CNC Tool Collision Problem Solving Manual

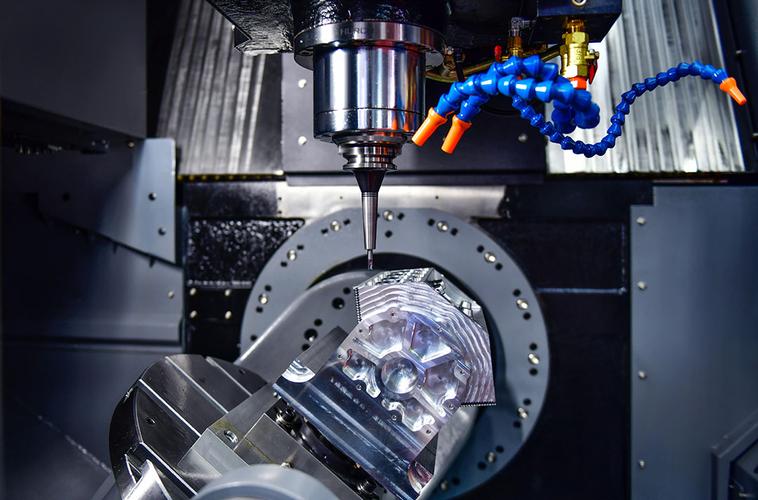

II. Tool Crash Types and Schematic Diagrams (Key Crash Points Marked) 1. Tool-Workpiece Crash (Most Frequent) Scenario: Excessive depth of

II. Tool Crash Types and Schematic Diagrams (Key Crash Points Marked) 1. Tool-Workpiece Crash (Most Frequent) Scenario: Excessive depth of

I. What is Workpiece Overcut? Overcut refers to a situation in CNC machining where the actual material removed by the

1. Preparation Before Alignment (Safety & Tools) 1.1 Equipment Safety Check Machine Zero Return: Execute G28 U0 W0 (for CNC lathes) or G28

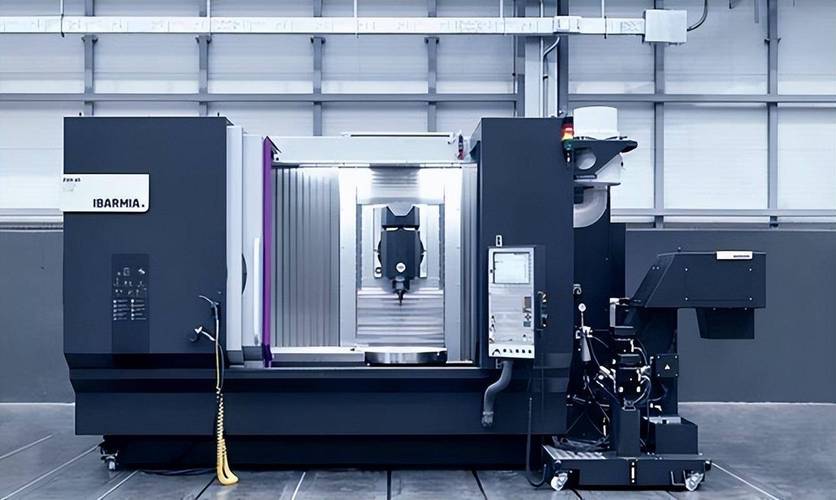

1. Preparations and Safety Specifications Equipment Status Check Execute G28 to return to the reference point and ensure the machine

Preface This manual is intended for product designers, makers, and small-to-medium enterprises. It details the full manufacturing process of CNC

I. Basic Understanding: Grasp the Essence of “CNC Prototype” in 3 Minutes Simply put, a CNC prototype is an “early product

Preface Medium-batch injection molding service is a critical link connecting “small-batch trial production” and “high-volume mass production”, focusing on production

Preface Micro Injection Molding is a precision molding technology developed for “miniaturized, high-precision, and highly complex” plastic parts. It enables

Preface This manual aims to systematically sort out common defect types in CNC machining processes, analyze the causes of various

Step into a precision machining workshop in modern manufacturing, and amid the intermittent hum of metal cutting, Computer Numerical Control

Custom stainless steel fittings—used in medical fluid systems, food processing pipelines, and industrial machinery—rely on the material’s unique combination of

Core Question: Why is Titanium Alloy the First Choice for Medical Parts? How to Balance Safety and Precision in Customization?