I. Market Size and Growth Trends

1.1 Overall Size

In 2024, the global injection – molded plastics market reached a size of $335.4 billion. Looking at historical data, the market has shown a steady upward trend over the past few years, reflecting the wide application of injection – molded plastics in various industries and the continuous growth of demand. It is expected that by 2030, the market size will increase to $439.4 billion, with a compound annual growth rate (CAGR) of 4.6% from 2024 to 2030. This growth trend is driven by the demand for injection – molded plastic products in multiple industries, as well as the expansion of new application areas brought about by technological development.

1.2 Sub – market Sizes

By Raw Material: The polypropylene (PP) raw material segment holds an important position in the market. It already had a large scale in 2024 and is expected to reach $162.4 billion by 2030. Due to its good comprehensive properties, such as chemical resistance, high strength, and easy processability, PP is widely used in automotive parts, packaging, home appliances, and other fields. Other raw materials such as acrylonitrile – butadiene – styrene copolymer (ABS), high – density polyethylene (HDPE), polystyrene (PS), etc., also have a certain market share in their respective sub – application scenarios. By Region: In 2024, the injection – molded plastics market in the United States was $87.9 billion. As a highly industrialized country, its automotive, electronics, electrical appliances, medical, and other industries have a huge demand for injection – molded plastic products. The Chinese market has great potential. With a certain scale base in 2024, it is expected to reach $95.2 billion by 2030, with an annual growth rate of about 7%. The rapid development of China’s manufacturing industry, especially the expansion in the automotive, home appliance, and packaging fields, has greatly promoted the growth of the injection – molded plastics market. In addition, regions such as Asia – Pacific (excluding China) and Europe also occupy important shares in the global injection – molded plastics market. Due to differences in industrial structure and economic development levels, the market sizes and growth rates of different regions vary.

II. Technical Development Analysis

2.1 Innovation in Injection – molding Machinery Technology

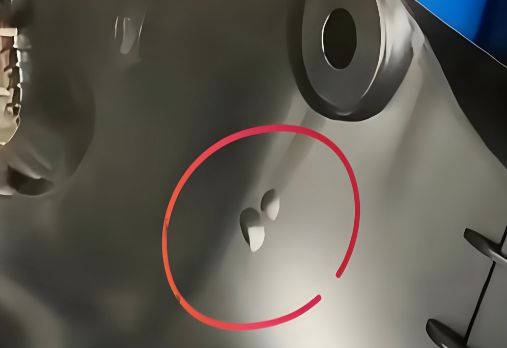

Modern injection – molding machinery continuously introduces advanced technologies to improve production efficiency and product quality. For example, new – type injection – molding machines adopt more precise control systems, which can accurately control parameters such as pressure, temperature, and speed during the injection – molding process, thereby reducing product defects and increasing the yield rate. Some high – end injection – molding machines are equipped with intelligent sensors that can monitor the operating status of the equipment in real – time, predict potential failures, and issue timely warnings, reducing equipment downtime. In terms of mechanical structure, the optimized design of the clamping system and injection system improves the stability and response speed of the equipment, making the injection – molding process more efficient and precise.

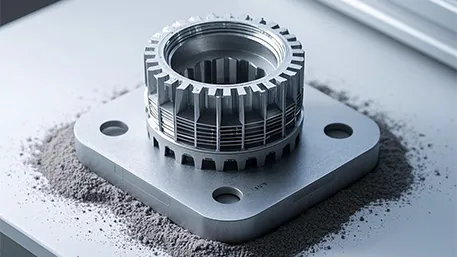

2.2 Integration of 3D Printing and Injection – molding Technology

The integration of 3D printing technology and traditional injection – molding technology has brought new development opportunities to the injection – molded plastics industry. 3D printing can quickly manufacture prototypes of injection – molding molds, greatly shortening the mold development cycle and reducing development costs. For some small – batch, customized injection – molded products, 3D printing can directly produce the final products, avoiding the high costs of traditional injection – molding mold manufacturing. In addition, by manufacturing injection – molding mold inserts with complex internal structures through 3D printing, lightweight design of injection – molded products can be achieved while improving product performance. This integration of technologies expands the design space and application scope of injection – molded plastic products, meeting the market demand for personalized and high – performance products.

2.3 Technologies Related to Sustainable Development

With the enhancement of environmental awareness and the popularization of the concept of sustainable development, the injection – molded plastics industry is actively researching and applying related technologies. The application of biodegradable plastics in the injection – molding field is gradually increasing. By means of biodegradation or photodegradation, the impact of plastic waste on the environment is reduced. Some enterprises use recycled plastics as raw materials for injection – molding production, which not only reduces the dependence on new raw materials but also realizes the recycling of resources. During the production process, energy – saving technologies and equipment, such as efficient heating systems and intelligent energy management systems, are adopted to reduce energy consumption and carbon emissions. The application of these sustainable development technologies meets the market demand for green products and helps enterprises enhance their competitiveness.

