Simple and Practical Tips for Successful Plastic Part Design

1. Wall Thickness Design

Wall thickness is one of the most important design considerations.

Keep it uniform

- All parts of your design should have similar thickness

- This prevents problems like warping and sink marks

Avoid extremes

- Too thin: Material can’t flow properly

- Too thick: Causes long cooling times and defects

Recommended thickness range

- Most plastics: 0.04 to 0.15 inches (1 to 3.8 mm)

- Check specific material recommendations

2. Draft Angles

Draft angles help parts release from the mold easily.

What is draft?

- A slight taper on vertical surfaces

- Like a cone shape instead of a cylinder

How much draft do you need?

- Minimum: 1 degree per inch of depth

- Textured surfaces: 2-3 degrees

- Deep cavities: More draft is better

Why it’s important

- Prevents parts from sticking in the mold

- Reduces damage to parts during ejection

3. Corner Radii

Sharp corners cause problems in injection molding.

Replace sharp corners with radii

- Internal corners: Radius = 0.5 × wall thickness

- External corners: Radius = 1.5 × wall thickness

Benefits of radii

- Reduces stress concentrations

- Prevents cracks and breakage

What happens with sharp corners?

- Material can’t flow smoothly

- Creates weak points in the part

- Causes stress risers

4. Rib Design

Ribs add strength without increasing wall thickness.

Proper rib dimensions

- Rib thickness = 0.6 × wall thickness

- Rib height = 3-4 × wall thickness

- Space between ribs = 2 × wall thickness

Design tips

- Taper rib sides for easier ejection

- Avoid thick sections at rib intersections

Advantages

- Increases stiffness and strength

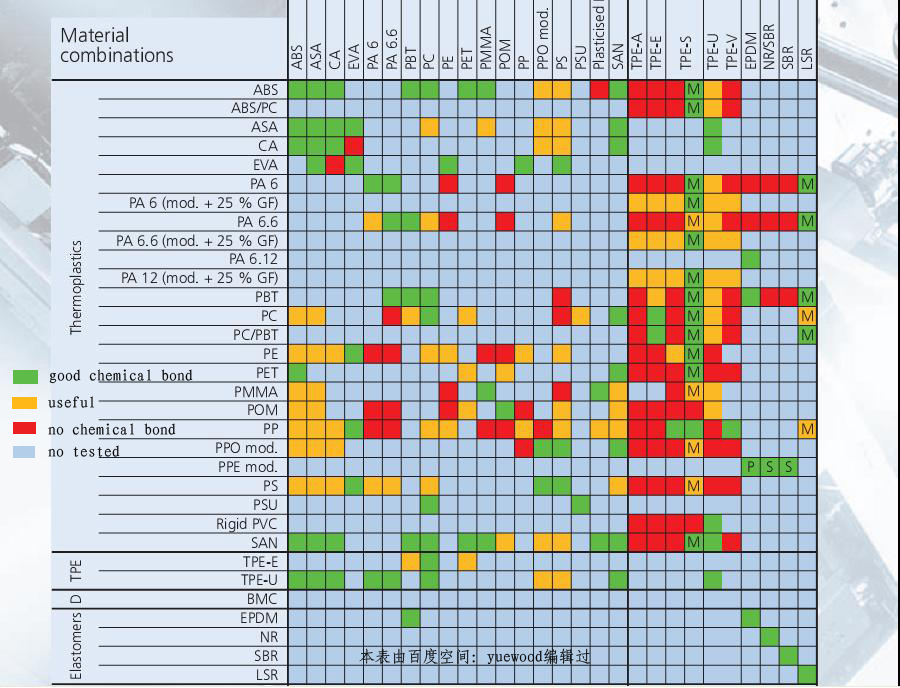

5. Material Selection

Choosing the right material is crucial.

Common materials

- ABS: Strong, impact resistant, good for housings

- Polypropylene: Flexible, chemical resistant, low cost

- Polycarbonate: Transparent, high impact strength

- Nylon: Tough, wear resistant, good for gears

- Acrylic: Clear, scratch resistant, good optics

Selection factors

6. Shrinkage Considerations

All plastics shrink when cooled.

