In-Depth Analysis: How Much Does It Cost to CNC a Part?

A comprehensive technical analysis of CNC machining costs in 2026 – from cost drivers to optimization strategies

Executive Summary

CNC machining costs are determined by a complex interplay of factors including material selection, part complexity, production volume, tolerance requirements, and machine capabilities. This analysis provides a data-driven framework for understanding these cost drivers and optimizing your CNC manufacturing projects.

Key Findings

- Machining time represents 30-50% of total costs

- Material costs vary 50x between plastics and titanium

- Economies of scale reduce per-unit costs by 30-60%

- DFM optimization can save 20-40% on average

2026 Trends

- AI programming reduces setup time by 10-15%

- Titanium prices up 8-12% YoY due to aerospace demand

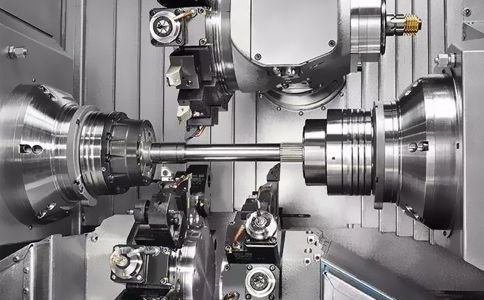

- 5-axis machining adoption increasing for complex parts

- Sustainability requirements adding 5-10% to material costs

Cost Component Analysis

CNC machining costs can be broken down into several distinct components, each with varying degrees of impact on the total price. Understanding these components is essential for cost optimization.

CNC machining cost breakdown by component

Material Costs (25-40%)

Raw material costs include the material itself plus waste allowance (typically 10-30% depending on part geometry).

Cost Range by Material

- ABS Plastic: $2-5/kg

- Aluminum 6061: $3-8/kg

- Steel 1018: $1-3/kg

- Stainless Steel 304: $4-10/kg

- Titanium Ti-6Al-4V: $40-120/kg

Material selection is one of the most impactful cost decisions. Choosing the right material for your application can significantly reduce costs.

Machining Time (30-50%)

Machine time is calculated based on hourly rates multiplied by the total machining time required for the part.

Machine Hourly Rates (2026)

- 3-axis CNC Mill: $60-120/hr

- 4-axis CNC Mill: $100-200/hr

- 5-axis CNC Mill: $220-550/hr

- CNC Lathe: $80-180/hr

Machining time depends on part complexity, material machinability, and cutting parameters. Optimizing tool paths can reduce time by 15-30%.

Labor Costs (15-25%)

Labor includes programming, setup, monitoring, and quality control. Skilled CNC operators command higher wages.

Labor Cost Breakdown

- Programming: 30-40%

- Setup: 20-30%

- Monitoring: 15-25%

- Quality Control: 10-20%

Automation and AI programming are reducing labor costs by 10-15% annually as technology advances.

Setup Costs (5-15%)

Setup includes fixturing, tooling, and machine preparation. These costs are amortized over the production run.

Typical Setup Times

- Simple parts: 1-2 hours

- Complex parts: 3-8 hours

- 5-axis parts: 8-16 hours

Modular fixturing systems can reduce setup time by 40-60% for repeat orders.

Key Cost Drivers

Several factors significantly influence CNC machining costs. Understanding these drivers allows for strategic cost optimization.

Relative impact of different factors on CNC machining costs

Part Complexity

Complex geometries with multiple features, deep pockets, and tight tolerances significantly increase machining time and cost.

Complexity Cost Factors

- Number of features: +5-15% per additional feature

- Depth-to-diameter ratio: +10-30% for ratios >3:1

- Internal corners: +15-40% for radii < tool diameter

- Undercuts: +50-200% requiring special tooling

Design simplification can reduce costs by 20-50% while maintaining functionality.

Tolerance Requirements

Tighter tolerances require slower feeds, more precise machines, and additional quality control.

Tolerance Cost Multipliers

- Standard (±0.1mm): 1.0x

- Precision (±0.01-0.05mm): 2.0-4.0x

- High Precision (±0.001-0.01mm): 5.0-15.0x

Specifying only the tolerances you truly need can save significant costs.

