Custom CNC Aerospace Parts Production Guide 2026 | Goldcattle Precision Solutions

Goldcattle’s Custom CNC Aerospace Parts Service delivers AS9100-certified components with ±0.001mm precision, tailored to your unique aerospace, UAV, and spacecraft requirements. Our 5-axis machining capabilities handle titanium alloys, Inconel, and CFRP materials, ensuring compliance with FAA/EASA standards.

As a leading custom precision manufacturer, we combine 15 years of aerospace experience with flexible production workflows to meet your exact design specifications and tight delivery schedules.

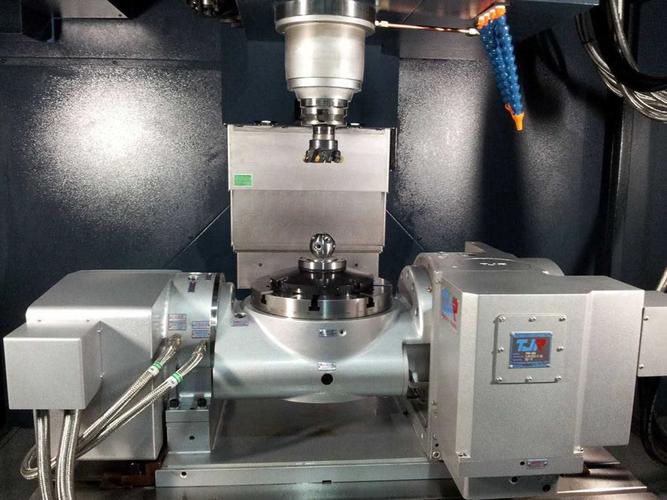

Custom 5-Axis CNC Machining for Aerospace Components

Custom Precision Machining

Custom Precision Machining

Tailored ±0.001mm precision components, customized to your CAD design specifications. Real-time process monitoring ensures consistency across small-batch and large-scale custom orders.

Custom Material Solutions

Custom Material Solutions

Deep expertise in custom machining of titanium alloys, nickel-based superalloys, and CFRP. We optimize material selection and cutting parameters for your specific application requirements.

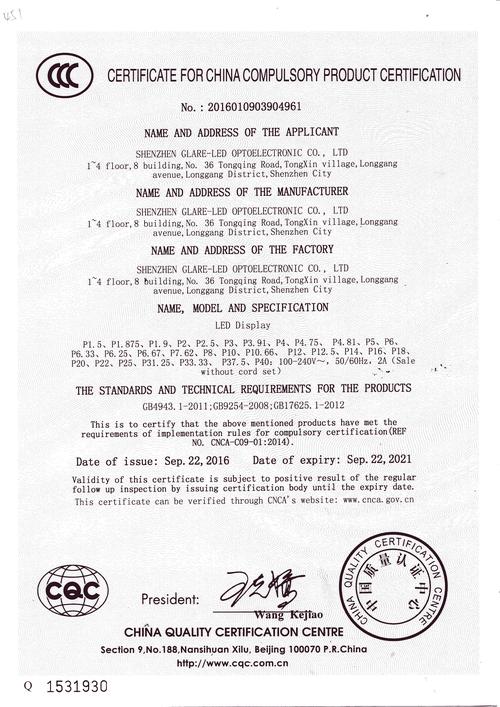

Custom Certification Compliance

Custom Certification Compliance

AS9100, NADCAP, FAA/EASA compliant custom production with full traceability. We provide customized documentation packages to meet your regulatory requirements.

1. Custom Technical Requirements for CNC Aerospace Parts

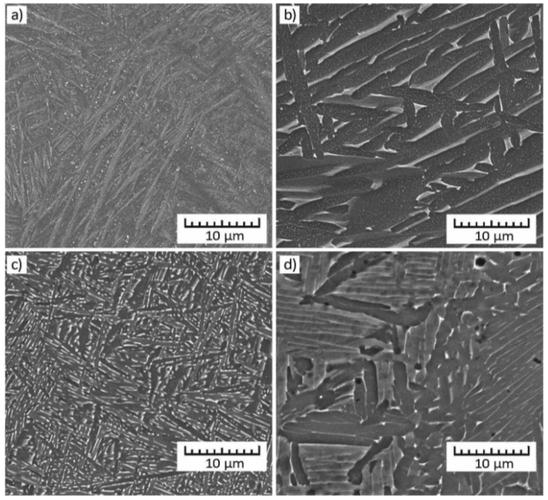

1.1 Custom Precision & Tolerance Standards

Goldcattle tailors precision levels to your specific component needs, from ±0.001mm for critical structural parts to ±0.01mm for non-critical components. Surface finish requirements are customized to your application, with Ra values ranging from 0.4μm to 3.2μm.

