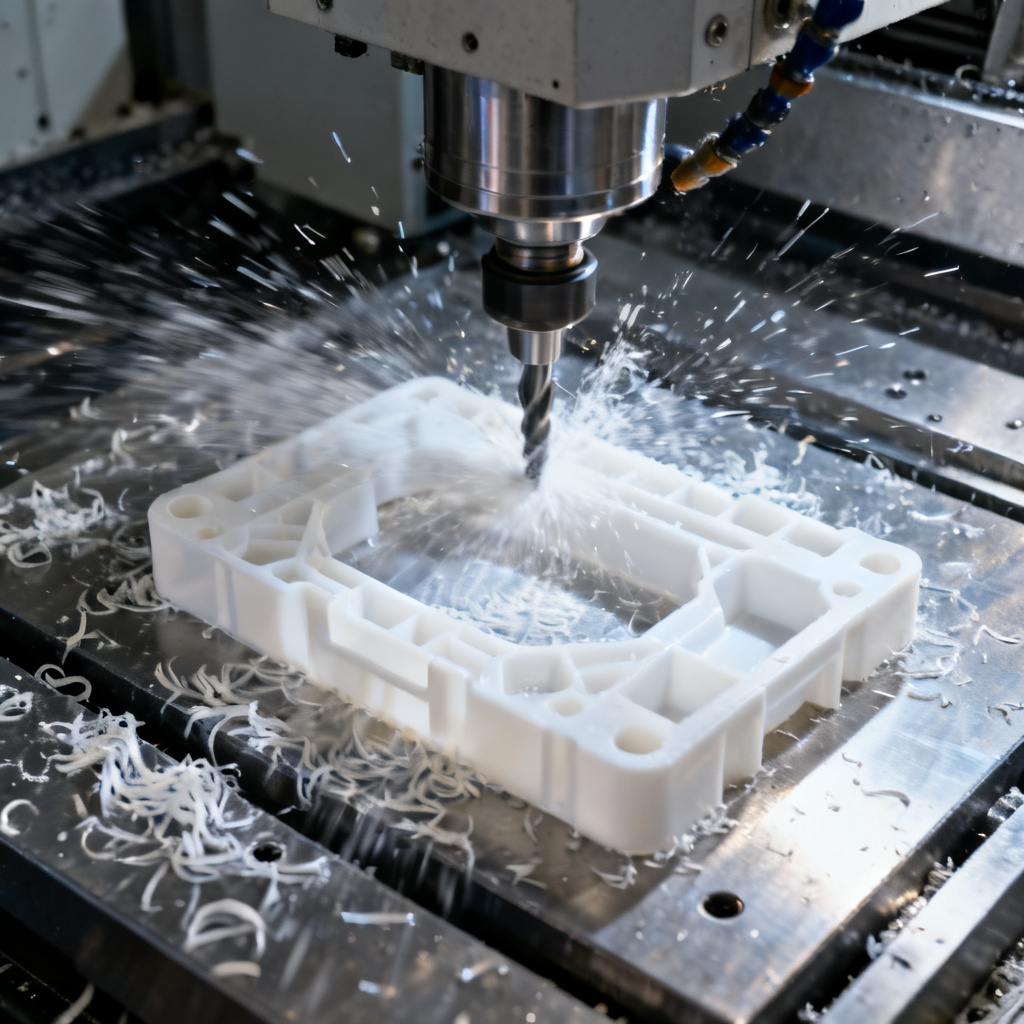

What is milling? It is a machining method that uses a tool to shape a workpiece on a usually movable table, although some milling machines also have a movable tool. Milling was originally a manual operation performed by workers. However, nowadays, most milling is completed by CNC milling machines, which use a computer to supervise the milling process. CNC milling can provide higher precision, accuracy, and productivity. But in some cases, manual milling is still useful. Manual milling requires a lot of technical skills and experience, thus shortening the turnaround time. It also has the additional advantage that manual milling machines are cheaper, and users don’t need to worry about programming the machine.

- Tool Movement Control

The core of CNC milling lies in the precise control of the movement of the milling cutter. The CNC system reads the pre – written machining program and converts the instructions into motion control signals for each coordinate axis of the milling cutter. These coordinate axes usually include the X, Y, and Z axes, corresponding to the length, width, and height directions of the workpiece respectively. By controlling the linkage of each axis, the milling cutter can perform cutting movements along various complex paths such as straight lines and curves on the workpiece surface. For example, when machining a medical component with a curved surface contour, the CNC system can accurately control the milling cutter to cut along the contour of the curved surface according to the program, so that the machined curved surface meets the design requirements.

