首页 » Introduction to CNC Services

Customized Online CNC Machining Service

Tolerance of ±0.005mm

Choose from more than 100 materials and over 20 surface treatments.

Certified to ISO 9001:2015, ISO 13485, ISO 14001:2015 and IATF 16949:2016.

100% Quality Inspection

Provide product inspection certificates.

Samples will be available within 7 days.

Goldcattle CNC Customized Service

- 26 years in the CNC machining manufacturing industry

- A processing workshop in a factory building covering thousands of square meters

- Customization based on drawings or samples

- Processing of metal and non – metal materials

- Hundreds of CNC processing equipment

- Precision of ±0.005mm

- A professional technical R & D team

- A 100% quality inspection process

- Delivery to all parts of the world

Our CNC machining services

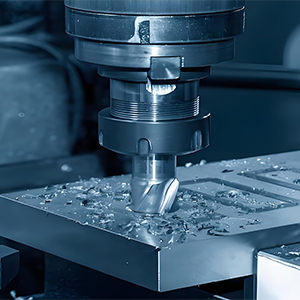

Milling

Process features: By using a rotating multi – edged milling cutter (such as end mills, slot drills, ball – nose mills, etc.) to cut materials, it can machine complex structures like planes, grooves, three – dimensional surfaces, and cavities.

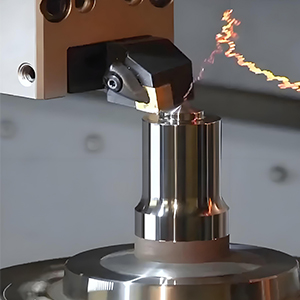

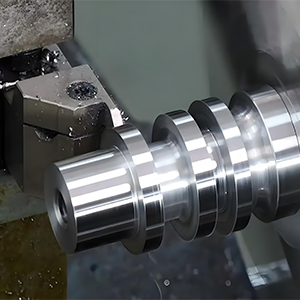

Turning

The workpiece rotates while the cutting tool feeds axially or radially to machine rotational parts (shaft – type and disc – type parts).

Drilling and Hole Machining

Drilling and hole machining include processes such as drilling, reaming, boring and boring. Choose according to accuracy to adapt to hole machining in various scenarios.

Grinding

The surface of the workpiece is ground with a grinding wheel (abrasive particles) to achieve ultra – high precision (tolerance of ±0.0005mm) and surface quality.

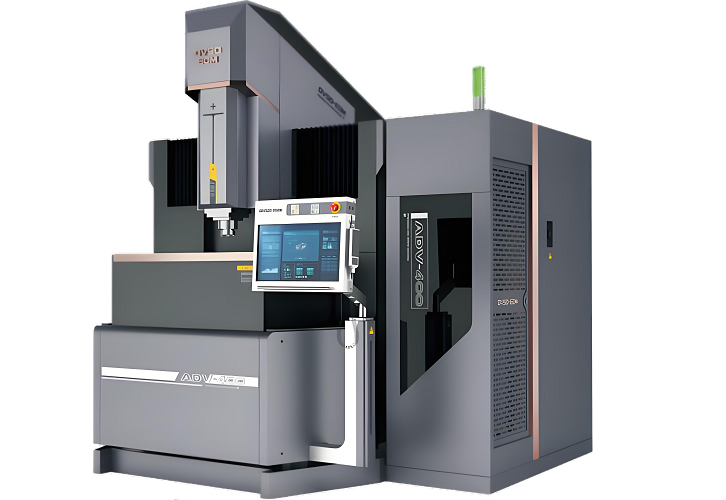

Electrical Discharge Machining

Material is eroded through pulsed discharge between the electrode and the workpiece. It is suitable for materials with high hardness (such as quenched steel, cemented carbide) or complex structures.

Tapping & Thread Milling

Tapping is used for internal thread machining, efficiently forming threads with a tap. Thread machining includes various processes to meet different precision requirements.

