Exploring Injection Mold Machining Customization

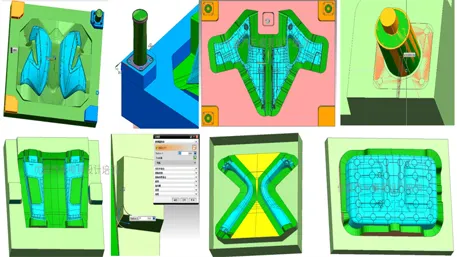

The children’s toy in your hand, the car dashboard, even the component casings of Mars rovers—they might all originate from the same “magic box”: the injection mold. Like a silent creator,…

The children’s toy in your hand, the car dashboard, even the component casings of Mars rovers—they might all originate from the same “magic box”: the injection mold. Like a silent creator,…

Imagine, in today’s era of rapid technological development, how does every precision instrument and every delicate part around us transform from a common material into a perfect finished product? The…

Ⅰ. Why Plastics Became the Automotive Industry’s New Darling Traditional steel-dominated automotive manufacturing has seen a paradigm shift since the 1990s, with plastics now accounting for 12-15% of a vehicle’s total…

I. Why Has Customized Plastic Parts Become a “Must-have Option” in the Manufacturing Industry? Market Explosion: The Real Demand Behind the Data According to the 2025 industry report, the global market size…

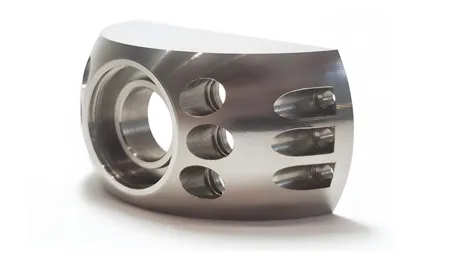

1. DNA of Precision: From Punched Cards to AI-Driven Machining The CNC revolution began in 1952 with MIT’s servomotor-controlled milling machine, but its true breakthrough came with microprocessor integration in 1974. Modern 5-axis…

1. Material Anisotropy & Toolpath Psychology CNC machining navigates material “personality” through adaptive algorithms. For aluminum alloys (e.g., 6061-T6), grain directionality causes 12-18% variance in surface roughness when cutting parallel vs. perpendicular…

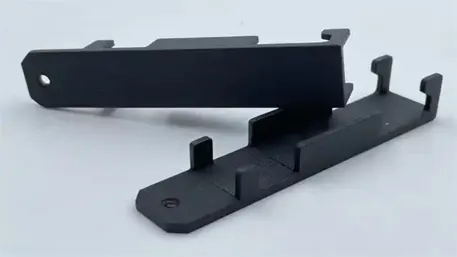

1. Technical Advantages Beyond Conventional Machining 5-Axis Supremacy: Modern CNC systems achieve ±0.005mm positioning accuracy on complex geometries (e.g., drone frames with 15° undercut angles) through synchronized A/B-axis rotations. Material Versatility: From aerospace-grade…

1. The Anatomy of Modern CNC Machines Modern CNC systems integrate 4 key subsystems for precision manufacturing: Controller Unit: Converts CAD files into machine-readable G-code, with advanced systems supporting real-time error correction Drive…

1. Cost Variance Influencing Factors The cost disparity between CNC machining and forging stems from multiple technical and operational variables: Material Utilization: Forging achieves 85-95% material efficiency by reshaping billets , while…

I. Target Audience: Custom CNC Injection Mold Seekers Designed for engineers and procurement specialists in: Medical Device Startups (ISO 13485-compliant microfluidic chips) Automotive Tier 1 Suppliers (multi-material connectors, tolerance ≤±0.02mm) Consumer Electronics…