Global Market Size

Regional Distribution Pattern

- Asia-Pacific Region: Accounts for approximately 48% of global production capacity, with China, India, and Southeast Asian countries contributing the main growth

- China: Produced about 128 million tons of plastic molded products in 2023, accounting for over 35% of global total production

- North American Market: Reached approximately $98 billion in 2023, representing 16.7% of global market share

- European Market: Valued at around €86 billion in 2023, with Germany, Italy, and France as major production bases

Core Advantages

- Lightweight: Density is only 1/4-1/8 of metal, significantly reducing product weight

- Cost-effective: Low raw material costs, high molding efficiency, suitable for mass production

- Corrosion-resistant: Excellent chemical stability, resistant to various chemical substances

- Easy processing: Mature molding processes, capable of manufacturing complex shapes and precision structures

- High design freedom: Enables complex geometries and multi-functional integrated designs

Technical Principles of Plastic Molding

Basic Principles

Technical Characteristics

- Material Melting: Plastic pellets are melted into a viscous flow state in the heating system

- Pressure Injection: Molten plastic is injected into the mold cavity under high pressure

- Cooling and Solidification: The melt cools and solidifies into a solid state in the mold

- Demolding and Part Removal: The mold opens and the molded part is removed

Detailed Molding Processes

Injection Molding

Technical Parameters

- Injection Pressure: 50-150MPa

- Injection Speed: 50-200mm/s

- Barrel Temperature: 150-300°C (varies by material)

- Cycle Time: 30 seconds – 5 minutes

Application Scope

- Precision Components: Electronic connectors, medical device parts

- Large Structural Parts: Automotive bumpers, instrument panels

- Thin-wall Products: Mobile phone cases, home appliance components

Extrusion Molding

Process Characteristics

- Continuous Production: 24-hour continuous production capability with extremely high efficiency

- Diverse Profiles: Can manufacture pipes, sheets, rods, films, etc.

- Low Equipment Investment: Relatively lower investment cost compared to injection molding equipment

Application Fields

- Construction Sector: Plastic window/door profiles, water supply pipes

- Packaging Sector: Plastic films, strapping bands

- Electronics Sector: Wire/cable insulation, heat shrink tubes

Blow Molding

Main Types

- Extrusion Blow Molding: Used for manufacturing hollow products like bottles and containers

- Injection Blow Molding: Used for manufacturing high-precision hollow products

- Stretch Blow Molding: Used for manufacturing high-strength transparent bottles

Technical Advantages

- Specialized for Hollow Products: The only process capable of manufacturing hollow plastic products

- Excellent Integrity: Seamless products with high strength

- Cost-effective: Suitable for mass production with low unit cost

Compression Molding

Suitable Materials

- Thermosetting Plastics: Phenolic resins, epoxy resins, etc.

- High-viscosity Thermoplastics: Some engineering plastics

Application Characteristics

- Suitable for Thick-walled Products: Can manufacture large thick-walled structural parts

- Fiber-reinforced Materials: Suitable for glass fiber-reinforced plastics

- Low-cost Molds: Relatively simple mold structure with lower cost

Material Selection and Performance Analysis

Comparison of Common Materials

|

Performance Indicator

|

PP Polypropylene

|

ABS Acrylonitrile Butadiene Styrene

|

PC Polycarbonate

|

|

Density

|

0.9g/cm³

|

1.05g/cm³

|

1.2g/cm³

|

|

Melting Point

|

160°C

|

105-110°C

|

220-230°C

|

|

Heat Resistance

|

100-150°C

|

70-80°C

|

130°C

|

|

Impact Strength

|

Low (requires modification)

|

High (8-30kJ/m²)

|

Very High (60-80kJ/m²)

|

|

Transparency

|

Semi-transparent

|

Opaque

|

Highly transparent (>90%)

|

|

Cost

|

Low ($1,200-1,500/ton)

|

Medium ($1,800-2,200/ton)

|

High ($3,000-4,500/ton)

|

|

Processing Difficulty

|

Easy (low-temperature injection)

|

Easy molding (good flowability)

|

High (requires high temperature/pressure)

|

|

Environmental Friendliness

|

Food-grade (non-toxic)

|

Contains styrene (requires treatment)

|

Recyclable (needs sorting)

|

Material Selection Guide

PP Polypropylene

- High-temperature Resistance: Smart sockets, lamp structural components (150°C resistance)

- Food Contact: Food packaging containers, medical device housings

- Low-cost Mass Production: Daily necessities, packaging materials

ABS Plastic

- High Appearance Requirements: Appliance housings, automotive interior components

- High Dimensional Stability Requirements: Instrument panel frames, center console panels

- Cost-performance Priority: Smart switches, remote control housings

PC Polycarbonate

- High Transparency Requirements: Smart panels, camera housings (>90% light transmission)