Understanding shrinkage

- Different materials shrink different amounts

- Typical range: 0.5% to 2.5%

- Semi-crystalline plastics shrink more than amorphous

Design compensation

- Scale your design larger to account for shrinkage

- Consult material data sheets for specific values

- Consider directional shrinkage effects

Avoiding problems

- Uniform wall thickness reduces uneven shrinkage

- Proper cooling minimizes warping

- Adequate draft helps with shrinkage issues

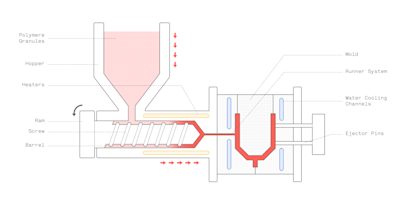

7. Gate Design

Gates control how material enters the mold.

Common gate types

- Edge gate: Simple, economical, good for most parts

- Pin gate: Small, leaves minimal 痕迹,good for cosmetics

- Submarine gate: Hidden, automatic trimming

- Hot runner gate: For high volume production

Gate placement

- Position at thickest section

- Avoid flowing against cores

- Consider cosmetic requirements

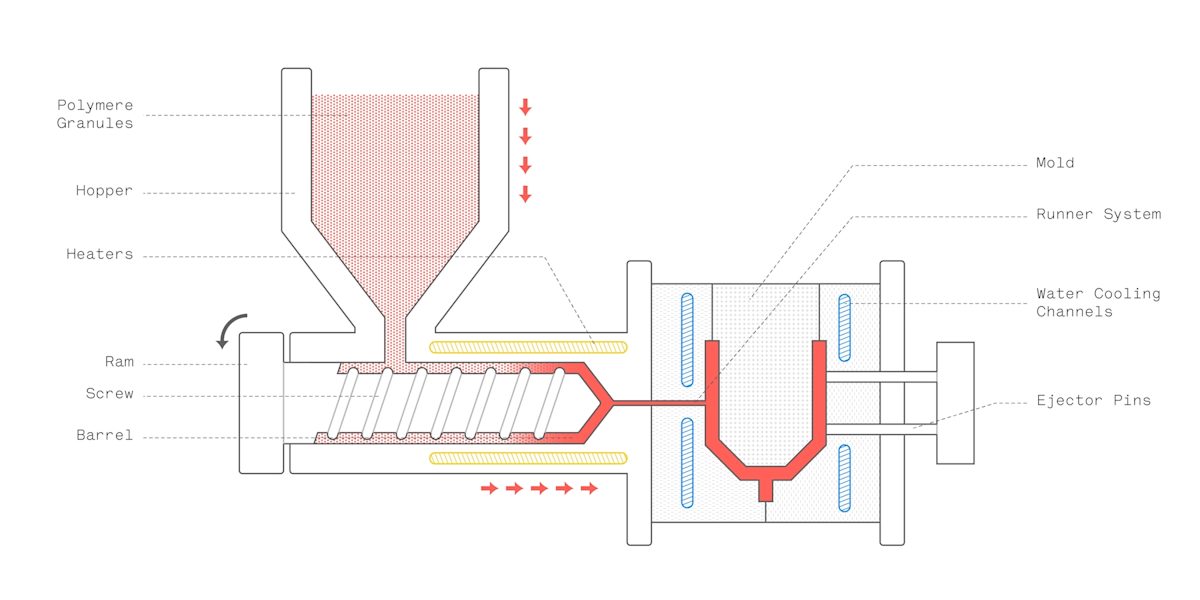

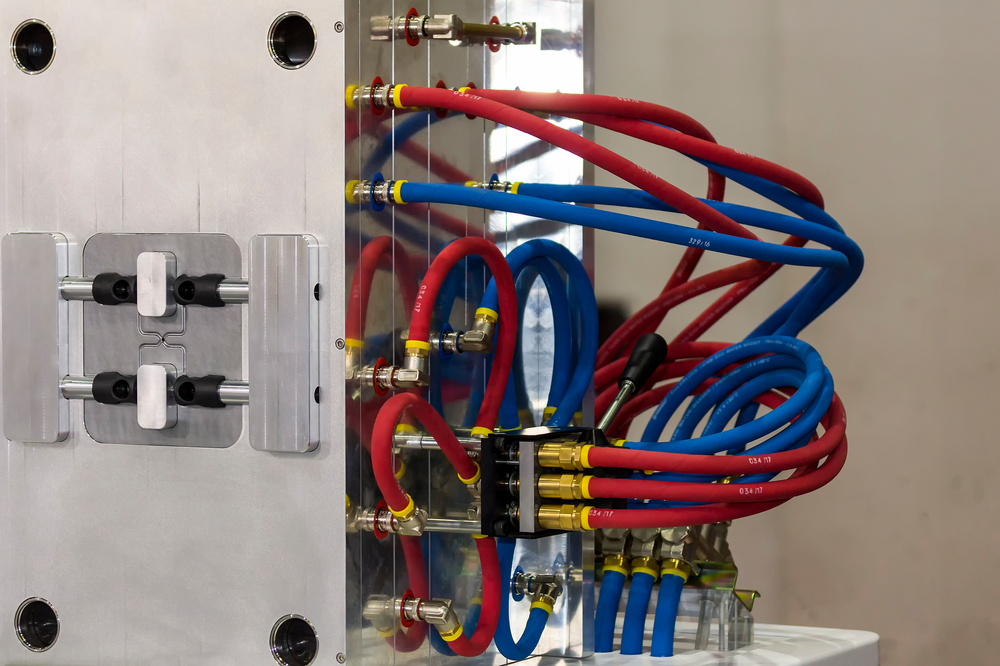

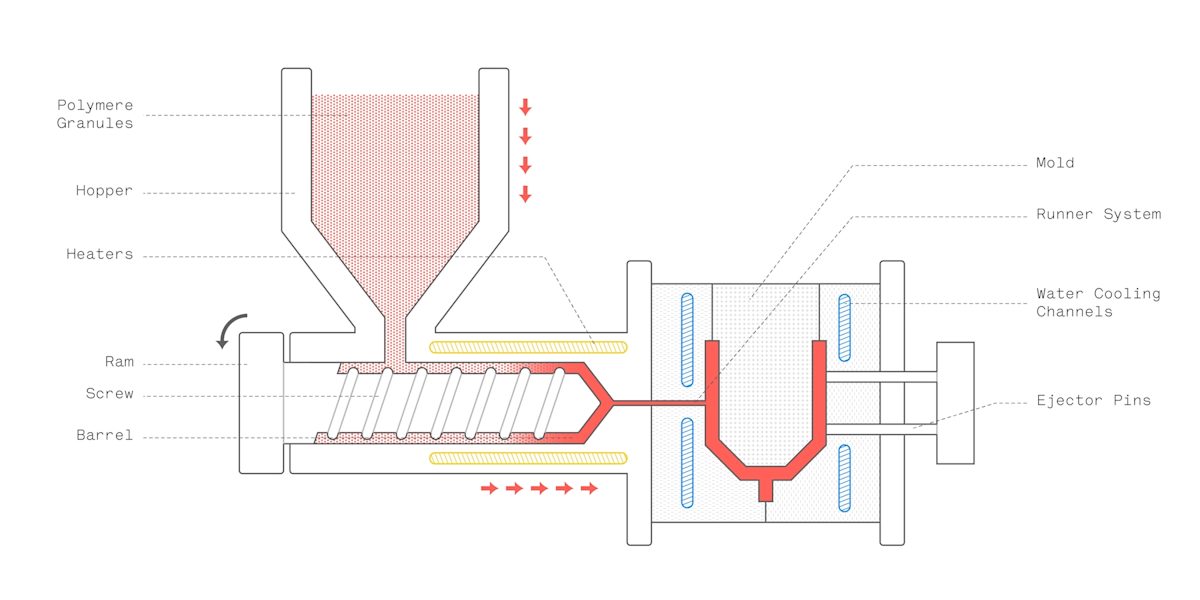

8. Cooling System Design

Proper cooling improves quality and reduces cycle time.

