1. What are CNC Machining Parts? How do they compare to traditional mechanical machining?

Simply put, CNC machining parts are components made by cutting and polishing raw materials (metal, plastic, wood, etc.) using “computer-controlled machine tools” (CNC = Computer Numerical Control). For example, the metal middle frame of a smartphone and the gears in a car engine are often made via CNC machining.

The biggest difference between CNC and traditional machining lies in “automation”: Traditional lathes and milling machines rely on workers to manually adjust tools and monitor processing, so part precision depends entirely on skill. CNC, however, operates automatically based on pre-programmed code—tool paths, rotation speed, and feed rate are all controlled by computers. Even after hours of continuous processing, it maintains consistent precision.

(The first time I visited my friend’s CNC factory, I saw a machine tool working alone, slowly “carving patterns” on an aluminum block—the hole position error was said to be only 0.01mm. I remembered watching an experienced worker operate a traditional lathe before, staring at the workpiece without blinking. The contrast was striking; no wonder precision parts now all use CNC.)

2. What core equipment is needed to make CNC parts? Do these machines have their own “specialties”?

There are three main types of core equipment, each with its own expertise—like “different craftsmen” in a factory:

- CNC Milling Machine: Good at “flattening surfaces, cutting grooves, and drilling holes”. For example, it mills the camera recesses on smartphone back covers or drills uniform small holes in metal plates. Vertical milling machines are the most common; they can process surfaces in multiple directions (up, down, left, right). My friend’s factory uses one to make metal brackets for computer cases, milling 4 symmetrical mounting holes in one go.

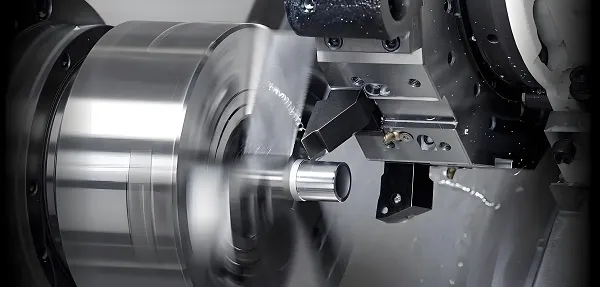

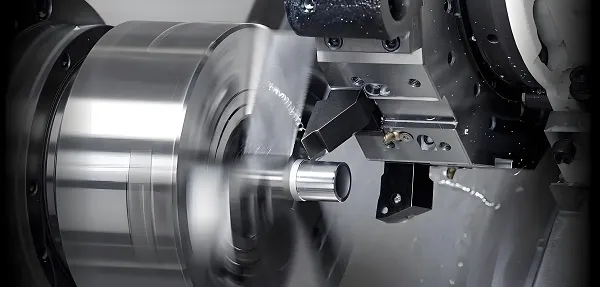

- CNC Lathe: Specializes in “circular parts” such as bearings, bolts, and metal liners for water cups. The workpiece rotates with the spindle, while the tool stays fixed to “cut”—it can make cylindrical surfaces smooth and round. Last time I watched it process stainless steel chopsticks: it hummed as it spun, and turned a rough blank into a smooth chopstick in minutes—10 times faster than manual polishing.

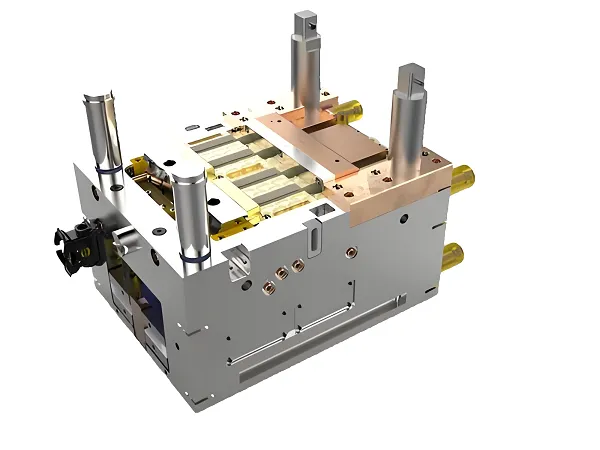

- CNC Machining Center: The “all-rounder” that can mill, drill, and tap (cut threads in holes). Some even have multiple spindles, allowing complex parts to be processed in one go. For example, a gearbox in a car transmission has flat surfaces, holes, and threads. In the past, 3 different machines were needed; now a single machining center can handle it all.

