- 3D model quality (topology, geometry);

- Technology selection (FDM, SLA, SLS, etc.);

- Process control (slicing parameters, material handling, post-processing).

1. Preparatory Stage: Digital Model Design & Validation

1.1 3D Model Sources

|

Source Type

|

Examples

|

Pros

|

Cons

|

|

DIY Design

|

CAD software (SolidWorks, Fusion 360, Tinkercad)

|

Fully customizable for specific needs

|

Requires CAD expertise; time-consuming

|

|

Downloaded Models

|

Platforms (Thingiverse, MyMiniFactory, Printables)

|

Ready-to-print; free/low-cost

|

May need repair (e.g., non-manifold geometry)

|

|

3D Scanning

|

Desktop scanners (Ender 3 V3 SE Scanner, Artec Eva)

|

Replicates physical objects accurately

|

Scanning errors (e.g., missing details)

|

1.2 Critical Model Validation Checks

- Topology Correctness:

-

- No “non-manifold edges” (edges shared by >2 faces—causes slicing errors).

-

- No “free faces” (faces not connected to the model body—prints as floating fragments).

-

- Fix with software: Meshlab (free), Blender (free), or MeshMixer (free) → Use “Make Manifold” or “Repair Geometry” tools.

- Wall Thickness:

-

- Minimum thickness depends on technology (e.g., FDM: ≥0.8mm for PLA; SLA: ≥0.2mm for resin).

-

- Use “Shell Thickness” tool in CAD to check—thin walls collapse during printing.

- Overhangs & Supports:

-

- Overhangs >45° (FDM) or >60° (SLA) require support structures (prevents layer sagging).

-

- Avoid “bridges” (horizontal spans) longer than 10mm (FDM) or 20mm (SLA)—add internal supports if needed.

- File Format:

-

- Export as STL (Standard Tessellation Language) (most common) or 3MF (3D Manufacturing Format) (supports color/material data).

-

- STL settings: Use 0.1–0.2mm “triangle tolerance” (balances detail and file size—too many triangles slow slicing).

2. Technology Selection: Choose the Right 3D Printing Method

|

Technology

|

Core Principle

|

Material Type

|

Precision (Layer Height)

|

Strength

|

Cost Range

|

Best For

|

|

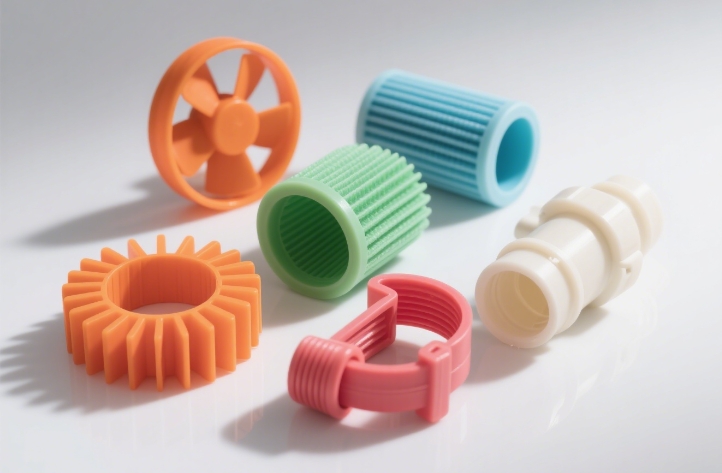

FDM (Fused Deposition Modeling)

|

Melts thermoplastic filament; extrudes layer-by-layer

|

PLA, ABS, PETG, TPU

|

0.1–0.3mm

|

Moderate

|

Desktop: (200–)2,000Industrial: (10k–)100k

|

Hobbies, prototypes, low-strength parts (e.g., toy cars)

|

|

SLA (Stereolithography)

|

UV light cures liquid 光敏树脂 (photopolymer) layer-by-layer

|

Standard resin, flexible resin, high-temp resin

|

0.025–0.1mm

|

Low-Moderate

|

Desktop: (300–)3,000Industrial: (20k–)200k

|

High-detail parts (e.g., jewelry, dental models)

|

|

SLS (Selective Laser Sintering)

|

Laser sinters polymer powder (no supports needed)

|

Nylon 12, Nylon 11, TPU powder

|

0.05–0.2mm

|

High

|

Industrial: (50k–)500k

|

High-strength industrial parts (e.g., gears, brackets)

