passive Film

Stainless steel’s passive layer (5–10nm thick) is easily damaged during CNC machining, exposing the base metal to corrosion. Process refinements prevent such damage:

-

Cutting Fluid Selection: Use chloride-free coolants (e.g., vegetable-based or synthetic fluids with EP additives) to avoid breaking down the passive film. Chloride-containing coolants (common in some metalworking fluids) react with chromium, weakening corrosion resistance—switching to chloride-free options reduces rust incidents by 60%.

-

Minimize Surface Damage:

- Low-Force Machining: High cutting forces (e.g., deep cuts in 316) cause work hardening, creating micro-cracks where rust initiates. Use sharp carbide tools (TiAlN-coated) with high speeds (10,000–15,000 RPM) and low feeds (0.05–0.1 mm/rev) to reduce deformation.

- Avoid Scratches & Burrs: Post-machining deburring (abrasive flow machining) and polishing (600-grit sandpaper) remove micro-irregularities where moisture traps—critical for parts with tight tolerances (e.g., hydraulic fittings).

-

Immediate Post-Machining Cleaning:

- Ultrasonic Cleaning: 40–60kHz ultrasonic baths with alkaline detergents (pH 8–10) remove cutting fluid residues, metal particles, and fingerprints (which contain corrosive salts). For complex parts (e.g., manifolds with deep holes), add a 5-minute rinse in deionized water to eliminate detergent traces.

- Drying: Use hot air (60–80°C) or vacuum drying to ensure no moisture remains—even small water droplets in crevices (e.g., thread roots) can cause pitting rust within 48 hours in humid environments.

3. Post-Treatment to Enhance Corrosion Resistance

Strengthening the passive film or adding protective layers further prevents rust:

-

Passivation:

- Nitric Acid Passivation: Immersing parts in 20–50% nitric acid (50–60°C for 20–30 minutes) dissolves free iron on the surface, thickening the chromium-rich oxide layer. Effective for 304/316 parts in general industrial use, doubling salt spray resistance (ASTM B117) to 1,000+ hours.

- Citric Acid Passivation: A safer, eco-friendly alternative (5–10% citric acid at 60–80°C) for food/medical applications (avoids nitric acid residues). Ideal for CNC parts like surgical instrument handles, meeting FDA and EU 10/2011 standards.

-

Electropolishing:

- This electrochemical process removes a thin surface layer (5–20μm), smoothing micro-irregularities and enriching chromium in the passive film. Parts like 316 marine connectors gain a mirror finish (Ra <0.05μm) and resist pitting in saltwater, with corrosion resistance 3x higher than untreated parts.

-

Protective Coatings:

- PVD Coatings: Titanium nitride (TiN) or chromium nitride (CrN) coatings (2–5μm thick) provide a physical barrier against moisture. Used for high-wear parts (e.g., valve stems) in humid environments, extending rust-free life by 5+ years.

- Epoxy/Paint Coatings: For non-aesthetic parts (e.g., structural brackets), UV-cured epoxy coatings (50–100μm) seal surfaces—ideal for outdoor applications (construction machinery) exposed to rain and dirt.

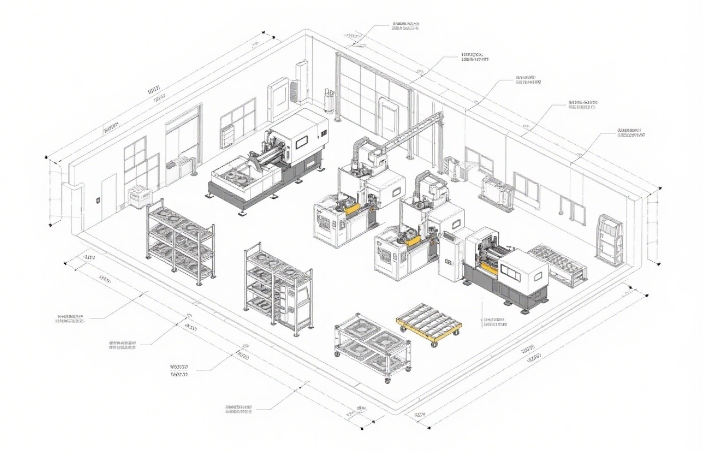

4. Storage & Handling Protocols

Even well-treated parts rust if mishandled, requiring strict storage controls:

-

Environment Control: Store parts in dry rooms (relative humidity <50%) with temperature stability (20±5°C). Use dehumidifiers and corrosion-inhibiting cabinets for long-term storage (3+ months), with humidity sensors triggering alerts if levels exceed 60%.

-

Packaging & Separation:

- Wrap parts in VCI (Volatile Corrosion Inhibitor) paper or bags—VCI molecules form a protective layer on metal surfaces, preventing rust for up to 2 years.

- Avoid direct contact between stainless steel and carbon steel (e.g., in bins), as carbon steel particles can transfer and initiate corrosion. Use plastic dividers or separate storage racks.

-

Handling Practices: Mandate clean, lint-free gloves (nitrile) to prevent fingerprint oils. Avoid placing parts on bare concrete floors (which retain moisture); use rubber mats or pallets elevated 10cm above the ground.

5. Industry-Specific Rust Prevention

Different sectors demand tailored strategies based on their corrosion risks:

-

Food & Beverage: Parts like CNC-machined mixing blades (304 stainless) use citric acid passivation to avoid toxic residues. Post-processing includes steam cleaning (121°C) to remove organic residues, preventing bacterial growth that accelerates corrosion.

-

Medical Devices: Surgical tools (316L) undergo electropolishing and passivation to meet biocompatibility standards (ISO 10993). Storage in sterile, sealed containers with VCI strips ensures rust resistance during sterilization cycles (autoclaving at 134°C).

-

Marine & Offshore: 316 stainless parts (e.g., boat hardware, oil rig connectors) require duplex passivation (nitric + hydrofluoric acid) to resist saltwater pitting. Additional sealants (polyurethane coatings) protect against galvanic corrosion from contact with aluminum or copper alloys.

-

Automotive: Exhaust components (409 stainless) use high-temperature-resistant coatings (ceramic-based) to withstand 600°C+ temperatures and road salt, preventing rust in undercarriage environments.

6. Troubleshooting Common Rust Issues

- Pitting Rust in Crevices: Caused by trapped moisture in threads or weld seams. Fix by: 1) Enlarging thread clearances for better drainage; 2) Using anti-seize compounds (copper-based) to fill gaps; 3) Ultrasonic cleaning followed by citric passivation.

- Fingerprint-Induced Rust: Occurs from skin oils on polished surfaces. Prevent with: 1) Post-machining cleaning with isopropyl alcohol; 2) Applying a temporary anti-fingerprint spray (silicone-based) before shipping.

- High-Temperature Rust: In parts like furnace components (310 stainless), use aluminum-rich coatings (aluminide) to form a stable oxide layer at 800–1,000°C, resisting scale and rust.

By integrating material selection, process optimization, post-treatments, and industry-specific protocols, CNC stainless steel parts can achieve long-term rust resistance—ensuring reliability in environments from kitchens to offshore platforms.