Production Quantity

Economies of scale significantly reduce per-unit costs for larger production runs.

Quantity Cost Reductions

- 1-10 pieces: Highest cost

- 11-100 pieces: 15-30% reduction

- 101-1,000 pieces: 30-50% reduction

- 1,000+ pieces: 40-60% reduction

Consolidating orders or planning for future needs can leverage volume discounts.

Material Selection

Material cost and machinability have a profound impact on total costs.

Machinability Ratings

- Aluminum 6061: Excellent (1.0x)

- Steel 1018: Good (1.5x)

- Stainless Steel 304: Fair (3.0x)

- Titanium Ti-6Al-4V: Poor (10.0x)

Choosing the right material for your application balance performance and cost.

Cost Calculation Methodology

A systematic approach to calculating CNC machining costs ensures accurate budgeting and cost optimization.

Step-by-step cost calculation process

CNC Cost Calculation Formula

Step 1: Material Cost Calculation

- Calculate part volume from CAD model

- Multiply by material density to get weight

- Multiply by material price per unit weight

- Add scrap allowance (10-30%)

Step 2: Machining Time Estimation

- Analyze part geometry and features

- Estimate cutting time for each feature

- Add tool change and non-cutting time

- Calculate total cycle time per part

Step 3: Setup and Labor Costs

- Estimate programming time (2-8 hours)

- Calculate setup time (1-16 hours)

- Add quality control and inspection time

- Multiply by labor rates

Step 4: Final Cost Calculation

- Sum all cost components

- Apply quantity discounts if applicable

- Add shipping and handling costs

- Include any additional services (finishing, certification)

Cost Optimization Strategies

Implementing these strategies can significantly reduce CNC machining costs while maintaining quality and performance.

Design for Manufacturing (DFM)

- Simplify part geometry where possible

- Use standard tolerances unless critical

- Design for minimal tool changes

- Avoid deep pockets and small internal radii

Material Optimization

- Choose the most cost-effective material that meets requirements

- Consider aluminum over titanium where possible

- Use plastics for non-structural components

- Optimize material utilization to reduce waste

Production Optimization

- Consolidate orders to reach economic batch sizes

- Plan for future needs to leverage volume discounts

- Use inventory management to optimize ordering

- Consider offshore manufacturing for cost savings

Technology Optimization

- Use AI CAM software for optimal tool paths

- Implement modular fixturing systems

- Leverage automation for repetitive tasks

- Optimize cutting parameters for efficiency

Optimization Success Story

A medical device manufacturer approached us with a complex titanium component costing $450 per part. Through DFM optimization, material selection review, and production planning, we were able to:

- Simplify part geometry, reducing machining time by 35%

- Switch to a more cost-effective titanium alloy, reducing material costs by 20%

- Consolidate orders to 500 pieces, leveraging volume discounts

Result: Cost per part reduced to $280 (38% savings), with no impact on performance or quality.

Real-World Cost Case Studies

These case studies illustrate how different factors impact CNC machining costs in real manufacturing scenarios.

Case Study 1: Simple ABS Enclosure

Project Details

- Material: ABS Plastic

- Size: 150×100×50mm

- Quantity: 50 pieces

- Tolerance: ±0.1mm

- Surface Finish: Matte

Cost Breakdown

- Material: $2.50 per part

- Machining: $8.00 per part

- Setup: $0.50 per part

- Total: $11.00 per part

Key Learnings

This simple plastic part demonstrates how material choice and part complexity drive costs. ABS is an affordable, easy-to-machine material, and the simple geometry keeps machining time low. The small production run means setup costs are a significant portion of the total.

Case Study 2: Titanium Aerospace Bracket

Project Details

- Material: Titanium Ti-6Al-4V

- Size: 200×150×80mm

- Quantity: 20 pieces

- Tolerance: ±0.02mm

- Surface Finish: Ra 1.6μm

Cost Breakdown

- Material: $120.00 per part

- Machining: $280.00 per part

- Setup: $50.00 per part

- Total: $450.00 per part

Key Learnings

This high-performance aerospace component illustrates the impact of expensive materials, tight tolerances, and complex geometry. Titanium’s poor machinability requires slower cutting speeds, significantly increasing machining time. The small production run amplifies setup costs.