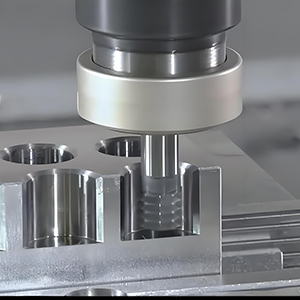

5 – Axis Machining

Through the linear motion of the X/Y/Z three axes and the rotation of the A/C two axes, complex curved surfaces (such as aerospace blades, automotive body panel molds) can be machined in one clamping.

Broaching

A broach (with multiple rows of progressive cutting edges) is used to machine high – precision internal or external surfaces (such as spline holes and keyways) in one go. It is suitable for mass production.

Gear Hobbing & Cutting

Gear hobbing adopts the generating method, which has high efficiency and strong adaptability. It can machine spur gears, helical gears and worm gears, with an accuracy grade of 6 – 9.

Rapid Prototyping

Manufacture plastic/metal prototype parts through CNC machining to replace 3D printing and achieve higher strength and precision (such as medical device samples).

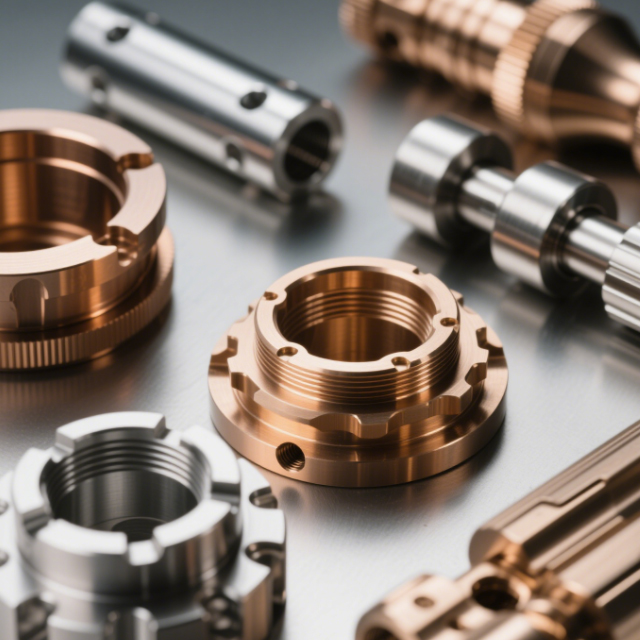

CNC - Machined Parts

CNC Processing Material List

| Material Name | Category | Density (g/cm³) | Hardness | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Thermal Conductivity (W/(m·K)) | Melting Point (°C) | Machining Properties | Primary Applications |

|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum Alloys | Light Metal Alloys | 2.65–2.85 | HB 40–150 | 180–650 | 100–580 | 5–15 | 150–200 | 577–660 | Excellent machinability, easy chip breaking; suitable for HSS/carbide tools; note tool wear and surface oxidation treatment. | Aerospace (frames, impellers), automotive (wheel hubs, structural parts), electronics (phone casings, heat sinks). |

| Stainless Steels | Iron-Based Alloys | 7.75–8.05 | HB 150–300/HRC 20–35 | 500–1000 | 200–500 | 20–40 | 15–25 | 1370–1450 | High viscosity, high cutting force; requires rigid machines and coated carbide/ceramic tools; adequate cooling needed. | Medical devices (surgical instruments), food equipment (pipes), industrial equipment (valves, flanges). |

| Copper & Copper Alloys | Non-Ferrous Metals | 8.6–9.0 | HB 40–150 | 200–500 | 100–300 | 20–40 | 350–400 | 1083 | Good machinability, prone to tool adhesion; requires sharp tools and lubrication; suitable for precision machining. | Electronics (connectors, heat sinks), plumbing (valves), musical instruments (brass pipes). |

| Titanium Alloys | Difficult-to-Cut Alloys | 4.4–4.5 | HB 250–350/HRC 30–40 | 900–1200 | 800–1100 | 8–15 | 6–15 | 1668 | Poor thermal conductivity, high cutting temperature; requires special carbide/diamond tools; low cutting speed to prevent tool adhesion. | Aerospace (blades, landing gears), medical (artificial joints), sports equipment (golf club heads). |