|

|

MJF (Multi Jet Fusion)

|

Inkjet deposits fusing agent on powder; heated roller sinters

|

Nylon 12, PA12 GF (glass-filled)

|

0.08–0.15mm

|

Very High

|

Industrial: (100k–)1M

|

Mass-produced high-performance parts (e.g., aerospace components)

|

3. Step-by-Step Printing Workflow (By Technology)

3.1 FDM Printing Workflow (Most Common for Beginners)

Step 1: Gather Equipment & Materials

- Printer: Desktop FDM (e.g., Creality Ender 3 V3 SE, Prusa Mini+); ensure it has a heated bed (critical for ABS/PETG).

- Filament: Choose based on use case (PLA for beginners: low warping, 190–220℃ printing temp; PETG for durability: 220–250℃).

- Tools: Filament cutter, nozzle cleaning kit (needle, wire brush), leveling tool (feeler gauge), adhesive (blue tape, hairspray—for bed adhesion).

Step 2: Printer Setup & Calibration

- Bed Leveling:

-

- Manual leveling: Adjust bed screws until a feeler gauge (0.1mm) slides between nozzle and bed with slight resistance.

-

- Auto-leveling (e.g., BLTouch sensor): Run the printer’s auto-level routine—ensures bed is flat across the entire surface (critical for first-layer adhesion).

- Nozzle & Bed Temperature Calibration:

-

- PLA: Nozzle 190–220℃, Bed 50–60℃.

-

- ABS: Nozzle 230–250℃, Bed 90–110℃ (use an enclosure to reduce warping).

-

- Test: Print a “temperature tower” (pre-made STL) to find the optimal nozzle temp (minimizes stringing/under-extrusion).

- Extruder Calibration:

-

- Measure 100mm of filament, feed it into the extruder, and command the printer to extrude 100mm.

-

- If only 95mm extrudes: Adjust the extruder steps/mm in the printer’s firmware (increase by ~5%).

Step 3: Slice the 3D Model

- Software: Use Cura (free, most popular) or PrusaSlicer (optimized for Prusa printers).

- Key Slicing Parameters (PLA Example):

|

Parameter

|

Setting

|

Purpose

|

|

Layer Height

|

0.2mm

|

Balances speed (fast) and detail (good)

|

|

Infill Density

|

20–50%

|

20% for decorative parts; 50% for structural

|

|

Infill Pattern

|

Grid/Grid 2.0

|

Even strength distribution

|

|

Support Type

|

Tree Supports

|

Saves material vs. normal supports

|

|

Print Speed

|

50–60 mm/s

|

Reduces vibration (better layer adhesion)

|

|

Retraction Distance

|

2–4 mm

|

Prevents stringing (filament oozing)

|

- Export: Save sliced file as G-code (printer-readable format) and transfer to the printer via USB, SD card, or Wi-Fi.

Step 4: Start Printing & Monitor

- Load Filament:

-

- Heat nozzle to printing temp (e.g., 200℃ for PLA), feed filament until it oozes smoothly from the nozzle.

- First-Layer Check (Most Critical):

-

- Watch the first layer—filament should adhere firmly to the bed, with no gaps or lifting (if lifting occurs: increase bed temp by 5℃ or add adhesive).

- Mid-Print Monitoring:

-

- Check for:

-

-

- Stringing (thin plastic strands between features): Increase retraction by 0.5mm.

-

-

-

- Layer separation: Increase nozzle temp by 5℃ or slow print speed.

-

-

-

- Nozzle clogging: Pause print, heat nozzle to 250℃, and push filament through to clear the blockage.

-

Step 5: Post-Processing

- Remove Supports: Use pliers or a support removal tool—pull gently to avoid damaging the part.

- Trim & Sand: Cut off excess filament (e.g., brims) with a utility knife; sand rough edges with 200–800 grit sandpaper.

- Finish (Optional): Paint with acrylic paint (PLA/ABS) or use acetone vapor smoothing (ABS only—creates a glossy surface).

3.2 SLA Printing Workflow (High-Detail Parts)

Step 1: Gather Equipment & Materials

- Printer: Desktop SLA (e.g., Elegoo Mars 4, Anycubic Photon M5); ensure it has a UV light source (405nm for standard resin).