Design principles

- Cool uniformly across the part

- Cooling channels should be 1-2 × diameter apart

- Channel diameter = 0.125-0.5 inches

- Maintain 0.1-0.2 inch distance from cavity surface

Cooling types

- Water cooling: Most common, efficient

- Oil cooling: For high temperature materials

- Baffle cooling: For deep cavities

- Sprue cooling: For large gates

Benefits

- Improves part dimensional stability

- Minimizes warping and distortion

- Increases production efficiency

9. Tolerance Design

Specify realistic tolerances.

Standard tolerances

- SPI mold classes: SPI 1 (tightest) to SPI 5 (loosest)

- Typical tolerance: ±0.002-0.005 inches per inch

- Smaller parts: Tighter tolerances possible

Tolerance factors

- Material type affects achievable tolerance

- Part size: Larger parts have larger tolerances

- Feature location: Tolerances increase with distance

- Surface finish requirements

Cost considerations

- Tighter tolerances increase mold cost

- Only specify tight tolerances where needed

- Consider assembly requirements

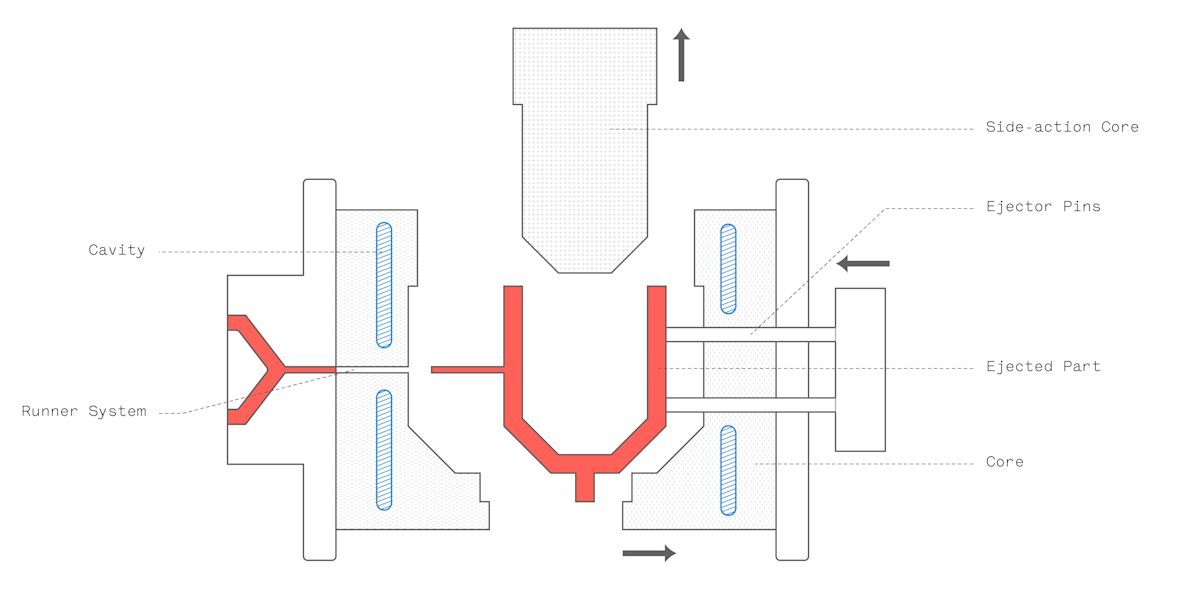

10. Undercut Avoidance

Undercuts complicate mold design and increase cost.

What is an undercut?

- A feature that prevents straight ejection

- Examples: Threads, hooks, recesses

Design alternatives

- Use snap fits instead of threads

- Design parts to assemble after molding

- Use living hinges for flexible features

- Consider side actions if undercuts are necessary

When undercuts are needed

- Use side pulls or lifters

- Consider unscrewing mechanisms

- Be prepared for higher mold costs

11. Mold Feasibility

Design parts that can be molded efficiently.