| Magnesium Alloys | Lightest Metal Alloys | 1.7–1.85 | HB 30–60 | 150–300 | 80–180 | 8–12 | 150–180 | 650 | Excellent machinability, prone to oxidation/combustion; avoid high-speed dry cutting; use kerosene for cooling. | Automotive (dashboard brackets), 3C products (laptop casings), aviation (secondary structures). |

| Carbon Steel (Low/Medium Carbon) | Iron-Based Alloys | 7.85 | HB 100–200/HRC 15–30 | 400–700 | 250–400 | 25–35 | 45–55 | 1420–1500 | Moderate machinability; medium carbon steel requires preheating; prone to burrs; suitable for general-precision machining. | Mechanical parts (gears, shafts), molds (templates), construction (steel structures). |

| Tool Steels (e.g., SKD11) | Tool Steels | 7.85 | HRC 50–60 | 1500–2000 | – | 2–5 | 20–30 | 1350 | High hardness; requires carbide/ceramic tools; often annealed before machining, then heat-treated. | Injection molds, stamping dies, precision cutting tools. |

| Zinc Alloys | Die-Casting Alloys | 6.6–6.75 | HB 60–100 | 200–300 | 100–200 | 1–5 | 110–120 | 419 | Good machinability, prone to brittleness; suitable for rapid machining; easy to plate. | Hardware parts (locks, zipper heads), electronic casings (set-top boxes). |

| Nickel Alloys (e.g., Inconel) | High-Temperature Alloys | 8.2–8.5 | HB 200–400/HRC 35–50 | 1000–1500 | 600–1000 | 10–20 | 10–20 | 1390–1425 | Severe work hardening; requires extremely low cutting speed and high-pressure cooling; use diamond/CBN tools. | Aircraft engines (turbine blades), chemical industry (corrosion-resistant pipes). |

| Cobalt-Chromium Alloys | Medical Alloys | 8.3–8.9 | HB 250–350/HRC 30–40 | 1200–1400 | 800–1000 | 10–15 | 10–15 | 1350–1400 | High wear resistance, high cutting force; requires high-precision machines and CBN tools; surface polishing needed. | Medical implants (teeth, joints), high-end watches (cases). |

| Precious Metals (Gold/Silver) | Special Metals | 19.3/10.5 | HB 20–30 | 100–300 | 50–150 | 30–40 | 290/420 | 1064/962 | Excellent ductility, prone to tool adhesion; requires ultra-precision tools and constant temperature; suitable for micro-machining. | Jewelry, electronics (high-frequency component plating), precision instruments (contacts). |

| Tungsten/Molybdenum Alloys | Refractory Metals | 19.3/10.2 | HB 300–500 | 1000–3000 | 800–2500 | 1–5 | 170/135 | 3422/2623 | High melting point and hardness; requires diamond tools and extremely slow feed rate; very high machining cost. | Aerospace (high-temperature components), electronics (filaments, heat sinks). |

| Material Name | Category | Density (g/cm³) | Hardness | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Thermal Conductivity (W/(m·K)) | Melting/Softening Point (°C) | Machining Properties | Primary Applications |

|---|---|---|---|---|---|---|---|---|---|---|

| ABS | General-Purpose Plastic | 1.02–1.05 | HB 80–100 | 30–50 | 25–40 | 20–40 | 0.15–0.2 | 105 (Softening Point) | Good machinability, prone to melting; control cutting temperature to avoid burrs; usable with HSS tools. | Model making, home appliance casings, toys (LEGO). |

| Nylon (PA) | Engineering Plastic | 1.12–1.15 | HB 90–120 | 50–80 | 40–60 | 150–300 | 0.25–0.3 | 215–260 (Melting Point) | Hygroscopic, requires drying; prone to deformation during cutting; needs sharp tools and cooling. | Mechanical parts (gears, bearings), automotive (engine components), 3D printing materials. |