- High Strength Requirements: Safety protection equipment, helmet visors

- Optical Applications: Optical lenses, VR glasses

Product Customization and Quality Control

Customization Process

- Requirements Analysis

-

- In-depth communication to clarify product shape, dimensions, and performance requirements

-

- Analysis of usage environment and functional needs

-

- Development of technical specifications and acceptance criteria

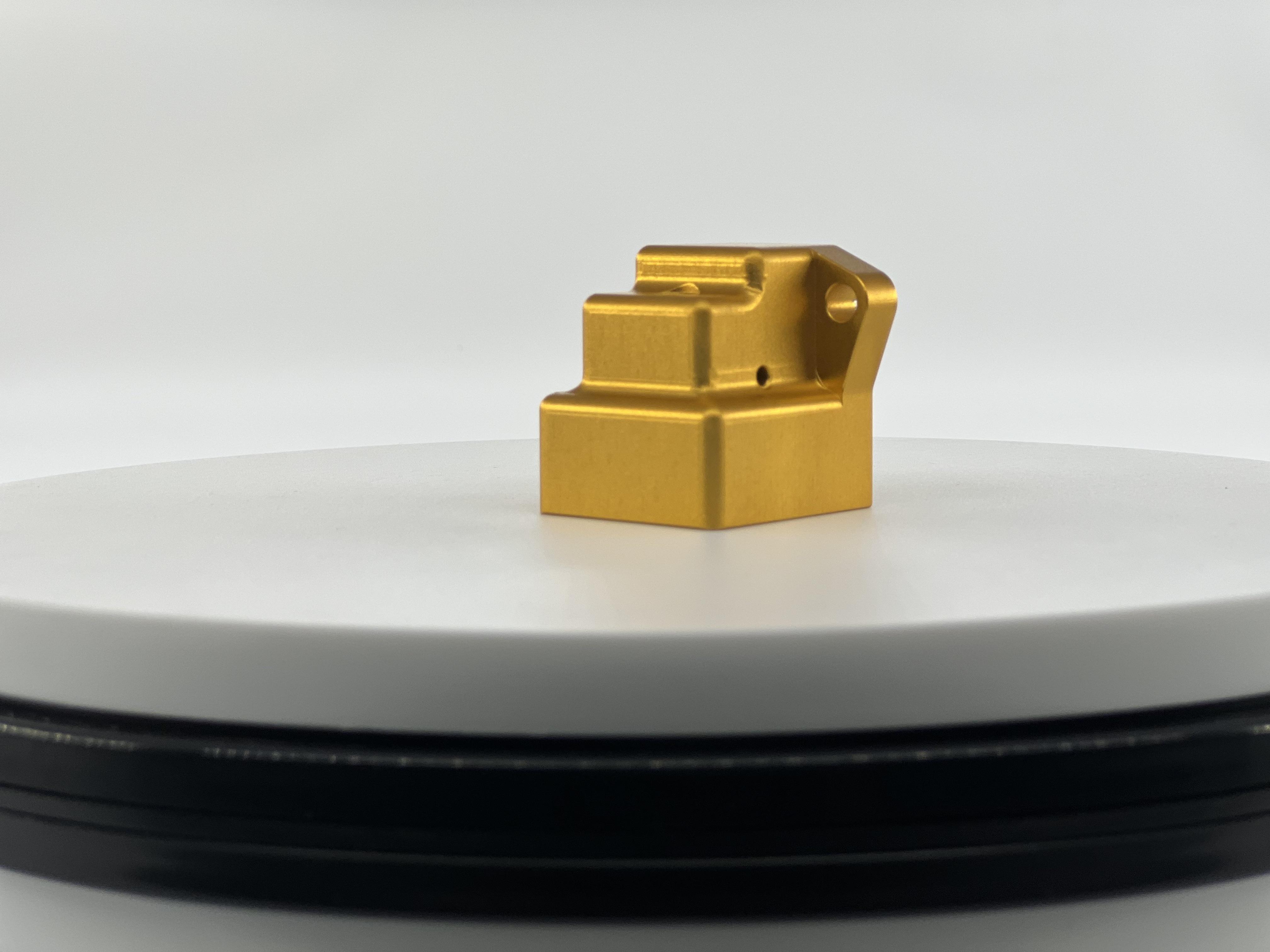

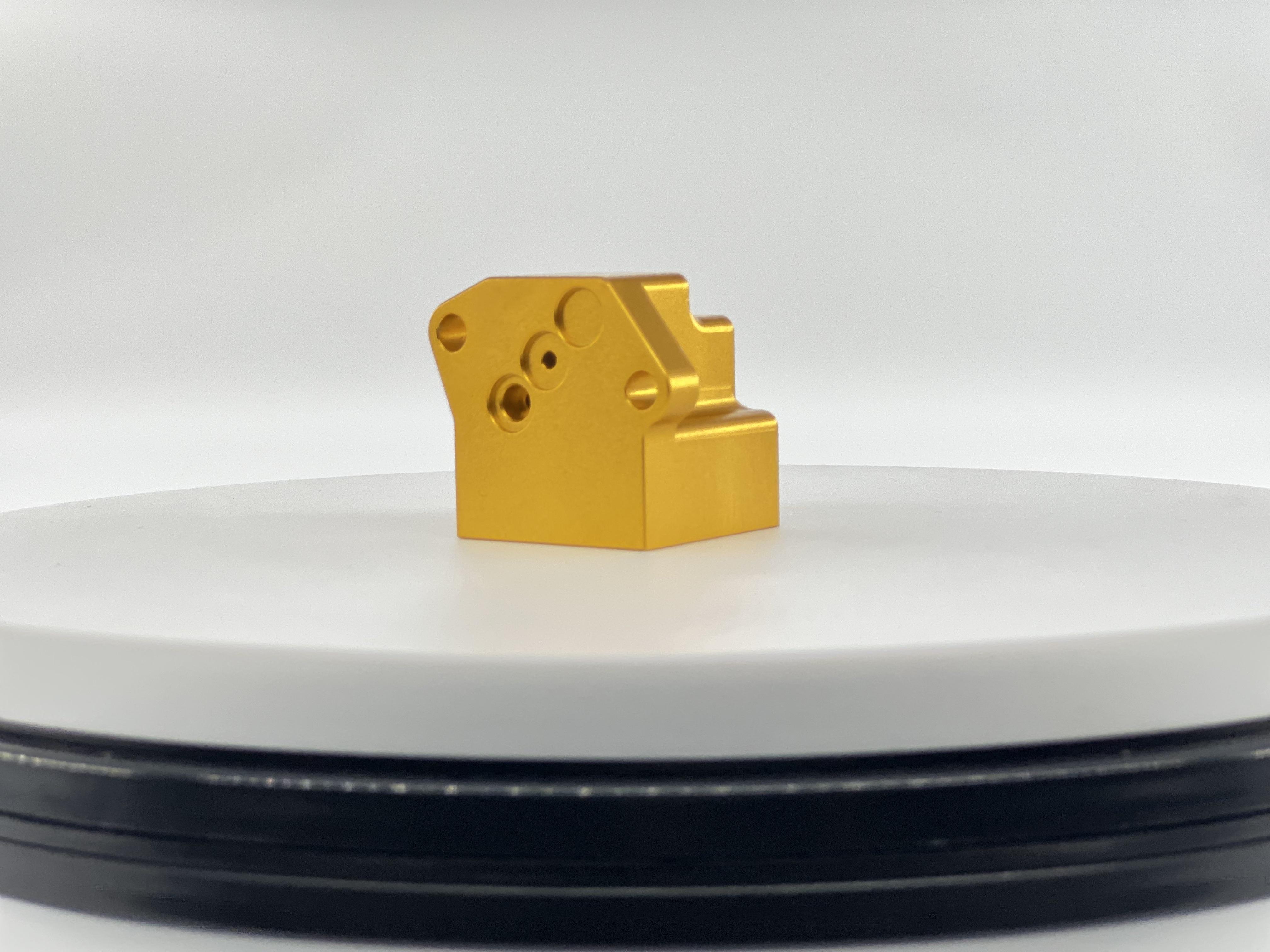

- Mold Design

-

- Mold structure design based on customer requirements

-

- Optimization of mold cooling and venting systems

-

- Ensuring reasonable mold structure and ease of processing

- Mold Manufacturing

-

- CNC machining centers for mold manufacturing

-

- Precision machining to ensure mold accuracy and durability

-

- Mold testing and adjustments

- Molding Production

-

- Raw material preprocessing (drying, color matching, etc.)

-

- Process parameter optimization and setting

-

- Mass production and process monitoring

- Quality Inspection

-

- Dimensional accuracy testing (coordinate measuring machine)

-

- Appearance quality inspection

-

- Performance testing and certification

Quality Control System

ISO9001 Quality Management System

Key Quality Indicators

- Defect Rate: ≤2% (industry average 3-8%)

- Customer Complaint Rate: ≤1 complaint/month

- Process Parameter Compliance Rate: ≥98%

- Mold Maintenance Plan Completion Rate: 100%

Testing Equipment

- Coordinate Measuring Machine: Dimensional accuracy testing (±0.01mm)

