Welcome to the world of CNC parts for industry. With the rapid development of manufacturing industry, CNC parts play an increasingly important role in the industrial field. As a professional CNC parts machining service provider, we are committed to providing customers with a full range of customized services, striving for perfection in every step from design to production. Below is our detailed introduction to help you better understand our services.

Customized Services

We understand that every project is unique, so we offer a full range of customized services. Customers can provide drawings or describe the specific requirements of the parts according to their needs. Our team of professional engineers will design and optimize the parts according to your needs, ensuring that each part is a perfect match for your equipment or system.

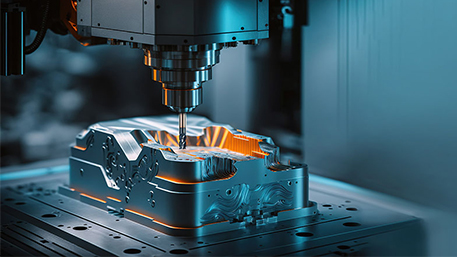

Processing Technology

We use advanced CNC machining technology, including CNC milling, CNC turning, laser cutting, wire cutting, etc., to ensure the machining precision and surface quality of the parts. At the same time, we are constantly introducing new technologies and processes to cope with increasingly complex machining needs.

Machining Equipment

Our factories are equipped with international advanced CNC machining equipment, including high-precision CNC lathes, milling machines, laser cutting machines and so on. These equipments not only improve the machining efficiency, but also ensure the consistency and reliability of the parts.

Machining Materials

We offer a wide range of material options, including stainless steel, aluminum alloy, titanium alloy, copper alloy, and plastic, to meet the needs of different industries and application scenarios. At the same time, we advise our customers on material selection based on the environment and requirements of the parts to ensure performance and longevity.

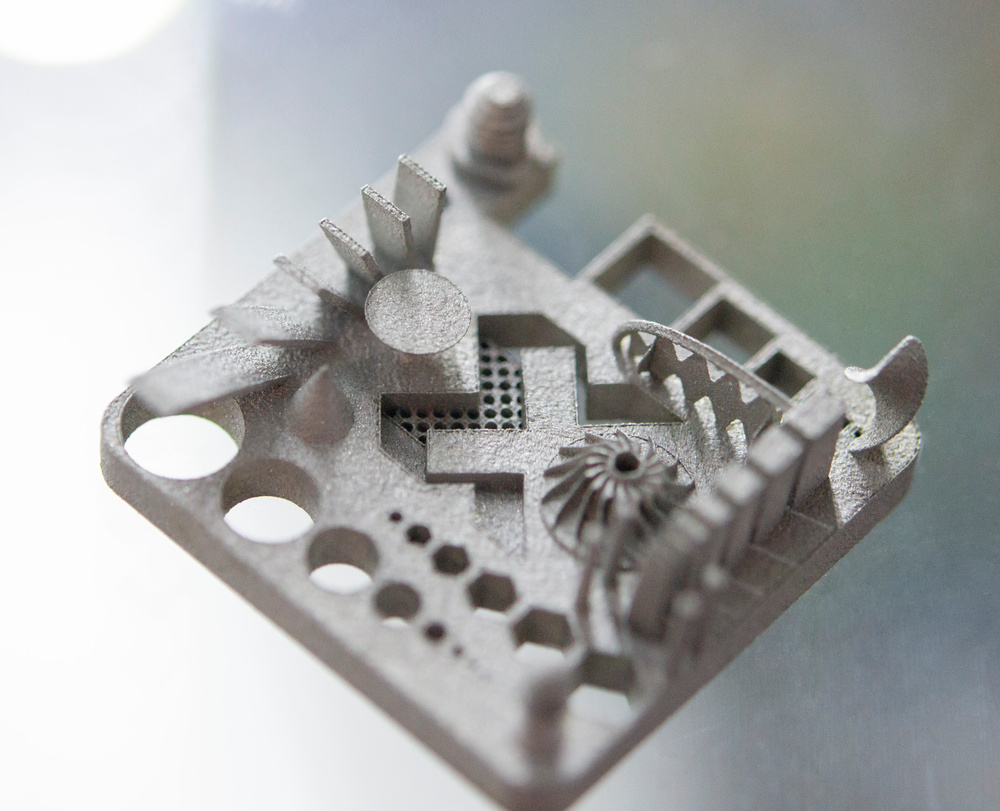

Products

Our products cover a wide range of industrial CNC parts, including shaft parts, gear parts, box parts, bracket parts and so on. These parts are widely used in machinery and equipment, automation equipment, aerospace, medical equipment and other fields.

Usage

Industrial CNC parts play a vital role in industrial production. They not only improve the performance and efficiency of the equipment, but also ensure the stability and reliability of the production line. Our parts are widely used in a variety of mechanical equipment and systems, such as automotive manufacturing, electronic equipment manufacturing, aerospace and other fields.

Shipment Cycle Time

We understand the importance of time in industrial projects. Therefore, we are committed to optimizing our production processes and shortening our lead times. Typically, our standard shipping lead time is 7-30 business days, depending on order complexity and quantity. For urgent orders, we provide expedited service to ensure that our customers receive the parts they need on time.

Quality Control

We have established a strict quality management system to conduct comprehensive quality inspection on each part. Each step, from incoming raw materials to finished products, is rigorously inspected to ensure that the parts meet customer requirements and industry standards. At the same time, we provide quality inspection reports and certificates of conformity so that customers can use them with confidence.

Questions and Answers

Q: What materials do you offer for CNC parts machining?

A: We offer a wide range of material choices, including stainless steel, aluminum alloy, titanium alloy, copper alloy, plastics, and more. The specific material selection needs to be determined according to the usage environment and requirements of the part.

Q: What is your machining accuracy?

A: We use advanced CNC machining technology and equipment to ensure that the machining accuracy of parts meets or exceeds industry standards. Meanwhile, we constantly introduce new technologies and techniques to improve machining accuracy and surface quality.

Q: How long is your shipping cycle?

A: Our standard shipping cycle is 7-30 working days, depending on the complexity and quantity of the order. For urgent orders, we provide expedited service to ensure that customers can receive the required parts on time.

Q: How do you perform quality control?

A: We have established a strict quality management system and conduct comprehensive quality inspection for each part. Each step, from incoming raw materials to finished products, is rigorously inspected to ensure that the parts meet customer requirements and industry standards. Meanwhile, we provide quality inspection reports and certificates of conformity.

Thank you for choosing our industrial CNC parts service! We look forward to working with you to promote the development of the manufacturing industry. If you have any questions or needs, please feel free to contact us.