Case Study 3: Medical PEEK Enclosure

Project Details

- Material: PEEK (Medical Grade)

- Size: 80×60×40mm

- Quantity: 50 pieces

- Tolerance: ±0.05mm

- Surface Finish: Biocompatible

Cost Breakdown

- Material: $35.00 per part

- Machining: $45.00 per part

- Setup: $5.00 per part

- Total: $85.00 per part

Key Learnings

This medical device component shows how specialized materials and quality requirements impact costs. PEEK is more expensive than standard plastics but offers superior biocompatibility. The moderate production run helps amortize setup costs effectively.

Cross-Case Analysis

| Factor | ABS Enclosure | Titanium Bracket | PEEK Enclosure |

|---|---|---|---|

| Material Cost | $2.50 (23%) | $120 (27%) | $35 (41%) |

| Machining Cost | $8.00 (73%) | $280 (62%) | $45 (53%) |

| Setup Cost | $0.50 (4%) | $50 (11%) | $5 (6%) |

| Total Cost | $11.00 | $450.00 | $85.00 |

| Cost Driver | Machining time | Material + Machining | Material cost |

Frequently Asked Questions

How accurate are these cost estimates?

These estimates are based on industry averages and our extensive experience. Actual costs can vary by ±15-20% depending on specific part geometry, material availability, and production location. For precise quotes, we recommend providing a detailed CAD model and specifications.

What’s the minimum order quantity for CNC machining?

Most CNC shops accept orders starting from 1 piece for prototyping. However, the economics of CNC machining improve significantly with larger quantities. For production runs, we recommend at least 10 pieces to make the most of setup costs. Some shops may have higher minimums for certain materials or processes.

How can I reduce CNC machining costs?

The most effective ways to reduce costs include: simplifying part geometry through DFM, choosing more cost-effective materials, optimizing production quantities, leveraging automation and AI programming, and working with experienced manufacturers who can provide design guidance.

How long does CNC machining take?

Lead times vary significantly based on part complexity and quantity: 1-3 days for simple prototypes, 3-7 days for small batches (11-100 pieces), 1-2 weeks for medium production (101-1,000 pieces), and 2-4 weeks for high volume production. Rush orders may be available for an additional fee.

What’s the difference between 3-axis, 4-axis, and 5-axis machining?

3-axis machines move in X, Y, and Z directions, suitable for simple parts. 4-axis adds rotation around one axis, enabling more complex geometries. 5-axis adds rotation around two axes, allowing machining of highly complex parts from all angles. More axes mean higher machine costs but can reduce setup time and improve part quality for complex components.

How do tolerances affect CNC machining costs?

Tighter tolerances significantly increase costs. Standard tolerances (±0.1mm) are the most economical. Precision tolerances (±0.01-0.05mm) can double or quadruple costs, while high precision (±0.001-0.01mm) can increase costs by 5-15 times. Always specify only the tolerances you truly need for functionality.

Conclusion & Recommendations

CNC machining costs are influenced by a complex interplay of factors, but with proper planning and optimization, significant savings can be achieved without compromising quality or performance.

Key Conclusions

- Machining time is the largest cost component (30-50%)

- Material selection has a 50x cost range

- Economies of scale reduce costs by 30-60%

- DFM optimization can save 20-40%

Actionable Recommendations

- Invest in DFM analysis early in the design process

- Choose materials based on actual performance requirements

- Plan production quantities strategically

- Work with experienced manufacturers for guidance

2026 Outlook

The CNC machining industry is evolving rapidly with several trends impacting costs:

- AI and automation will continue to reduce labor costs by 10-15% annually

- Material prices, especially for exotic alloys, are expected to remain volatile

- Sustainability requirements will add 5-10% to material and process costs

- 5-axis machining adoption will increase for complex parts, improving efficiency

Staying informed about these trends and working with forward-thinking manufacturers will be key to managing costs effectively in 2026 and beyond.

Optimize Your CNC Machining Costs with Goldcattle

With 26 years of experience and a data-driven approach to cost optimization, we help manufacturers reduce CNC machining costs by 20-40% while maintaining the highest quality standards.