III. Factors Affecting Market Demand

3.1 Demand from Major Application Industries

Automotive Industry: The automotive industry is an important application field of injection – molded plastics. To achieve vehicle lightweighting to improve fuel efficiency and reduce exhaust emissions, automakers are increasingly using injection – molded plastic products to replace traditional metal parts. Injection – molded plastics are widely used in automotive interiors (such as instrument panels, seat armrests, door panels, etc.), exteriors (such as bumpers, rear – view mirror housings, grilles, etc.), and numerous components in the engine compartment. With the stable growth of global automobile production and the rapid development of new energy vehicles, the demand for injection – molded plastics continues to rise.

Packaging Industry: The packaging industry has a huge demand for injection – molded plastics. Injection – molded plastic products have good formability, barrier properties, and appearance performance, and are widely used in food packaging, beverage packaging, cosmetic packaging, and pharmaceutical packaging. Injection – molded products such as plastic containers, bottle caps, and packaging boxes can effectively protect products, extend the shelf – life, and meet consumers’ demands for beautiful and convenient packaging. With the rise of the e – commerce industry and the continuous expansion of the consumer market, the demand for injection – molded plastics in the packaging industry remains steadily growing.

Packaging Industry: The packaging industry has a huge demand for injection – molded plastics. Injection – molded plastic products have good formability, barrier properties, and appearance performance, and are widely used in food packaging, beverage packaging, cosmetic packaging, and pharmaceutical packaging. Injection – molded products such as plastic containers, bottle caps, and packaging boxes can effectively protect products, extend the shelf – life, and meet consumers’ demands for beautiful and convenient packaging. With the rise of the e – commerce industry and the continuous expansion of the consumer market, the demand for injection – molded plastics in the packaging industry remains steadily growing.

3.2 Opportunities in Emerging Markets

The rapid economic development and acceleration of the industrialization process in emerging market countries have brought new opportunities to the injection – molded plastics market. In some emerging economies in Asia, Africa, and Latin America, infrastructure construction, the development of the manufacturing industry, and the expansion of the consumer market have driven the demand for injection – molded plastic products. For example, the construction industry in these regions has an increasing demand for injection – molded products such as plastic pipes and fittings; the development of the electronics and electrical appliances industry has driven the demand for plastic shells and components; and the upgrading of the consumer market has led to an increase in the demand for various injection – molded packaging and home appliances. The large population base and the continuously improving living standards in emerging markets make them an important driving force for the growth of the global injection – molded plastics market.

3.3 Dependence of the Medical Equipment Industry

The medical equipment industry has a high degree of dependence on injection – molded plastics. Injection – molded plastics have good biocompatibility, chemical resistance, and processing performance, and can be used to manufacture various medical equipment components, such as syringes, infusion sets, medical device shells, and prosthetic components. With the intensification of the global aging population, the progress of medical technology, and the increase in the demand for healthcare services, the demand for injection – molded plastics in the medical equipment industry shows a steady growth trend. At the same time, the strict requirements for the quality and safety of medical products have prompted injection – molded plastic manufacturers to continuously improve product quality and technical levels to meet the special needs of the medical equipment industry.

IV. Driving Factors for Market Growth

4.1 Promotion by Technological Innovation

Technological innovation is one of the core driving forces for the growth of the injection – molded plastics market. As mentioned above, the improvement of injection – molding machinery technology, the integration of 3D printing and injection – molding technology, and the application of sustainable development technologies have all brought new opportunities to the industry. The application of new technologies improves production efficiency, reduces production costs, and expands the application fields of products, thus stimulating market demand. For example, a more efficient injection – molding process can achieve a faster production cycle, enabling enterprises to meet the market’s demand for product quantity; new materials and manufacturing technologies enable injection – molded products to have better performance, such as higher strength, wear resistance, and corrosion resistance, meeting the needs of high – end application fields and further promoting market growth.

4.2 Improvement of Consumers’ Quality Requirements

With the improvement of consumers’ living standards and the change of consumption concepts, the quality requirements for plastic products are increasingly rising. Consumers pay more attention to the safety, durability, and aesthetics of products. Injection – molded plastic manufacturers continuously improve production processes, use higher – quality raw materials, and enhance product quality and appearance to meet consumers’ needs. For example, in the food packaging field, consumers have extremely high requirements for the hygiene and safety of packaging materials. Enterprises ensure product quality by using injection – molded plastic raw materials that meet food – contact standards and optimizing hygiene control measures in the production process. This change in consumer demand prompts enterprises to increase R & D investment, promotes the development of the entire injection – molded plastics market towards high – quality products, and thus drives the growth of the market size.

