Answer

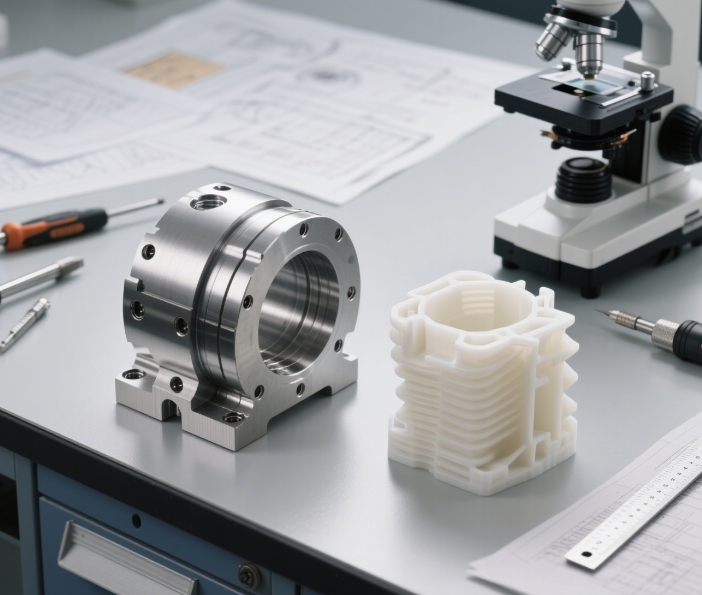

Whether CNC is faster than 3D printing depends on the scenario: CNC is generally faster for mass-producing simple parts, while 3D printing may excel in single-piece production of complex structures or prototypes.

Extended Response

I. Core Impact of Process Principles on Speed

1. CNC (Subtractive Manufacturing) Speed Logic

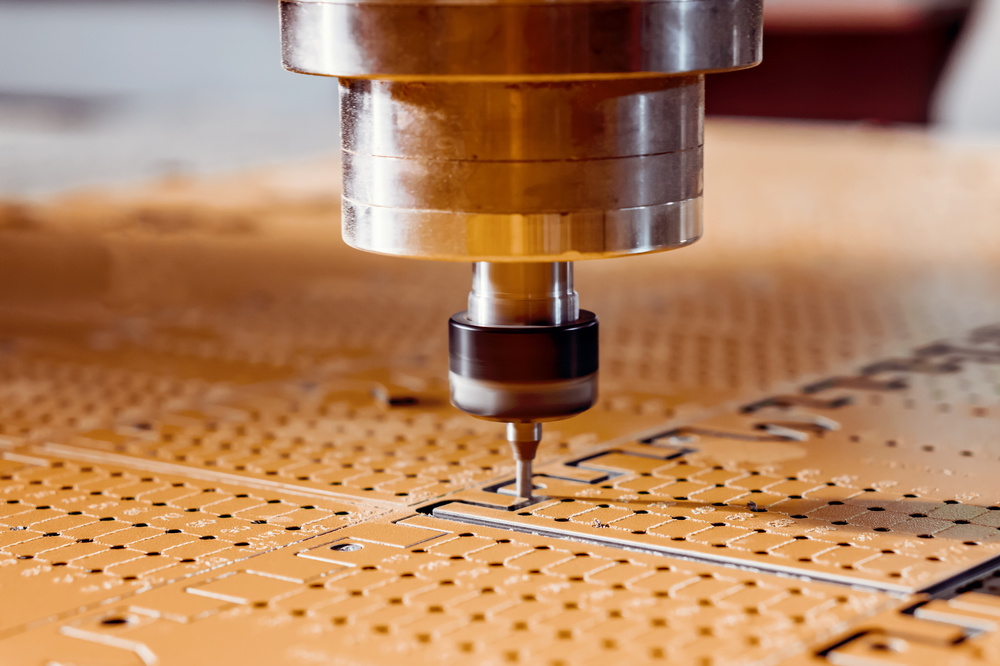

- Principle: Removes material via tool cutting, with speed determined by cutting efficiency (spindle speed, feed rate) and process steps.

- Advantage: Rapid for regular-shaped parts with moderate-hardness materials (e.g., aluminum, plastic). For example, CNC can turn an aluminum cylinder in minutes, while 3D printing takes longer for layer-by-layer deposition.

- Limitation: Complex surfaces or internal structures require multi-axis machining and split processes (milling, drilling, tapping), increasing total time.

2. 3D Printing (Additive Manufacturing) Speed Logic

- Principle: Forms parts by layer-by-layer material deposition (e.g., FDM, SLS), affected by layer thickness, printing precision, and equipment power.

- Advantage: Single-piece production of complex structures (hollows, internal channels) without process splitting. For instance, 3D printing a mold with complex cooling channels takes hours, while CNC needs days of multi-step cutting + EDM.

- Limitation: Mass production requires sequential printing or multiple machines, with time increasing linearly with quantity; high-precision printing (e.g., 0.05mm layer thickness) is slow per layer.