Goldcattle Custom Project Case (2025): For a UAV client requiring custom Ti-6Al-4V wing components, we implemented adaptive tool path adjustments to maintain consistent ±0.001mm tolerances, improving first-pass yield by 23% compared to standard production workflows.

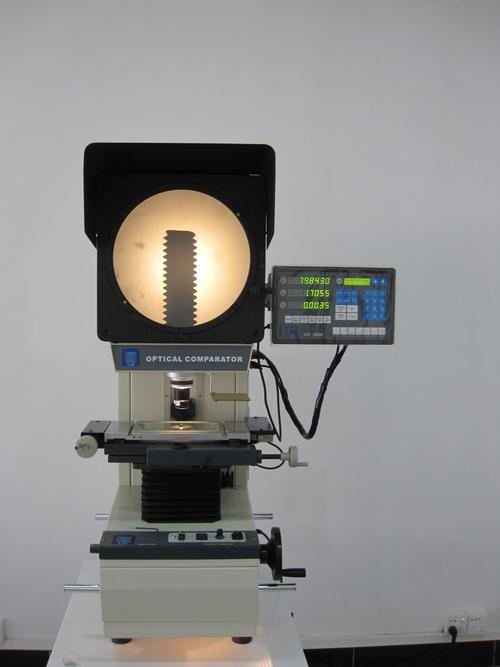

Custom Tolerance Inspection for Aerospace Components

1.2 Custom Material Specifications

Custom Ti-6Al-4V Aerospace Component

Custom Ti-6Al-4V Aerospace Component

Custom Inconel 718 High-Temp Component

Custom Inconel 718 High-Temp Component

Custom CFRP Composite Aerospace Panel

Custom CFRP Composite Aerospace Panel

2. Goldcattle’s Custom CNC Aerospace Machining Process

Step 1: Design Validation & DFM Analysis

Our engineering team reviews your custom CAD designs to optimize manufacturability, identify potential machining challenges, and recommend design modifications to reduce costs while maintaining performance. This custom DFM analysis is tailored to your specific component requirements.

Goldcattle Custom Insight: Investing in custom DFM analysis reduces production time by 30-40% and eliminates costly design changes during manufacturing.

Step 2: Material Inspection & Certification

We source custom materials to your exact specifications, with full certification and traceability. Our incoming inspection process includes chemical composition analysis, ultrasonic testing, and mechanical property verification to ensure compliance with your material requirements.