| Acrylic (PMMA) | Optical Plastic | 1.18–1.20 | HB 100–120 | 50–70 | 45–60 | 5–10 | 0.17–0.2 | 105 (Softening Point) | Brittle, prone to chipping; requires ultra-high-speed cutting and lubrication; suitable for high-gloss surface machining. | Optical lenses, billboards, instrument panels. |

| PVC | General-Purpose Plastic | 1.3–1.45 | HB 70–100 | 40–50 | 30–40 | 5–20 | 0.16–0.19 | 80–85 (Softening Point) | Chlorine content may corrode tools; use carbide tools; produces harmful gases during machining; requires ventilation. | Pipes, panels, packaging materials. |

| POM (Acetal) | Engineering Plastic (Delrin) | 1.41–1.43 | HB 120–130 | 60–75 | 50–65 | 25–75 | 0.22–0.3 | 175 (Melting Point) | Low friction, excellent machinability, prone to crystallization; control feed rate to avoid burrs. | Precision gears, bearings, valve components. |

| PEEK | High-Performance Engineering Plastic | 1.3–1.45 | HB 120–140 | 90–100 | 80–90 | 30–50 | 0.25–0.3 | 343 (Melting Point) | High temperature resistance and hardness; requires carbide/diamond tools; preheat to over 150°C before machining. | Aerospace (bearings), medical (sterilization equipment), semiconductors (high-temperature components). |

| Carbon Fiber Composites | Fiber-Reinforced Plastic | 1.4–1.6 | HB 150–200 | 1000–2000 (Longitudinal) | – | 0.5–1 | 0.5–1 (Longitudinal) | Resin Matrix ≈200 (Decomposition) | Anisotropic, prone to delamination; use diamond tools and high-pressure dust extraction; cutting speed >10,000 rpm. | Aerospace (fuselage skins), racing cars (chassis), sports equipment (rackets). |

| Glass Fiber (GFRP) | Fiber-Reinforced Plastic | 1.8–2.1 | HB 180–250 | 500–1000 (Longitudinal) | – | 1–2 | 0.3–0.5 | Resin Matrix ≈180 (Decomposition) | Fibers wear tools easily; use diamond/tungsten carbide tools; dust protection needed during machining. | Marine (hulls), wind energy (blades), automotive (bumpers). |

| Wood | Natural Material | 0.4–0.8 | HB 10–30 | 40–60 (Along Grain) | – | 5–10 | 0.15–0.2 | 230 (Ignition Point) | Easy to machine; adjust feed direction according to grain; use HSS tools; surface polishing needed. | Furniture, handicrafts, models, musical instruments (guitar bodies). |

| Stone (Marble/Granite) | Natural Stone | 2.6–2.8 | Mohs 3–7 | 50–200 (Compressive) | – | <1 | 2–3 | >1500 (Decomposition) | High hardness; requires diamond tools and water cooling; slow machining speed; dust control needed. | Architectural decoration (reliefs), tombstones, precision instrument bases. |

| Ceramics (Alumina/Zirconia) | Industrial Ceramics | 3.0–6.0 | Mohs 8–9 | 200–500 (Compressive) | – | <0.1 | 15–30 (Alumina) | 2050 (Alumina Melting Point) | Extremely high hardness; only machinable with diamond tools; requires ultra-precision machines and nanometer-level control. | Electronics (circuit substrates), aerospace (thermal barrier coatings), precision bearings. |

| Foam (EPS/EVA) | Lightweight Material | 0.02–0.2 | Shore 10–50A | 1–5 | – | 10–50 | 0.03–0.05 | 80–150 (Softening Point) | Extremely low cutting resistance, prone to tool adhesion; requires sharp blades and vacuum clamping. | Model prototyping, packaging materials, soundproof components. |

| PSU/PI | High-Temperature Engineering Plastics | 1.2–1.4 | HB 130–150 | 70–90 | 60–80 | 40–60 | 0.2–0.3 | 300–400 (Melting Point) | Requires high-temperature drying before machining; wear-resistant tools needed; suitable for high-precision, high-temperature parts. | Aerospace (connectors), semiconductors (wafer fixtures). |

Why choose us?