- Resin: Standard resin (for prototypes), flexible resin (for hinges), or high-temp resin (for molds); use nitrile gloves when handling.

- Tools: Resin vat (with FEP film), isopropyl alcohol (IPA, 90%+ concentration—for cleaning), curing station (UV light—for post-curing), plastic scraper.

Step 2: Printer Setup & Resin Preparation

- Vat Preparation:

-

- Inspect the FEP film (bottom of the vat) for scratches—replace if damaged (scratches cause resin leaks).

-

- Pour resin into the vat (fill to 1–2mm below the max line—overfilling causes spills).

- Build Plate Calibration:

-

- Lower the build plate until it touches the FEP film, then raise it by the layer height (e.g., 0.05mm)—ensures the first layer cures properly.

Step 3: Slice the 3D Model

- Software: Use Chitubox (free, SLA-optimized) or Lychee Slicer.

- Key Slicing Parameters (Standard Resin Example):

|

Parameter

|

Setting

|

Purpose

|

|

Layer Height

|

0.05mm

|

High detail (smooth surfaces)

|

|

Bottom Layers

|

5–10

|

Thicker layers (2x normal) for bed adhesion

|

|

Bottom Layer Exposure Time

|

30–60s

|

Longer cure time (secures part to build plate)

|

|

Normal Layer Exposure Time

|

2–5s

|

Fast curing (avoids overexposure)

|

|

Support Density

|

50–70%

|

Strong enough to hold parts (prevents sagging)

|

- Export: Save as CLI/CTB (SLA-specific G-code) and transfer to the printer.

Step 4: Start Printing & Post-Cleaning

- Print Monitoring:

-

- SLA prints are slower than FDM (e.g., 4 hours for a 10cm part); no mid-print adjustments needed (resin cures automatically).

- Remove Part from Build Plate:

-

- After printing, remove the build plate, use a plastic scraper to gently pry the part off (avoid metal scrapers—damages the plate).

- Resin Cleaning:

-

- Dip the part in IPA (90%+) for 5–10 minutes, then scrub gently with a soft brush to remove excess resin.

-

- Let the part air-dry for 10–15 minutes (residual IPA causes cloudiness if not dried).

Step 5: Post-Curing & Finishing

- Post-Curing:

-

- Place the part in a UV curing station (365–405nm) for 5–15 minutes—full curing improves strength (resin is 70% cured after printing).

- Support Removal: Use flush cutters to trim supports—sand cut areas with 400–1000 grit sandpaper.

- Polishing (Optional): Use a polishing compound (e.g., Turtle Wax) to buff the part for a mirror finish.

4. Industrial-Grade Workflows (SLS/MJF)

- Prep: Use professional CAD software (e.g., SolidWorks Professional) to design parts with “sintering-friendly” geometry (no sharp edges—causes powder clumping).

- Print: SLS uses a CO₂ laser (10.6μm wavelength) to sinter nylon powder; MJF uses inkjet nozzles to deposit fusing agent (faster than SLS for high volume).

- Finish: Remove excess powder with a vacuum or compressed air, then use bead blasting (nylon beads) to smooth surfaces. For strength, post-process with heat treatment (e.g., annealing nylon 12 at 120℃ for 2 hours).

5. Decision Framework: How to Choose the Right Workflow

Step 1: Define Part Requirements

|

Requirement

|

Priority Technology

|

Material

|

|

Low cost + hobby use

|

FDM

|

PLA

|

|

High detail (e.g., jewelry)

|

SLA

|

Standard resin

|

|

High strength (e.g., gears)

|

SLS/MJF

|

Nylon 12

|

|

Flexible parts (e.g., hinges)

|

FDM/SLA

|

TPU (FDM), flexible resin (SLA)

|

Step 2: Set Budget

- **<(500**: FDM printer (e.g., Ender 3 V3 SE) + PLA filament ()20/kg) → Ideal for beginners.

- (500–)2,000: SLA printer (e.g., Elegoo Mars 4) + resin ($50/L) → High-detail prototypes.

- >$10k: Industrial FDM/SLS → Small-batch production.

Step 3: Validate with Prototypes

- Print a small test part (e.g., a 5cm cube) first—check for:

-

- Dimensional accuracy (use calipers to compare printed vs. digital size).

