What are the steps in turning?

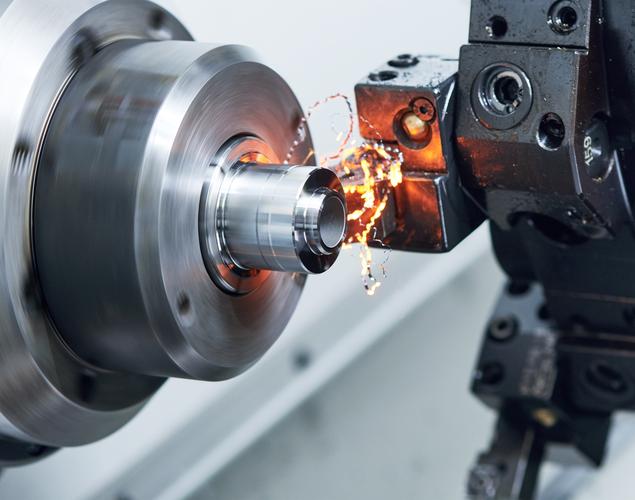

Answer: The main steps of turning include: Firstly, clamp the workpiece and the tool to ensure accurate positioning and firm

Answer: The main steps of turning include: Firstly, clamp the workpiece and the tool to ensure accurate positioning and firm

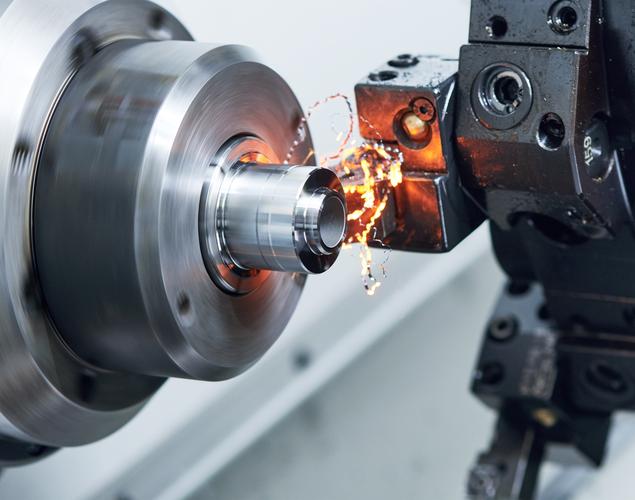

Answer: In turning, the workpiece rotates while the tool feeds, and it is used to process the outer diameter, inner

Answer: The parts processed by turning mainly include shaft – type parts (such as motor shafts, lead screws), disk –

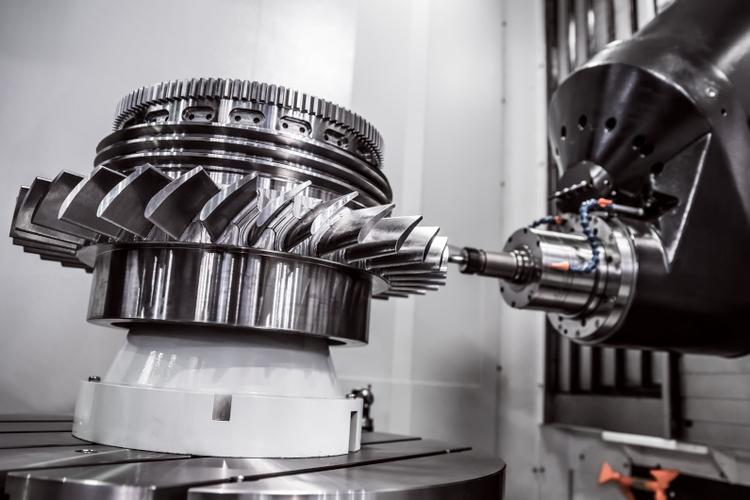

In the aerospace field, the performance and precision of components are directly related to the safety and reliability of aircraft.

