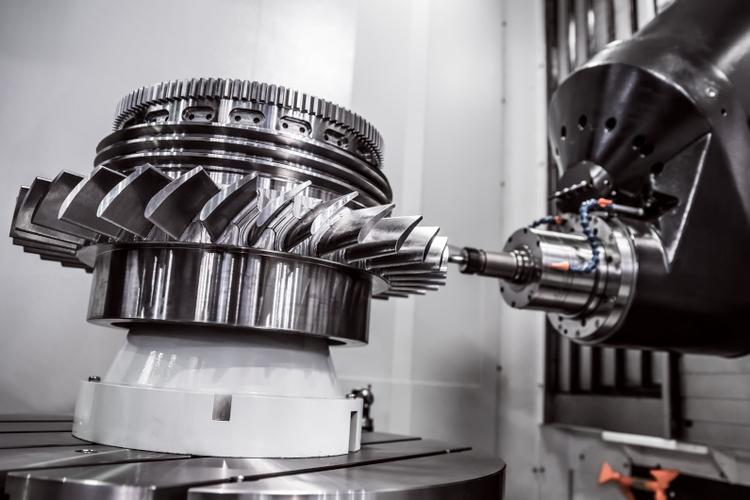

Metal polishing is a process of treating the metal surface through mechanical, chemical, or electrochemical means to improve its surface finish, remove machining marks and burrs, or give it a more decorative appearance. In an era where precision machining and product appearance are increasingly valued, polishing has become a crucial process in many industries.

Why CNC Metal Polishing?

During the CNC machining process, the surface roughness of parts is not randomly generated but is controlled according to different application requirements. Different usage scenarios have different requirements for the surface roughness of parts to ensure assembly accuracy, functional performance, and service life. Through precision grinding and polishing, an excellent surface roughness can be obtained, which is particularly suitable for applications with high requirements for surface finish.

Advantages of CNC Metal Polishing

Metal polishing has multiple advantages in the metal processing process. It not only improves the appearance of products but also enhances their performance and durability. The following are several common benefits of metal polishing:

Enhance Product Aesthetics

Generally, the surface of machined metal parts is not smooth and often has a rough texture and machining marks. The polishing process uses tools such as grinding wheels to remove surface scratches, defects, oxide layers, and small indentations, making the metal surface more flat, smooth, and mirror – like, thus significantly improving the appearance quality.

However, the higher the appearance requirements of the product, the more time and cost are required for processing.

Form a Protective Layer

Metal polishing is not just for looks. For example, the polishing of titanium alloy not only improves its surface quality but also enhances its oxidation and corrosion resistance. The polished metal surface forms a dense, reflective protective layer, which helps to delay wear and corrosion and extend the service life of the parts.

Enhance Light Reflection Performance

The polished metal surface has a stronger light – reflecting ability, presenting a brighter and more vivid visual effect. This feature is particularly important in occasions where a high – reflection effect is required, such as in architectural decoration, jewelry, lighting fixtures, and other high – end visual products.

Improve Functional Performance

In some application scenarios, polishing also helps to improve the actual functional performance of metal parts. For example, in precision instruments and mechanical components, polishing can remove small surface defects, making the part surface more uniform, which helps to reduce friction, improve motion efficiency, enhance electrical conductivity, and thus improve the overall performance of the equipment.

Improve Cleanliness

The polished metal surface is smooth and pore – free, making it less likely to accumulate dirt and bacteria, effectively reducing the risk of contamination. It is easier to clean and maintain compared to an unpolished surface, which helps to improve work efficiency. In addition, the flat surface reduces the dependence on chemicals during the cleaning process, avoiding secondary damage to the metal by corrosive cleaners.

Types of CNC Metal Polishing Technologies

Electrolytic Polishing: It is the anodic erosion of metal parts under specific conditions. The surface quality of electrolytic polishing is good, the solution is stable, and no harmful gases are generated. It has a much better effect than ordinary polishing and liquid polishing; the workpiece will not rust.