(My friend initially only bought a milling machine. Later, he received an order for drone parts—they required both groove milling and hole drilling. He had no choice but to buy a machining center for nearly 500,000 yuan. He joked, “CNC equipment is like a puzzle; if you’re missing one piece, you can’t take on the work.” Now I finally get what he meant.)

3. What steps does a CNC part go through from design to finished product? What “critical details” can’t be messed up in each step?

There are 6 steps in total—each is like “building blocks”; one mistake can ruin the whole process:

- Design & Modeling: First, draw a 3D model using CAD software. For example, if making a metal keychain, you need to clearly outline patterns and hole positions. This step requires precision: if the hole diameter is marked 1mm wrong, the finished keychain won’t fit a key ring later.

- Programming & Tool Path Calculation: Convert the 3D model into “G-code” (machine-readable instructions) using CAM software. This tells the tool where to start cutting, which path to take, and how fast to move. Programmers must avoid “tool collisions”—last year, a new programmer at my friend’s factory wrote code that made the tool crash into the workpiece. The tool broke, the workpiece was ruined, and the loss was nearly 1,000 yuan.

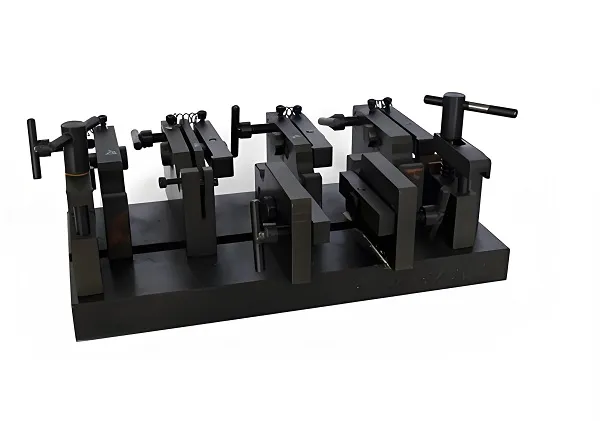

- Workpiece Clamping: Fix the raw material to the machine’s fixture. It needs to be tight enough to stay stable, but not so tight that it deforms. For example, when processing thin aluminum sheets, too loose and it wobbles; too tight and it bends. Workers usually place a soft rubber pad and adjust the pressure slowly.

- Test Cutting Verification: Let the machine cut a small section first, then measure if the dimensions are correct. For example, if processing a 50mm-long part and the test cut measures 50.02mm, adjust the feed rate in the program until the error is within 0.01mm.

- Formal Processing: The machine runs automatically according to the program. Workers don’t need to monitor it constantly, but they should check occasionally—for example, if metal shavings are jamming the tool or if there’s enough coolant (coolant reduces heat and keeps parts smooth).

- Inspection & Acceptance: Use calipers, micrometers, or even coordinate measuring machines to check precision. Defective parts need rework. Last time I watched them inspect an aerospace part; the inspection alone took 20 minutes. The worker said, “This part goes in an airplane—even a 0.005mm error is unacceptable.”

(Once I squatted to watch a keychain being processed. It took 15 minutes from clamping to finished product. What surprised me most was the test cutting step—the worker said, “I’d rather spend 2 extra minutes on test cutting than find out the whole batch is bad later.” This “slowing down to ensure quality” attitude really stuck with me.)

4. Where are CNC machining parts used? Are there examples we can touch in daily life?

From aerospace to daily necessities, CNC parts are everywhere. It’s clearer to split them into two categories:

- Industrial “Hard Demand” Fields:

Aerospace uses CNC to machine titanium alloy blades—this material is hard and tough, so ordinary machines can’t cut it. CNC’s high-speed tools “gnaw” out complex curves bit by bit, with precision controlled within ±0.005mm (otherwise, engine efficiency is affected).

The automotive industry relies on CNC for engine blocks—these have many holes and oil passages, and CNC drills them accurately in one go without switching machines.

Medical devices like stainless steel tweezers need their tips ground sharp and smooth by CNC to avoid scratching skin.

- Everyday Examples You Can Touch:

Smartphone metal middle frames—the fine matte texture you feel when holding your phone is milled by CNC.

Custom metal keychains—like a brass keychain engraved with a name. CNC-carved patterns are more three-dimensional than laser-engraved ones and won’t peel off.

Watch cases—especially stainless steel cases for mechanical watches. Those arcs and grooves are milled by CNC bit by bit; no wonder high-quality watch cases feel completely burr-free.

(Last year, I customized a CNC brass keychain with my cat’s pattern. When I got it, I checked the edges—it was much smoother than mass-produced keychains. The worker said, “CNC-carved patterns have consistent depth; manual carving can’t match that.” I’ve used it every day since, and it shines more with time.)