- Colorimeter: Color consistency testing

- Impact Testing Machine: Mechanical performance testing

- Heat Deflection Temperature Tester: Heat resistance performance testing

Application Fields and Market Prospects

Automotive Industry Applications

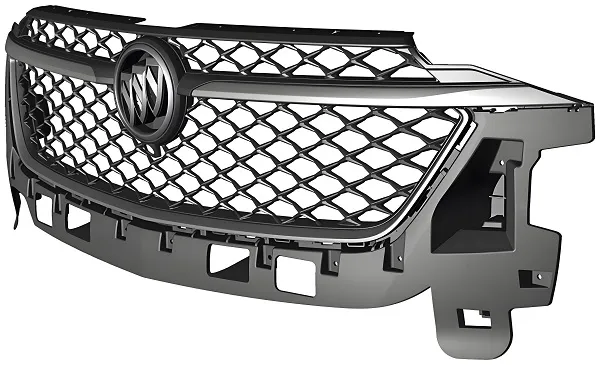

Main Applications

- Body Structural Components: Bumpers, door panels, instrument panels

- Interior Components: Seats, center consoles, steering wheels

- Functional Components: Intake manifolds, fuel tanks, electronic module housings

Technical Requirements

- Lightweighting: New energy vehicles use up to 186kg of engineering plastics per vehicle

- Heat Resistance: Components around the engine need to withstand temperatures above 120°C

- Impact Resistance: Bumper cantilever beam impact strength needs to be ≥20kJ/m²

Electronics Industry Applications

Precision Electronic Housings

- Mobile Phone Cases: Thickness 0.3-0.8mm, precision ±0.05mm

- Smart Watches: Complex curved surface design, high-gloss surface

- Connectors: Miniaturized design, multi-cavity mold molding

Technical Challenges

- Miniaturization: Wearable devices demand micron-level precision

- Thin-wall Technology: 0.3mm ultra-thin structural parts with ±0.01mm tolerance control

- High Gloss: Surface roughness Ra ≤0.2μm

Medical Industry Applications

Medical-grade Material Requirements

- Biocompatibility: Compliant with ISO10993 standards

- Cleanliness: Class 7 cleanroom production

- Traceability: Complete production records and batch management

Typical Applications

- Syringe Components: High-precision fit, leak-proof

- Surgical Instruments: High strength, sterilization-resistant

- Diagnostic Equipment: Optical-grade transparent parts, high precision

Packaging Industry Applications

Sustainable Development Trends

- Recycled Plastics: Approximately 22% of global plastic molded products used recycled materials in 2023

- Bio-based Materials: Growing applications of biodegradable materials like PLA and PHA

- Lightweight Design: Reducing material usage, lowering costs and environmental impact

Technology Development Trends

Intelligent Production

- AI-optimized Processes: AI algorithms optimize injection parameters and predict defect risks

- IoT Monitoring: Real-time equipment status monitoring and predictive maintenance

- Digital Twin: Establishing digital models of production processes to optimize efficiency

Green Manufacturing

- Servo Energy-saving Injection Molding Machines: Account for 78% of market, reducing energy consumption by 30%

- Closed-loop Waste Recycling: 100% recycling of production waste

- Chemical Recycling Technology: Establishing commercial channels for high-end recycled materials

Material Innovation

- Bio-based Plastics: Corn starch-based PP reduces carbon footprint by 30%

- Nanocomposites: 50% increase in surface hardness, replacing some metals

- Paint-free Technology: Reducing VOC emissions and lowering costs

Process Innovation

- 3D Printing Molds: Rapid prototyping, shortening development cycles

- Multi-material Injection: Achieving integrated molding of different materials

- Micro-injection Technology: Manufacturing micron-level precision components

Frequently Asked Questions

Q1: What are the main advantages of plastic molded parts?

Q2: How to select the appropriate plastic material?

- Product functional requirements (strength, heat resistance, transparency, etc.)

- Operating environment conditions (temperature, chemical exposure, mechanical stress, etc.)

- Cost budget and production volume

- Processing technology requirements

Q3: How to ensure dimensional accuracy of plastic molded parts?

- Precision mold design and manufacturing (±0.01mm accuracy)

- Strict process parameter control (temperature, pressure, time)

- Advanced testing equipment (coordinate measuring machine)

- Continuous process monitoring and adjustments

Q4: What is the typical tolerance range for plastic molded parts?

- Standard precision: ±0.1mm

- Medium precision: ±0.05mm

- High precision: ±0.02mm

- Ultra-high precision: ±0.01mm

Q5: What are the environmental requirements and development trends in plastic molding?

- EU imposes high tariffs on plastic packaging with recycled content below 30%

- California SB 54 mandates 65% packaging recycling rate by 2032

- China’s “14th Five-Year Plan” plastic pollution control action completely bans non-degradable single-use products

- Recycled plastic penetration rate increasing from 22% in 2023 to over 35% by 2028

- Rapid growth in bio-based and biodegradable plastic applications

- Establishment of circular economy models