-

- Strength (apply pressure to test for breaking—adjust infill if needed).

-

- Surface quality (no layer lines/scratches—tweak layer height or post-processing).

6. Common Myths & Misconceptions

Myth 1: “3D models can be printed directly from CAD without fixes.”

Myth 2: “Lower layer height = better part quality.”

Myth 3: “SLA resin is unsafe to use at home.”

Myth 4: “FDM parts are always weak.”

7. Industry Case Studies

Case 1: Hobbyist Toy Replica (FDM)

- Goal: Print a 1:24 scale car model (detail + low cost).

- Workflow:

-

- Download STL from Thingiverse → Repair non-manifold edges in MeshMixer.

-

- Slice in Cura: 0.2mm layer height, 30% infill, tree supports.

-

- Print with PLA (200℃ nozzle, 60℃ bed) → Post-process: Sand edges, paint with acrylics.

- Result: 4-hour print, $2 material cost, detailed enough for display.

Case 2: Dental Crown Prototype (SLA)

- Goal: High-precision crown model (fit for patient testing).

- Workflow:

-

- Scan patient’s tooth → Design crown in CAD (Exocad Dental).

-

- Slice in Chitubox: 0.025mm layer height, 10 bottom layers (60s exposure).

-

- Print with dental resin (405nm UV) → Clean with IPA, post-cure for 10 minutes.

- Result: 2-hour print, ±0.1mm precision, fits patient’s mouth perfectly.

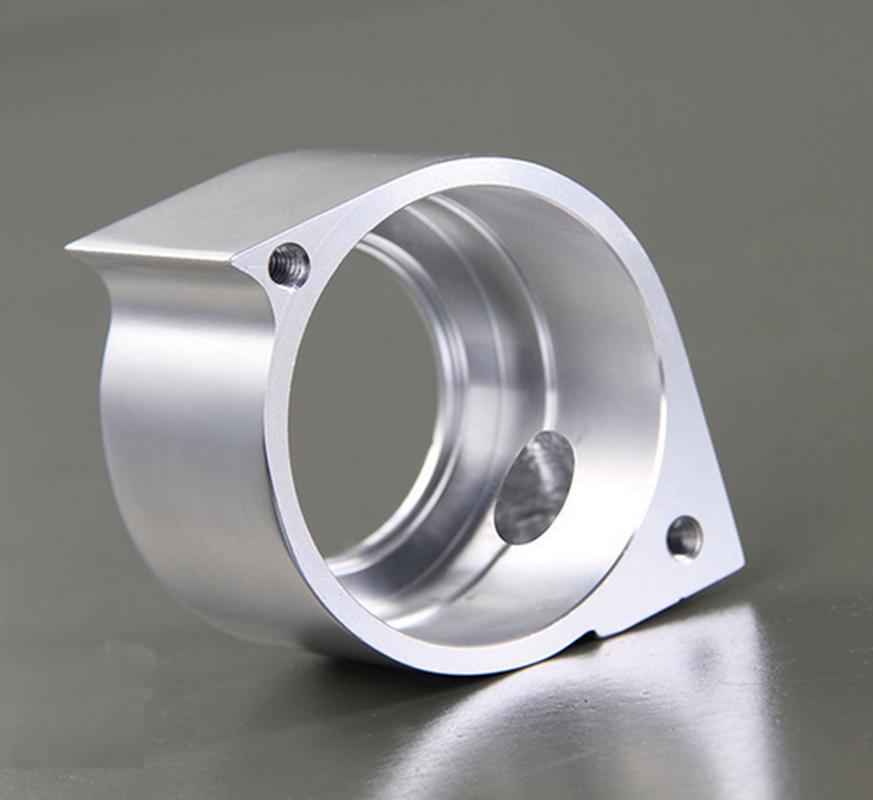

Case 3: Industrial Gear (SLS)

- Goal: High-strength gear for a conveyor system (load-bearing + durability).

- Workflow:

-

- Design gear in SolidWorks (10mm thickness, 20 teeth) → Optimize for SLS (no sharp edges).

-

- Print with nylon 12 (0.1mm layer height, 100% infill) → Post-process: Anneal at 120℃ for 2 hours.

- Result: 8-hour print, withstands 50N load (equivalent to metal gears), 30% lighter than steel.