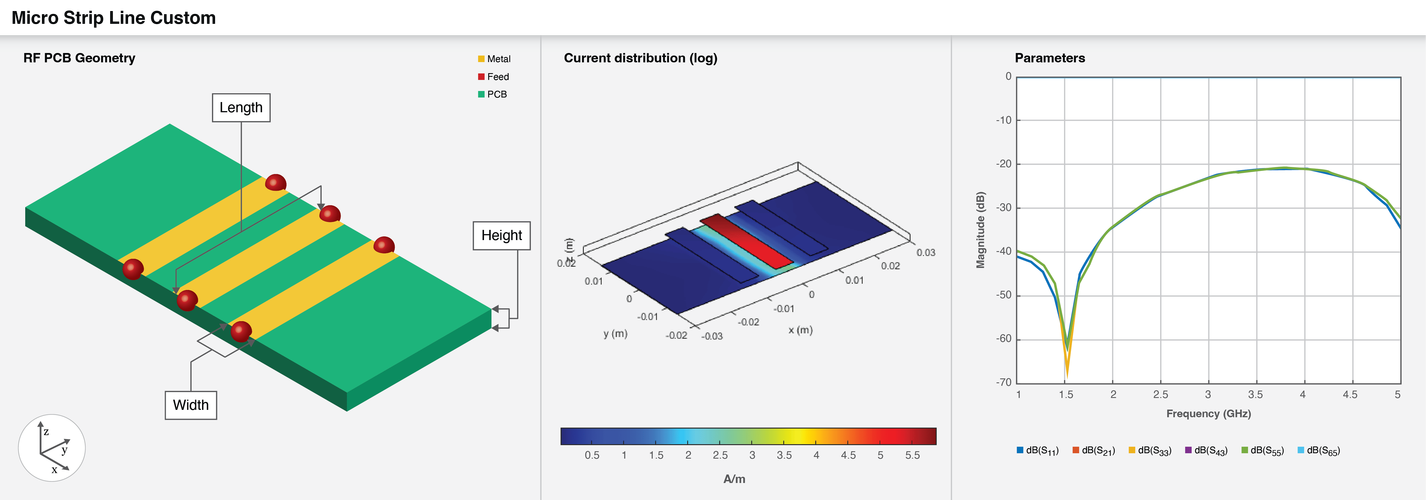

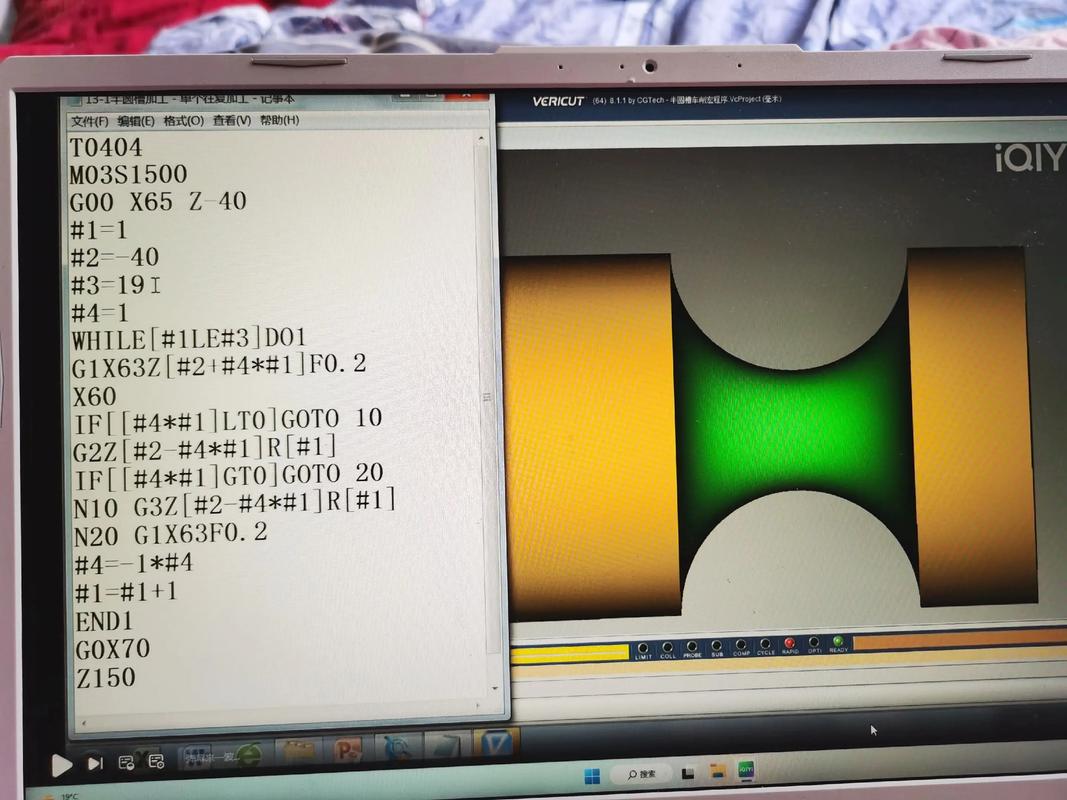

Step 3:CNC Programming & Simulation

Our programmers create custom CNC tool paths optimized for your specific component geometry, material, and tolerance requirements. Virtual machining simulation identifies potential collisions and optimizes cutting parameters to ensure first-pass success.