4.3 Increase in Investment in Sustainable Materials

Sustainable development has become a global consensus, and the injection – molded plastics industry is no exception. To address environmental challenges, enterprises and investors have increased their investment in the research, development, and production of sustainable materials. The market share of sustainable injection – molded materials such as biodegradable plastics and recycled plastics is gradually expanding. On the one hand, the government has introduced a series of environmental protection policies and regulations to encourage enterprises to use sustainable materials, which has promoted market demand. On the other hand, consumers’ recognition of environmentally friendly products is constantly increasing, and they are willing to pay a higher price for sustainable injection – molded plastic products. The dual role of market demand and policy orientation prompts enterprises to increase investment in sustainable materials, promote the development and application of related technologies, and thus drive the growth of the injection – molded plastics market.

V. Analysis of the Competitive Landscape

5.1 Overview of Major Enterprises

The injection – molded plastics market is highly competitive, with numerous domestic and foreign enterprises. Enterprises such as Alcoa, Amaray, and Xiamen Goldcattle are influential in the industry. Xiamen Goldcattle has strong strength in material research, development, and production. Its products are widely used in high – end fields such as automotive and aerospace, and it occupies a place in the market with high – quality products and advanced technologies. Some enterprises focus on the production of injection – molded plastic products and have won market share with their innovative packaging solutions and good customer service. In addition, other enterprises are also actively deploying in the injection – molded plastics market. With a rich product line, strong R & D capabilities, and a wide sales network, they are in a leading position in market competition.

5.2 Enterprise Competitive Strategies

Product Innovation: Enterprises continuously develop new products and improve existing products to meet the diverse needs of the market. For example, they develop injection – molded plastics with special properties, such as high – strength, high – temperature – resistant, and ultraviolet – resistant products, to meet the needs of specific industries such as automotive, electronics, electrical appliances, and outdoor products. At the same time, they pay attention to product appearance design and personalized customization to increase product added value.

Cost Control: Measures are taken to reduce costs in raw material procurement, production process optimization, equipment renewal, etc. By establishing long – term and stable cooperative relationships with suppliers, more favorable purchase prices can be obtained; by optimizing the production process, production efficiency can be improved, energy consumption and rejection rates can be reduced; and by investing in advanced equipment, labor costs and equipment maintenance costs can be reduced. Cost advantages help enterprises maintain price competitiveness in the market.

Market Expansion: Actively explore domestic and foreign markets, especially emerging markets. By setting up sales offices, establishing production bases, and cooperating with local enterprises, enterprises can deeply understand local market demands, respond quickly to customer orders, and increase market share. At the same time, strengthen brand building and marketing activities to enhance brand awareness and reputation.

Cost Control: Measures are taken to reduce costs in raw material procurement, production process optimization, equipment renewal, etc. By establishing long – term and stable cooperative relationships with suppliers, more favorable purchase prices can be obtained; by optimizing the production process, production efficiency can be improved, energy consumption and rejection rates can be reduced; and by investing in advanced equipment, labor costs and equipment maintenance costs can be reduced. Cost advantages help enterprises maintain price competitiveness in the market.

Market Expansion: Actively explore domestic and foreign markets, especially emerging markets. By setting up sales offices, establishing production bases, and cooperating with local enterprises, enterprises can deeply understand local market demands, respond quickly to customer orders, and increase market share. At the same time, strengthen brand building and marketing activities to enhance brand awareness and reputation.

VI. Conclusion and Outlook

6.1 Conclusion

The global injection – molded plastics market is expected to maintain stable growth from 2024 to 2030. The market size will increase from $335.4 billion to $439.4 billion, with a CAGR of 4.6%. Technological development continues to drive industry changes. The improvement of injection – molding machinery technology, the integration of 3D printing and injection – molding technology, and the application of sustainable development technologies have become important trends. The demand from industries such as automotive, packaging, and medical equipment is the main driving force for market growth, and the rise of emerging markets also brings new opportunities to the industry. In terms of the competitive landscape, numerous enterprises compete for market share through strategies such as product innovation, cost control, and market expansion.

6.2 Outlook

In the future, the injection – molded plastics market will continue to be driven by technological innovation and changes in market demand. With the continuous progress of science and technology, it is expected that more advanced injection – molding technologies and materials will emerge, further improving production efficiency and product performance and expanding application fields. Sustainable development will be a key direction for the industry’s development. The application of biodegradable plastics and recycled plastics will become more widespread, and enterprises need to increase investment in the research, development, and production of environmental protection technologies. In terms of market demand, emerging markets have huge growth potential, and at the same time, consumers’ requirements for product quality and environmental performance will continue to increase. Enterprises should pay close attention to market dynamics, strengthen technological innovation and product research and development, optimize production processes, and actively expand the market to adapt to market changes and gain a competitive advantage in the fierce competition.