1. Technical Principle: The High-Tech Version of Steaming Buns

Injection molding works like a “plastic chef” cooking raw materials. Plastic pellets are heated to 200-300°C until molten, then injected into molds under high pressure. Modern machines use intelligent sensors to monitor temperature fluctuations within ±0.5°C, akin to a precision oven. Example: In automotive headlight production, mold pressure monitoring reduces product deformation from 3% to 0.8%.

2. Cost Analysis: Three Keys to Savings

| Item | Traditional Method | Optimized Solution (Annual 100k units) | Annual Savings |

|---|---|---|---|

| Mold Cooling | Standard steel mold | Conformal cooling channels | $14,000 |

| Material Waste | Direct disposal | Regrinding recycled sprues | $10,500 |

| Quality Control | Manual inspection | AI vision system | $26,000 |

Case Study: A Shenzhen factory reduced machine downtime from 12% to 3% through staff training, saving $40,000 annually.

3. Product Features: The Transformers of Plastics

- Strength: Glass-fiber reinforced nylon withstands 150°C (like car engine parts)

- Precision: ±0.02mm tolerance for smartphone SIM trays (1/3 hair thickness)

- Specialty: Antibacterial plastics eliminate 99% of surface bacteria

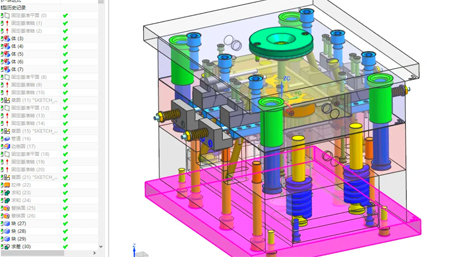

4. Production Workflow: Birth of a Phone Case

- Design Validation: 3D modeling with 1-2° draft angles to prevent sticking

- Trial Molding: 50 test samples to adjust gate positions

- Mass Production Prep: Mold preheated to 80°C, barrel zones controlled

- Molding: 120-ton clamping force (≈10 sedans’ weight)

- Post-Processing: Regrind sprues to save 15% material

- QC: CMM (Coordinate Measuring Machine) checks critical dimensions

5. Customization: From Blueprint to Product

Service Flow:

Customer Requirements → DFM Analysis → 3D Prototyping → Small-Batch Trial → Mass Production

Common Design Fixes:

- Wall thickness variation → Add ribs

- Insufficient draft angle → Increase by 0.5-1°

- Poor gate location → Mold flow analysis

6. Core Advantages: Unmatched by Alternatives

| Process | Unit Cost | Daily Output | Surface Finish |

|---|---|---|---|

| Injection Molding | $0.40 | 8,000 | Ra0.8μm |

| CNC Machining | $6.80 | 150 | Ra1.6μm |

| 3D Printing | $5.20 | 300 | Ra3.2μm |

Efficiency: One mold produces 8,000 parts/day (fills two trucks).

7. Applications: Ubiquitous in Daily Life

- Electronics: TWS earphone housings with 99.8% yield

- Medical: 50M insulin syringes/year using medical-grade PC

- Automotive: Door handle molds lasting 500k cycles (100k cars)

- Novelties: Custom guitar picks selling 200k/month

Pro Tips: Industry Insider Knowledge

- Mold Life: 100k-300k cycles (ignore “lifetime warranty” claims)

- Contract Clauses: Specify “all surface treatments included” to avoid hidden fees

- Material Testing: Keep samples from every batch to prevent fraud

Q&A Section

Q: How to evaluate mold quality?

A: Check three factors:

- Core hardness ≥HRC52

- Mold frame brands (e.g., DME/HASCO)

- Trial molding videos

Q: Fix flow marks on surfaces?

A: Increase melt temp by 10°C, boost packing pressure 15%, redesign gates.

Data sources: Industry reports from. For detailed technical parameters, consult machinery manuals or contact certified suppliers.