It should be noted that traditionally the term “metal stamping of leather” is not a directly corresponding technical term, since leather, as a flexible material, is not directly processed by metal stamping. However, it can be understood as a concept that combines elements of leather processing with metal stamping or a similar process technology, i.e. it may refer to the process of stamping leather using a metal die, or to the combination of a metal part with a leather material by means of a specific process. For the purposes of this presentation, we will focus on the latter – a hypothetical product manufacturing process combining leather and metal stamping technology.

1. Principle of leather-metal stamping technology

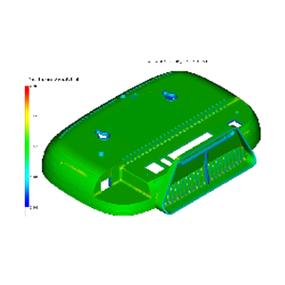

In technical principle, leather metal stamping can be seen as a combination of two separate but interrelated processes: firstly, metal stamping, used to manufacture precision metal parts; and secondly, leather processing, including cutting, embossing, sewing, etc., to combine the leather with the metal parts. In some high-end customized products, special stamping dies may be used to emboss complex patterns or textures directly onto the leather to simulate the effect of metal stamping, but this is still essentially part of leather processing.

2. Leather metal stamping products customization

Customization of leather metal stamping products usually involves a complex process, including:

Design: Designing the appearance, structure and function of the product according to the customer’s needs.

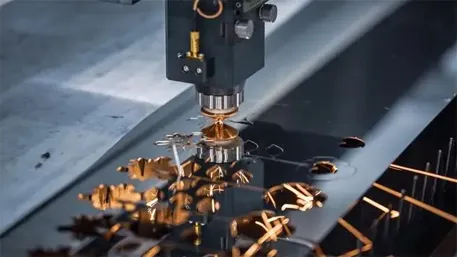

Metal parts stamping: using precision stamping dies to manufacture metal parts such as fasteners, decorative parts, etc.

Leather processing: Cutting, embossing and punching leather to fit metal parts.

Assembly: assembling metal parts with leather materials by sewing, gluing or other means.

Post-processing: including cleaning, finishing, quality inspection and packaging.

3. Leather metal stamping material introduction

Material:

Leather: natural leather (e.g. cowhide, sheepskin) or artificial leather can be used, and the suitable material can be selected according to the use of the product and the budget.

Metal: commonly used in stamping metal including stainless steel, aluminum alloy, brass, etc., with high strength, corrosion resistance and beautiful features.

Characteristics:

Leather:

Soft and comfortable, good touch feeling.

Good breathability, suitable for long time use.

Wear-resistant, easy to maintain.

Beautiful appearance, strong plasticity.

Metal:

High strength, provide structural support.

Corrosion-resistant, prolonging the service life of the product.

Exquisite surface treatment, enhance product texture.

Strong processability, suitable for complex shapes and patterns of stamping.

4. Leather metal stamping product characteristics

Products: Leather metal stamping products are widely used in fashion accessories (such as handbags, wallets, belts), furniture decoration, car interiors and other fields.

Durability: After careful design and manufacturing, the products have high durability and can withstand the wear and tear of daily use.

Aesthetics: The perfect combination of metal and leather gives the product a unique sense of beauty and texture, enhancing the overall grade.

Weight: Compared with all-metal products, leather metal stamping products are lighter and easier to carry and use.

Customization: Highly customized production process to meet the individual needs of different customers.

Environmentally friendly: Selection of environmentally friendly materials and processes to reduce the impact on the environment.

Leather Metal Stamping FAQ

Q1: What are the advantages of leather metal stamping products?

A1: Leather metal stamping products combine the comfort of leather and the sturdiness of metal, which is both beautiful and practical, and at the same time has a high degree of customization and durability.

Q2: How to maintain leather metal stamping products?

A2: For maintenance, avoid prolonged exposure to sunlight and humidity, clean regularly with professional leather cleaner and care with leather conditioner, metal parts can be wiped with a soft cloth, avoid using chemical cleaners.

Q3:How long is the production cycle of leather metal stamping products?

A3:The production cycle varies depending on the complexity and customization of the product, generally from design to finished product takes weeks to months.