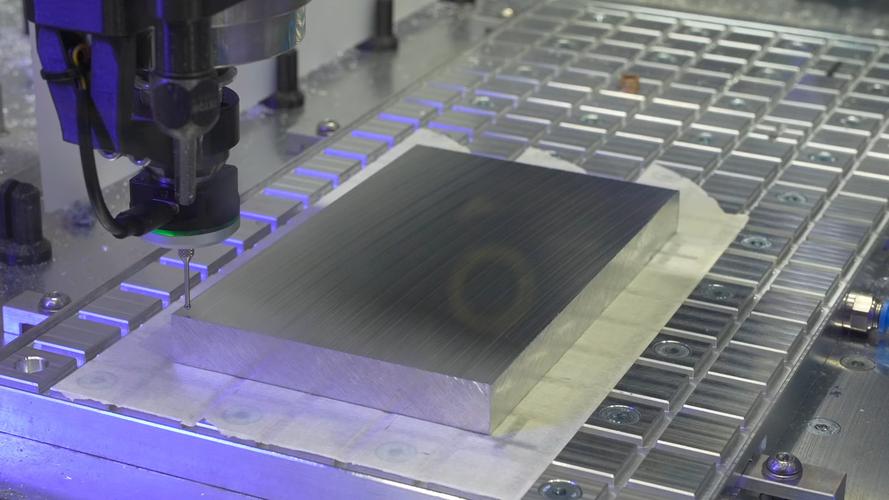

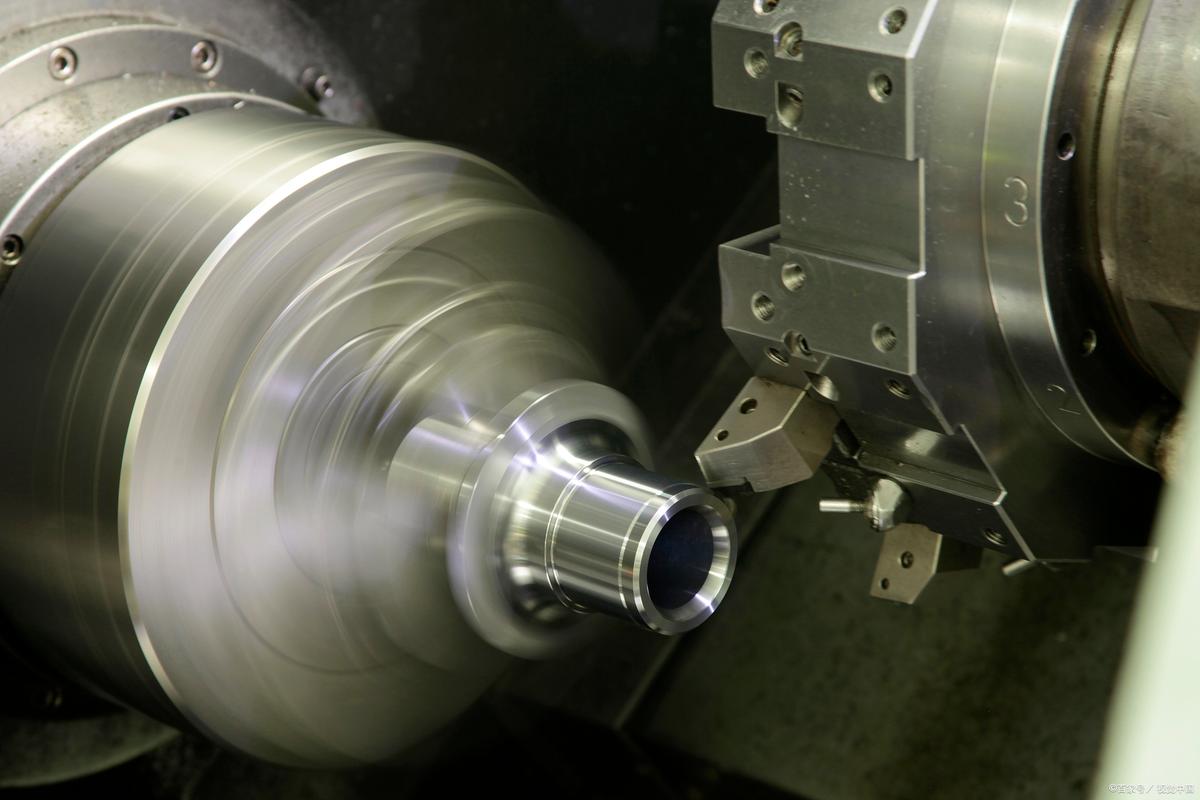

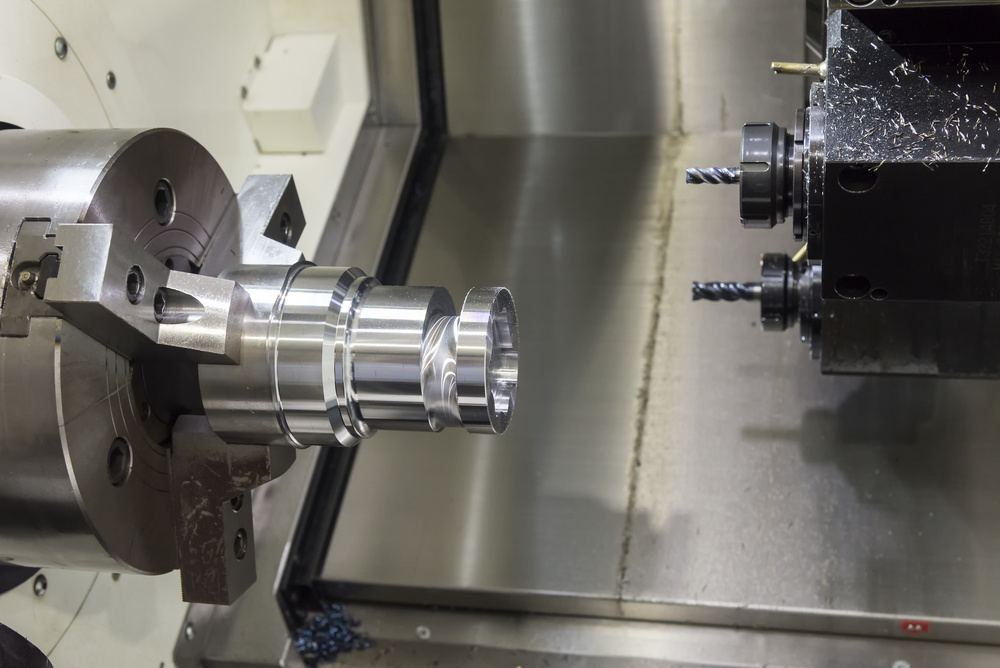

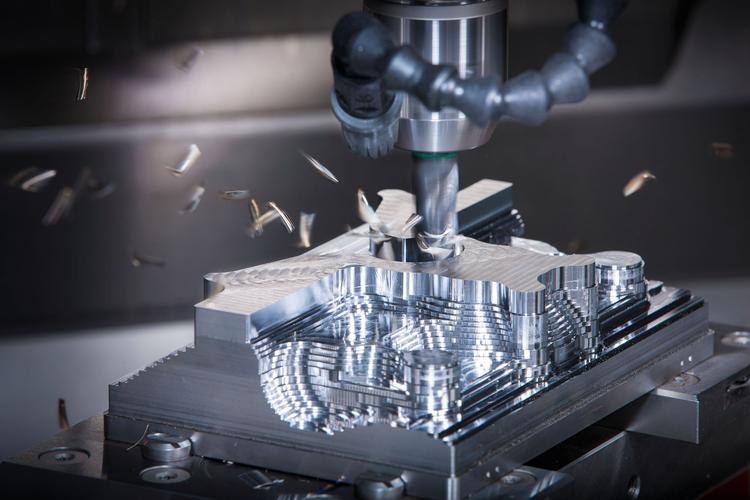

Step 4: Precision Machining

Using our 5-axis CNC machines, we perform custom roughing, semi-finishing, and finishing operations tailored to your component. Real-time process monitoring ensures consistent quality throughout production.

Custom Technical Detail: For custom Ti-6Al-4V components, we use carbide tools with TiAlN coatings, cutting speeds of 60-100 m/min, and feed rates optimized for your specific part geometry.

Step 5: Heat Treatment

We provide custom heat treatment processes tailored to your material and application requirements. For titanium alloys, this includes solution treatment and aging at precise temperatures (±1°C) to optimize strength and fatigue resistance.

Step 6:Quality Inspection & Testing

Our custom quality inspection process includes CMM measurement, ultrasonic testing, fluorescent penetrant inspection, and eddy current testing, tailored to your component’s critical features and regulatory requirements.