Mold structure considerations

- Avoid thin steel sections in molds

- Ensure adequate mold strength

- Consider mold cooling requirements

- Plan for easy maintenance

Parting line design

- Place parting lines where they won’t affect appearance

- Avoid complex parting lines when possible

- Consider flash removal requirements

Ejection system

- Design for balanced ejection

- Place ejector pins in non-critical areas

- Consider part ejection forces

12. Cost Considerations

Design for cost-effective production.

Material costs

- Use standard materials when possible

- Consider material availability

Mold costs

- Simple designs cost less to tool

- Consider production volume when designing

Production costs

- Design for fast cycle times

- Minimize post-processing requirements

- Consider automation potential

Total cost factors

- Initial tooling cost vs. production volume

- Labor and processing costs

- Quality and scrap rates

Design Checklist

Before finalizing your design:

✓ Check wall thickness uniformity

✓ Add proper draft angles

✓ Replace sharp corners with radii

✓ Design ribs correctly

✓ Select appropriate material

✓ Account for shrinkage

✓ Choose proper gate location

✓ Plan cooling system

✓ Specify realistic tolerances

✓ Avoid unnecessary undercuts

✓ Ensure mold feasibility

✓ Consider total costs

Common Design Mistakes

Avoid these common pitfalls:

❌ Uneven wall thickness

❌ Insufficient draft angles

❌ Sharp corners without radii

❌ Overly thick ribs

❌ Ignoring material shrinkage

❌ Poor gate placement

❌ Inadequate cooling design

❌ Unrealistic tolerances

❌ Unnecessary undercuts

❌ Complex mold requirements

❌ Overlooking production costs

Material Color Selection

Choosing the right color is important for product appearance.

Color matching

- Use Pantone or RAL color standards

- Consider material transparency

- Test colors under different lighting conditions

Color stability

- Some colors fade in sunlight

- Consider outdoor exposure requirements

- Check material compatibility with colorants

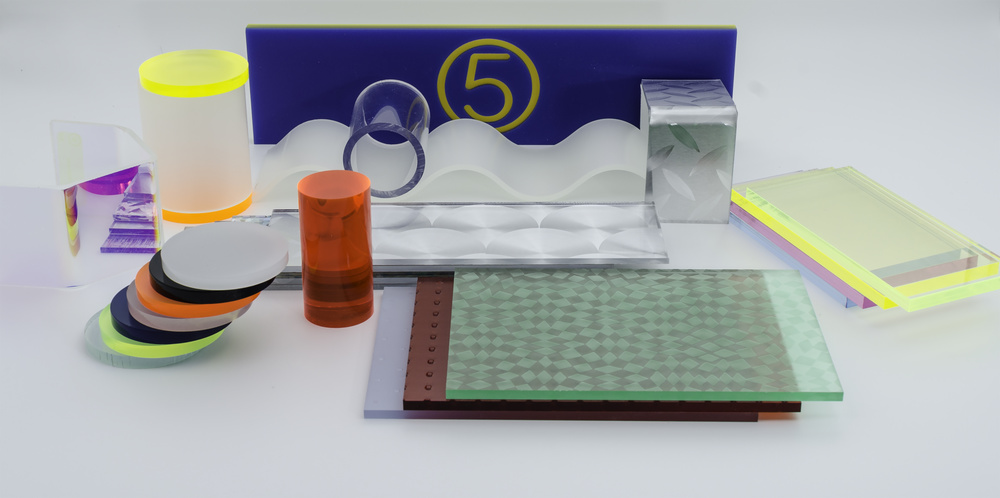

Plastic Material Samples

Visual reference of common plastic materials.

Material characteristics

Sample testing

- Test mechanical properties

- Evaluate chemical resistance

- Check dimensional stability

This guide provides general design principles for injection molding. Always consult with experienced mold designers and manufacturers for specific applications and requirements.