In fields such as aerospace, medical devices, and high – end equipment manufacturing, titanium alloy has become an ideal material

Answer: There is no absolute answer as to whether milling or turning is more difficult. The difficulty of the two

Answer: Grinding and milling are two different processes in CNC machining. Their main differences lie in processing tools, machining accuracy,

Answer: In CNC machining, grinding is a processing method that uses a high – speed rotating grinding wheel and other

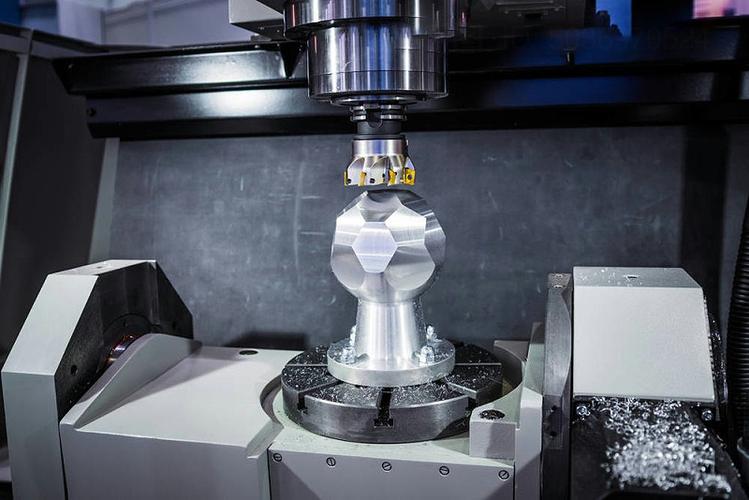

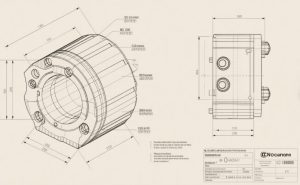

Answer: CNC machining, namely Computer Numerical Control machining, is mainly based on three key aspects: numerical control equipment, machining programs,

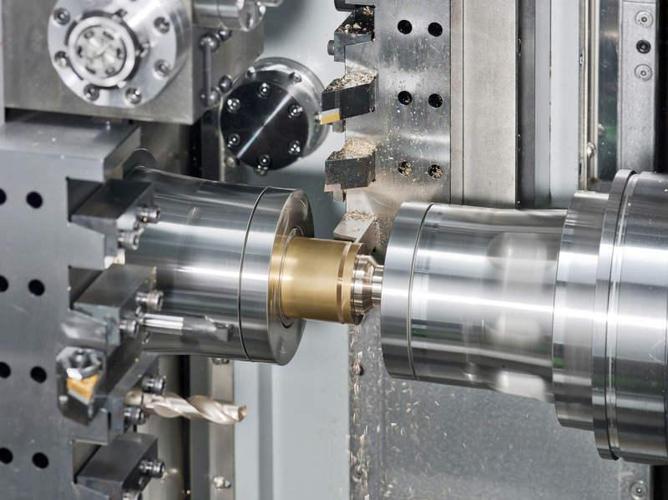

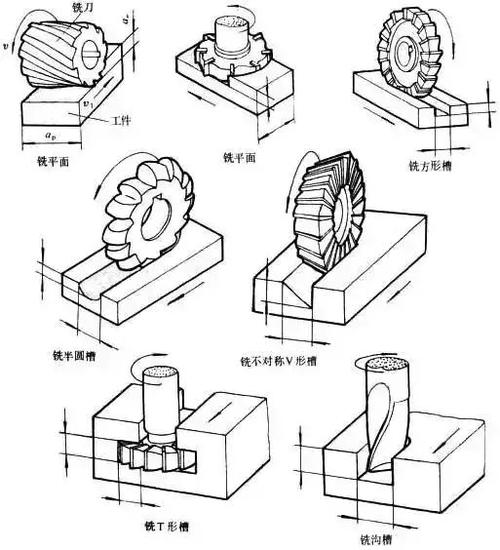

AnswerThe five core steps in the milling process usually include: programming and program preparation, workpiece clamping and positioning, tool setting

In the dynamic landscape of modern manufacturing, alloy steel CNC machining stands as a cornerstone technology, enabling the production of

In the intricate world of modern manufacturing, carbon steel CNC machining stands as a bedrock technology, enabling the production of