3. Goldcattle Custom CNC Aerospace Project Case Study (2025)

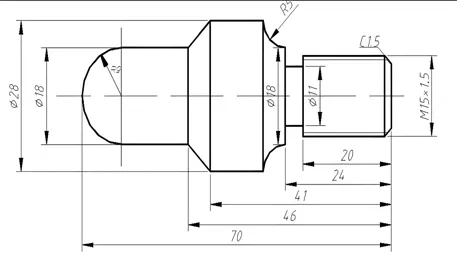

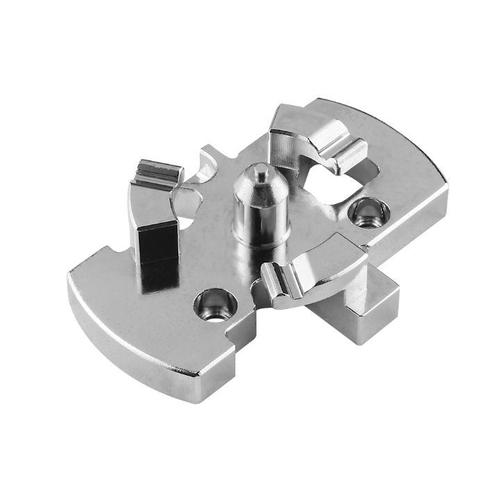

Custom Ti-6Al-4V Valve Components for Commercial Aerospace

Goldcattle was contracted to produce 500 custom Ti-6Al-4V valve components for a commercial aerospace client. The project required complex internal geometries with ±0.002mm tolerances, Ra 0.8μm surface finish, and a fatigue life of 35,000+ cycles, with an 8-week delivery schedule.

Custom Success Factors: Implementation of our proprietary 5-axis machining strategy, real-time process monitoring, and optimized tooling selection tailored to the client’s valve design. The project was completed 0.8 weeks ahead of schedule with exceptional quality results.

Custom Ti-6Al-4V Valve Component Produced by Goldcattle

Custom Ti-6Al-4V Valve Component Produced by Goldcattle

4. Custom Cost Calculation for CNC Aerospace Parts

Custom Cost Calculator Example (Ti-6Al-4V Component)

Goldcattle provides transparent custom cost estimates based on your component’s complexity, material, quantity, and tolerance requirements. The total cost formula for custom parts is:

Custom Cost Breakdown Example (500-Piece Order):

- Custom Material Cost: $120 per unit (2 kg Ti-6Al-4V, volume discount applied)

- Custom Machine Time Cost: $180 per unit (6 hours at $30/hour, optimized for batch production)

- Labor Cost: $90 per unit (3 hours at $30/hour)

- Custom Tooling Cost: $40 per unit (specialized carbide tools, amortized over 500 units)

- Overhead Rate: 50% ($215 per unit)

- Custom QC Cost: $45 per unit (CMM inspection, NDT testing)

- Certification Cost: $30 per unit (AS9100 documentation, traceability)

- Total Custom Unit Cost: $720 (20% lower than small-batch custom order)

Custom cost example shown is for reference only. Actual costs vary based on your specific design, quantity, and certification requirements.

5. Custom CNC Aerospace Parts for Drones, Spacecraft & Aviation

Custom UAV Components

Custom UAV Components

Lightweight, high-strength custom components for commercial and military drones. We tailor designs to your UAV’s payload capacity, flight time, and environmental requirements.

Custom Spacecraft Components

Extreme precision custom components for satellites and spacecraft. Our custom machining processes ensure reliability in the harsh environment of space.

Custom Rocket Components

Critical custom structural and engine components for launch vehicles. We tailor designs to meet your rocket’s thrust, weight, and reliability requirements.

6. Why Choose Goldcattle’s Custom CNC Aerospace Services?

- Custom Precision Engineering: Tailored solutions from concept to production, with ±0.001mm precision for critical components.

- Custom Material Expertise: Deep knowledge of titanium alloys, Inconel, and CFRP, with customized machining strategies for each material.

- Custom Certification Compliance: AS9100, NADCAP, FAA/EASA certified production with customized documentation packages.

- Custom Production Flexibility: Small-batch to large-scale custom orders, with flexible delivery schedules to meet your project timeline.

- Custom Cost Optimization: DFM analysis and process optimization to reduce your custom part costs without compromising quality.