Magnetic Abrasive Polishing: Magnetic abrasive polishing uses magnetic abrasives to form an abrasive brush under the action of a magnetic field to grind the workpiece. This method has high processing efficiency, good quality, easy – to – control processing conditions, and good working conditions.

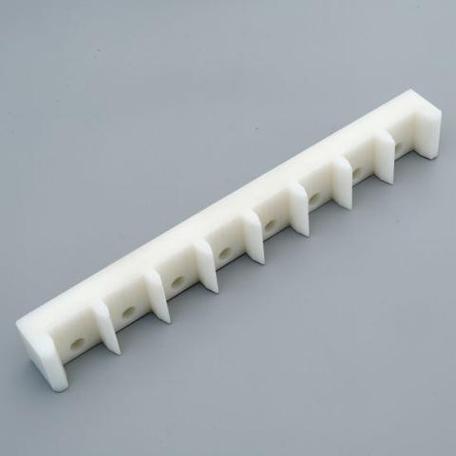

Mechanical Polishing: Tools such as mechanical polishing wheels, brushes, and abrasive cloth are used to polish the metal surface. This method requires the use of abrasives, has a low cost, but the surface roughness after polishing is relatively poor.

Chemical Polishing: Chemical reagents are used to chemically corrode the metal surface to achieve a polishing effect. This method is easy to operate and has a low cost, but it may cause environmental pollution.

Electrochemical Polishing: Based on the electrolysis principle, polishing is achieved by forming a thin metal anodic oxide film on the metal surface. This method has a good polishing effect and does not pollute the environment, but the cost is high.

Ultrasonic Polishing: Using the vibration of ultrasonic waves, abrasives are used to grind and polish the surface of the workpiece. This method is suitable for workpieces with complex shapes and can achieve automated operation, but the equipment cost is high.

Fluid Polishing: High – speed flowing liquid and the abrasives it carries are used to wash the surface of the workpiece to achieve polishing. This method is suitable for the polishing of large workpieces and precision parts, but it requires the use of expensive abrasives and liquids.

How to Polish CNC Metal to a Mirror Finish?

Mirror polishing is a polishing process that makes the product surface present a mirror – like effect. Mirror polishing requires multiple rounds of grinding and polishing, and the surface roughness of the product workpiece should reach above grade 12. The mirror – polishing process uses polishing sandpapers with different roughness levels to grind step by step, and a flexible polishing tool and abrasives or other polishing media are used to modify the surface of the workpiece.

The order of mirror polishing must not be messed up. You cannot start with fine sandpaper. Fine sandpaper is not used to remove rough tool marks. The surface of the workpiece polished with fine sandpaper may look shiny, but upon closer inspection, many rough textures can still be seen on the surface. The correct order should be to first use an oilstone to remove the rough textures, then use fine sandpaper for grinding, and finally use polishing paste or grinding paste for fine polishing to achieve a mirror – like effect.

To obtain a good mirror – like effect, it is necessary to carefully select high – quality polishing tools such as oilstones and sandpapers, so that the mirror – like effect can be greatly improved.

Key Points to Note During CNC Metal Polishing:

Cleaning

a. Do not polish the mold near an environment where dust may be generated.

b. The polisher must keep himself and the working area clean.

c. Place oilstones of different grit numbers separately.

d. Use one piece of polishing tool with only one grit number of diamond paste.

e. Thoroughly clean the mold parts before and after each process.

Observation

a. Work under good lighting.

b. Carefully observe and inspect the polished surface before each polishing process.

c. Before the next process, check and confirm that all the grinding marks of the previous process have been completely removed.

d. Pay attention to new grinding marks.

Cross – Polishing

a. Make sure the polisher knows that all the grinding and polishing marks of the previous process have been completely removed before moving on to the next process.

b. Maintain good flatness of the mold surface.

c. Avoid and reduce the indentation at the corners and edges of the mold surface.

d. Drawing polishing

e. The final polishing direction should be consistent with the demolding direction of the mold parts.

f. This method enables the polisher to polish in the demolding direction of the mold (so that the product can be ejected smoothly).