5. CNC machining has obvious advantages, but are there frustrating “pain points”? Can small factories handle them?

The advantages are indeed strong—high precision, ability to make complex parts, and labor savings via automation. But the pain points are real, especially for small factories:

- High Equipment Costs: A regular 3-axis machining center costs 200,000 to 300,000 yuan; a 5-axis one can exceed 1 million yuan. You also need supporting equipment like coolers and chip conveyors. The initial investment is at least 500,000 yuan. My friend spent half a year saving up before daring to buy two used machining centers.

- Small-Batch Orders Are Unprofitable: For example, if a customer wants 10 custom parts, programming and clamping take 2 hours, while processing only takes 1 hour. All costs are spread across 10 parts, making the unit price high—customers complain about the cost, and the factory makes no profit. My friend said, “We basically turn down orders under 50 pieces, unless they’re high-margin precision parts.”

- Hard to Recruit Programmers and Skilled Workers: A good CNC programmer needs to know CAD/CAM software and understand processing parameters for different materials (e.g., different rotation speeds for aluminum vs. steel). Their monthly salary is at least 15,000 yuan, and they’re still hard to find. A new hire at my friend’s factory kept making programming errors; in the end, they had to hire a senior worker to train them for 3 months.

- Lots of Waste Material, Hard to Dispose Of: Metal processing produces lots of iron and aluminum shavings. Though they can be sold, the price is low, and they take up space. Last time I visited the factory, there was half a ton of aluminum shavings piled in the corner. My friend said, “We have to wait until we have 1 ton before someone buys it—we only get around 2,000 yuan, which isn’t even enough to cover one day’s electricity bill.”

(Once my friend complained about a small order: the customer wanted 20 stainless steel brackets, and he only made 300 yuan profit in the end—hardly worth the trouble. He said, “CNC is like a ‘big eater’; it needs large-batch orders to be full. Small orders can’t satisfy it.” That really sums up the reality.)

6. What are the latest trends in CNC machining? Can they solve these pain points in the future?

The trends in recent years are clear—moving toward “smarter, cheaper, and more eco-friendly” solutions, which may gradually solve these pain points:

- Cost Reduction via Intelligence: Many CNC machines now connect to AI systems. For example, AI automatically adjusts cutting parameters—if a tool wears down during processing, AI slows the rotation speed to reduce defects. There are also automatic programming tools: previously, a programmer needed 2 hours to code a complex part; now software generates the code automatically, and the programmer only needs to tweak details—saving a lot of time. After installing an AI monitoring system last year, my friend’s factory reduced defect rates from 5% to 1%, earning thousands more each month.

- More Flexibility for Small-Batch Processing: “Small CNC machines” have emerged, costing only 50,000 to 80,000 yuan—perfect for small factories making small-batch parts. There are also “cloud programming platforms”: small factories don’t need to hire in-house programmers; they just upload drawings to the platform, and professional teams write the code for a one-time fee—cheaper than hiring someone.

- Waste Reduction via Green Practices: Modern CNC machines use servo motors, saving 30% more energy than old models. After replacing two machines with servo motors, my friend’s monthly electricity bill dropped by 1,500 yuan. Additionally, metal shavings can be combined with 3D printing—melt aluminum shavings into wire, then use 3D printing to make small parts. This increases material utilization from 70% to 90%, which is more eco-friendly and saves material costs.

- Higher Efficiency with Multi-Axis Machining: 5-axis and 6-axis CNC machines are becoming more common, capable of processing more complex parts. For example, a motorcycle frame joint used to require 3 machines; now a 5-axis machine can finish it in one go, saving clamping time and doubling efficiency.

(Last time I visited an intelligent CNC factory, there were few workers next to the machines—everything was monitored by computers. The AI even sent automatic alerts: if coolant was low, the system directly messaged the workers. My friend said, “In the future, small factories can also reduce costs with smart equipment—maybe small-batch orders will become profitable too.” I think this direction is really promising.)

Final Thoughts: CNC Machining Is Closer Than You Think, and Getting “Friendlier”

I used to think CNC was “only for big factories”. But after learning more, I realized it’s already part of daily life—from smartphone parts to custom accessories. While high equipment costs and small-batch challenges remain, with the development of smart technology and small machines, custom metal items may soon become cheaper and faster to make.

As my friend put it: “CNC isn’t just a ‘cold machine’—it’s a tool that turns ‘ideas into real objects’. Draw a design, and it can make it a reality. That ability to ‘precisely bring creativity to life’ is what makes it truly powerful.”