II. Production Flow and Batch Efficiency

1. Mass Production: CNC’s “Scale Effect”

- Process: Programming → clamping → batch machining (short changeover time), ideal for batches >100.

- Example: Producing 100 copper parts via CNC: 5 min/part with multi-piece clamping, totaling ~10 hours (including changeover). 3D printing 1 part takes 2 hours, 100 parts take 200 hours—significant efficiency gap.

- Trade-off: Requires dedicated fixtures (hours to days of prep), but speed prevails once operational.

2. Low-Volume/Single-Piece: 3D Printing’s “Flexibility”

- Process: Modeling → slicing → printing (no fixtures needed), perfect for 1–10 prototypes or custom parts.

- Example: During design iteration, 3D printing a revised model takes hours, while CNC needs reprogramming and reclamping (1–2 days), especially for frequent design changes.

III. Influence of Material and Structural Complexity

1. Material-Driven Speed Differences

- CNC’s Material Adaptability:

- Metals (steel, aluminum): Fast cutting, but hard materials (titanium) require reduced speed.

- Plastics/woods: Extremely fast—e.g., ABS plastic CNC machining in minutes.

- 3D Printing’s Material Constraints:

- Plastics (PLA, ABS): Faster printing (0.2mm layer thickness, mm-level height per hour).

- Metals (stainless steel, titanium): Slow laser sintering (0.5–1mm height per hour).

- Example: 3D printing a 10cm stainless steel part via SLS takes 20–30 hours, while CNC milling takes hours (moderate material removal).

2. Structural Complexity’s “Time Reversal”

- CNC’s Edge in Simple Structures:

- Regular shapes (cubes, cylinders): Fewer processes, fast cutting.

- Example: CNC milling an aluminum plate takes 10 min; 3D printing takes 1–2 hours.

- 3D Printing’s Edge in Complex Structures:

- Hollows, bionic designs, internal channels: No tool accessibility issues, one-step forming.

- Example: 3D printing a ceramic part with spiral inner holes via DLP takes 6 hours; CNC needs split processing + assembly, >24 hours.

IV. Hidden Impact of Post-Processing Time

1. CNC Post-Processing

- Typically involves deburring, cleaning, surface treatment (anodizing), taking minutes to hours.

- Example: Aluminum CNC part post-processing: ~0.5 hours; 3D printed metal parts may spend 30–50% of total time on post-processing.

2. 3D Printing Post-Processing

- Support removal: Manual or chemical dissolution for complex structures (hours for FDM plastics).

- Curing/sintering: Metal 3D prints need high-temperature sintering or HIP (10–20 hours).

- Surface treatment: Rough 3D printed surfaces require polishing, electroplating, adding time.

- Example: SLS-printed nylon part post-processing (de-powdering, polishing): 4–6 hours vs. 1 hour for CNC.

V. Equipment and Manpower Efficiency

1. CNC Equipment Utilization

- Single CNC machine can continuously process batches with minimal human intervention, suitable for 24/7 unmanned production.

- Example: CNC can automatically machine 100 parts overnight, while 3D printers may need manual intervention for material replacement or cooling.

2. 3D Printer Limitations

- Single machine prints 1–several parts (depending on build size), hard to adjust tasks mid-process.

- Example: Producing 50 different parts via 3D printing requires 50 separate tasks, far longer than CNC batch programming.

VI. Speed Comparison Cases

| Application Scenario | CNC Time | 3D Printing Time | Speed Difference Reason |

|---|---|---|---|

| Mass-produce 100 aluminum gears (module 2, Φ50mm) | ~8 hours (with fixtures) | ~150 hours (single machine) | CNC’s high batch changeover efficiency |

| Single-piece titanium orthopedic implant (complex surface) | ~24 hours (multi-axis) | ~12 hours (SLM printing) | 3D printing’s one-step forming without process splits |

| Rapid prototyping (ABS plastic, 100×100×50mm) | ~2 hours (milling) | ~3 hours (FDM printing) | CNC slightly faster for simple structures, but 3D printing skips fixturing |

| Manufacture injection mold with internal channels (steel) | ~3 days (milling + EDM) | ~1 day (SLM printing) | 3D printing eliminates EDM process, saving time |

VII. Conclusion: Process Selection for Optimal Speed

- Choose CNC for:

- Batches ≥50, regular structures, metal/hard plastic materials.

- Tight dimensional control (tolerance ±0.01mm) with sensitive post-processing time.

- Choose 3D printing for:

- Low-volume/single-piece (≤10), complex structures (hollows, internal holes, bionic designs).

- Rapid iteration in product development, or special composites (e.g., carbon fiber reinforced plastics).

- Hybrid process optimization:

- Combine “3D printing + CNC finishing”: 3D print complex structures, then CNC machine surfaces to high precision, balancing speed and accuracy.

Final Advice: Speed comparison depends on part quantity, structural complexity, material, and precision requirements—no absolute superiority. Choose the process based on specific needs.