- Milling Cutter Rotation and Cutting

The milling cutter rotates at a high speed driven by a motor, which is the key action to achieve cutting. The cutting edge of the milling cutter contacts the surface of the workpiece, and the excess material on the workpiece is removed through the cutting force generated by high – speed rotation. There are various types of milling cutters. According to the processing requirements, milling cutters of different shapes and sizes can be selected, such as flat – bottom milling cutters, ball – nose milling cutters, and end – mills. In the CNC processing of medical components, ball – nose milling cutters are often used to machine complex curved surfaces because they can better fit the shape of the curved surface and ensure machining accuracy.

- The Role of Cutting Parameters

Cutting parameters play a crucial role in CNC milling and directly affect the machining quality and efficiency. The main cutting parameters include cutting speed, feed rate, and depth of cut. The cutting speed refers to the instantaneous speed of a point on the cutting edge of the milling cutter relative to the workpiece, which determines the cutting force and heat generation during the cutting process. An appropriate cutting speed can ensure the durability of the milling cutter and the quality of the machined surface. The feed rate refers to the distance that the workpiece moves relative to the milling cutter in the feed direction per revolution or per stroke of the milling cutter. A reasonable feed rate can improve the machining efficiency, but an excessive feed rate may lead to a rough machined surface. The depth of cut refers to the depth that the milling cutter cuts into the workpiece each time, which is closely related to the machining efficiency and tool life. In the CNC processing of medical components, the control of these cutting parameters is particularly strict to ensure that the accuracy and surface quality of the machined components meet the requirements.

Common materials for CNC milling mainly include two categories: metals and non – metals. The choice of different materials depends on processing requirements, performance requirements, and the final application scenarios. The following are some common CNC milling materials:

- Metal Materials

Metal materials are widely used in CNC milling, mainly in fields such as aerospace, automotive manufacturing, and precision machinery.

- Aluminum Alloys

Aluminum alloys, due to their light weight, moderate strength, strong corrosion resistance, and good thermal conductivity, have become one of the most commonly used metal materials in CNC milling. Common grades include 6061, 7075, and 2024, among which 6061 aluminum alloy is the most common due to its good machinability and comprehensive performance.

- Stainless Steel

Due to its excellent corrosion resistance, high strength, and wear resistance, stainless steel is widely used in industries such as medical devices, food processing, and automotive parts. Common grades include 304, 316, 410, and 17 – 4PH. Among them, 316 has stronger corrosion resistance, and 17 – 4PH has higher strength and wear resistance.

- Carbon Steel

Carbon steel, because of its high strength, low cost, and good weldability, is often used for structural parts and mechanical components. Common types include 1018, 1045, and 4140. Among them, 1018 is suitable for general processing, while 4140 has higher hardness and wear resistance.

- Copper and Brass

Pure copper (such as C110), due to its excellent electrical and thermal conductivity, is often used in electronic components and electrical engineering. Brass (such as C360), because of its good corrosion resistance and easy processing, is often used for precision parts, valves, and joints.

- Tap: Taps are used to machine threads on materials such as metals or plastics. They can be divided into manual taps and automatic taps, with a wide variety of specifications. After being installed on a milling machine, they can efficiently machine internal threaded holes. Especially when machining softer materials such as plastics, brass, copper, and aluminum, taps are an ideal tool for thread machining.

- Drill Bit: Drill bits are used to drill round holes in materials such as wood or metal. After being installed on a milling machine, precise machining can be achieved. There are many types of drill bits, including flat drills and twist drills of different shapes and specifications. In addition, in CNC milling, drill bits are usually used to machine conical guide holes before formal drilling to prevent drilling deviation, thereby ensuring accurate hole diameters and improving machining quality.

Design for manufacturability (DFM) in CNC milling involves creating designs that are easy to produce and cost – effective. This includes considering part dimensions, standardization, and material selection.

- Part Dimensions

The dimensions of a part can significantly affect the cost and feasibility of CNC milling. Larger parts require more materials and time to machine, thus increasing the cost. On the other hand, precisely machining very small parts can be challenging. Therefore, it is crucial to design parts that are in line with the functions of the CNC milling machine.

- Standardization

Standardization can also reduce the cost of CNC milling. This involves designing parts that can be manufactured using standard tool sizes and avoiding complex features that require special tools. For example, adding internal corner radii to parts, avoiding thin walls and cross – sections of parts, and choosing larger features over smaller ones can help reduce the cost and complexity of the milling process.

Generally, milling is most suitable as an auxiliary or finishing process for machined workpieces to provide definition to part features such as holes, slots, and threads or to generate part features. However, this process can also be used to shape stock materials from start to finish. In both cases, the milling process gradually removes material to form the desired shape and part form.