01/

High – quality Parts

02/

Advanced Workshop

03/

Powerful logistics

A corner of the workshop and equipment

MAZAK

Attribute: Five-axis machining center, an environmentally friendly model in the NEO series.

Characteristic: Five-axis simultaneous machining of complex parts, suitable for materials such as aluminum alloy and steel.

Advantage: High precision + low energy consumption, carbon emissions reduced by more than 30%, and convenient automated operation.

Fanuc

Attribute: Drilling and tapping center, focusing on the 3C and precision mold fields.

Characteristic: High-speed drilling/tapping/milling, fast tool change, suitable for small precision parts.

Advantage: Fanuc numerical control system with precise response, strong equipment durability and low maintenance cost.

Okuma

Attribute: Horizontal machining center, suitable for high-load continuous production.

Characteristic: High-rigidity structure, multi-station processing of large metal parts (such as aerospace components).

Advantage: Self-developed numerical control system matches the hardware, and has strong stability in 24-hour continuous processing.

DMG MORI

Attribute: Five-axis machining center, serving high-end manufacturing such as aviation and automotive.

Characteristic: Five-axis simultaneous machining of complex curved surfaces, with built-in measurement system to compensate for errors.

Advantage: High-rigidity structure + powerful numerical control system, supports flexible processing strategies, and has a complete after-sales system.

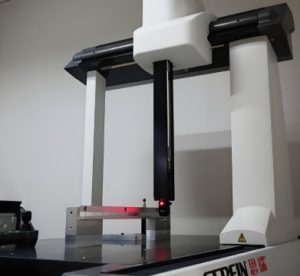

inspection equipment

We have professional inspection equipment and can provide product inspection services.

Xiamen Goldcattle

Custom CNC Parts Procurement FAQ

- Technical Drawings: CAD files (e.g., STEP/IGS) or clear 2D engineering drawings (with dimensions, tolerances, and surface roughness specified);

- Material Requirements: Specified material type (e.g., Aluminum 6061, Stainless Steel 304) and performance standards (e.g., tensile strength, heat treatment status);

- Quantity & Processes: Order quantity, surface treatment requirements (e.g., anodizing, electroplating), and special processes (e.g., thin-wall machining, precision grinding);

- Lead Time: Clear project timelines to assess production scheduling.

A: Low-volume customization is supported, with an MOQ of 1 piece (prototype). Volume orders (≥50 pieces) qualify for unit price discounts. Specifics may vary based on part complexity, material cost, and process difficulty.

- Material Cost: Precious metals (e.g., titanium alloy, Inconel) or specialty plastics (e.g., PEEK) incur higher costs;

- Machining Difficulty: Complex structures (deep cavities, thin walls, multi-curved surfaces) and high-precision requirements (below ±0.01mm) increase labor hours;

- Surface Treatment: Specialized processes like electroplating or hard anodizing cost more than standard treatments.Cost optimization tips:

- Provide standardized drawings (reduce design revisions);

- Consolidate orders for similar parts;

- Accept alternative materials (e.g., use 6061 instead of 7075 to lower costs without compromising performance).

- Prototype Stage: A sampling fee (covering material, programming, and tooling costs) is required, with a lead time of 5–15 working days (depending on complexity);

- Volume Orders: Sampling fees are fully deductible from the order value for quantities ≥5000 pieces.

- Metals: Aluminum alloys (6061/6082/7075), steels (carbon steel, stainless steel 304/316/420, tool steel), copper/brass, titanium alloys (TC4), nickel-based alloys, etc.;

- Non-metals: ABS, PC, nylon, POM, acrylic, PEEK, carbon fiber composites, etc.Material test reports (e.g., SGS certification, material certificates) are available to ensure compliance with ASTM, GB, ISO, and other standards.

- Metals: Anodizing (natural/colored), electroplating (nickel/chrome/gold), painting, passivation, blackening, hard anodizing;

- Non-metals: Spraying, silk screening, electroplating (after conductive treatment), polishing (mechanical/chemical).One-stop services are supported, with full control from machining to post-processing to avoid multi-supplier errors.