What is the minimum bend radius for sheet metal parts?

The minimum bend radius (MBR) for sheet metal is the smallest inner radius achievable during bending without causing material cracking,

The minimum bend radius (MBR) for sheet metal is the smallest inner radius achievable during bending without causing material cracking,

The rule of thumb for sheet metal refers to practical design and processing guidelines accumulated from experience, simplifying complex engineering

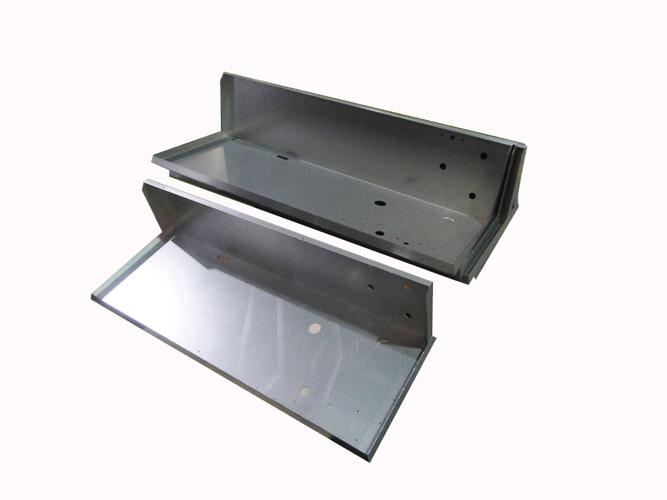

The five key sheet metal operations are shearing, bending, punching, drawing, and forming. Shearing cuts sheets to size; bending shapes

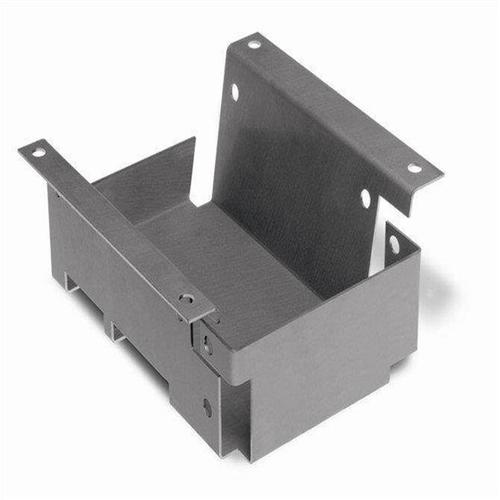

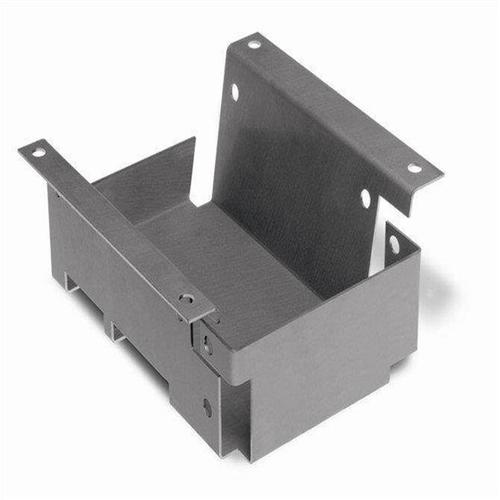

The core difference between sheet metal parts and machined parts lies in raw material form and processing methods: sheet metal

The 4T rule is a core guideline in sheet metal design to ensure bending accuracy, requiring functional features (e.g., holes,

Every machine, device, or structure you rely on—from your morning coffee maker to the jet that carries you across the

Every precision shaft, valve, or connector that powers our world starts with a machine designed for rotational excellence: the CNC

If you’ve ever wondered how smooth, symmetrical parts like shafts, bushings, or valve bodies are made, the answer lies in

Gone are the days of endless phone calls, delayed quotes, and unclear timelines for custom CNC parts. Today, ordering CNC

In the world of high-tech machinery, some of the most critical components are the smallest ones. Think of the tiny

From the valves that control industrial fluid flow to the surgical tools that save lives, countless critical components share two

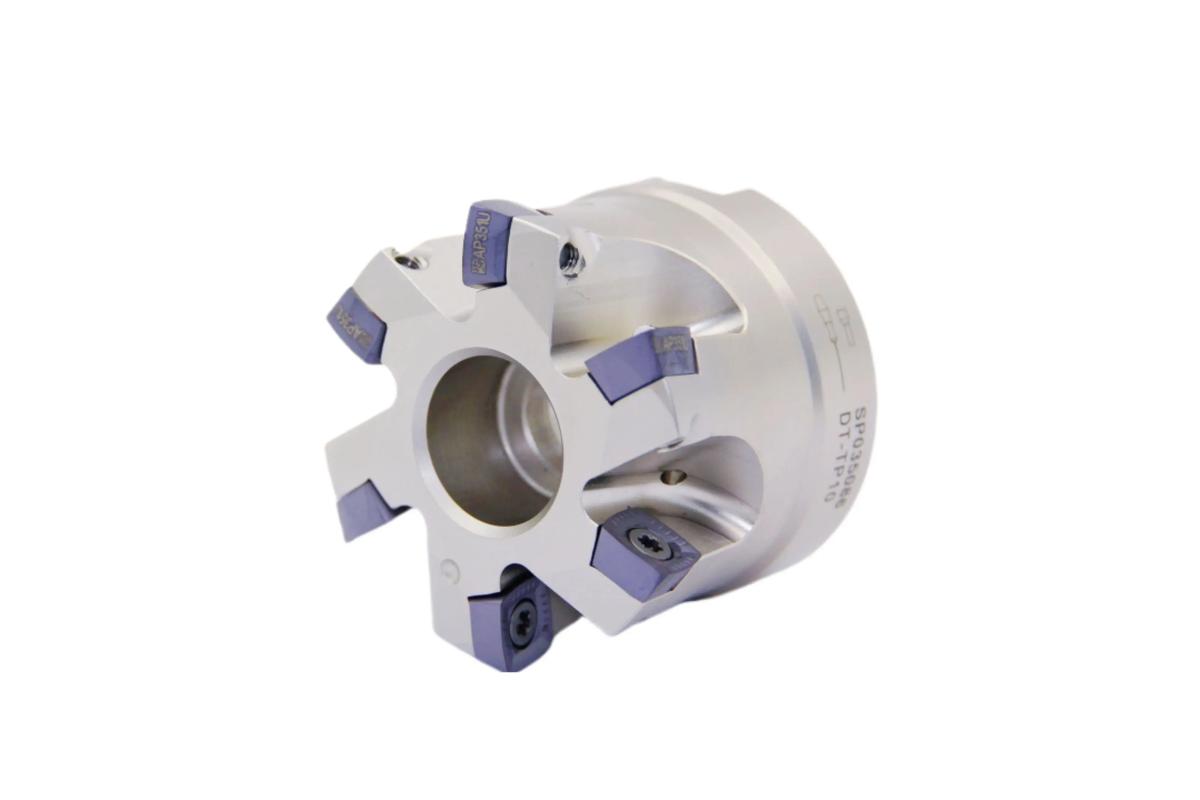

CNC milling is a subtractive manufacturing process where computer-controlled milling machines use rotating cutting tools to remove material from a