Answer

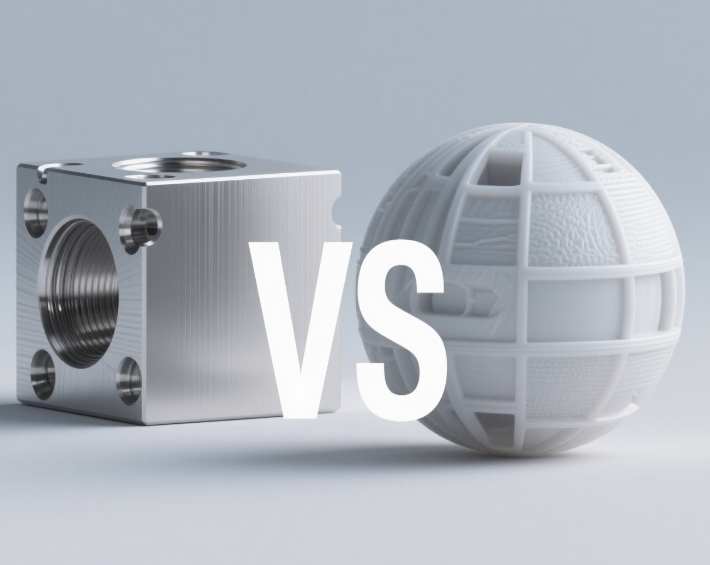

There is no absolute answer to whether CNC machining is superior to 3D printing. The advantages and disadvantages of the two depend on the requirements of specific application scenarios, such as material properties, part complexity, precision requirements, production volume, cost budget, etc. CNC machining has more advantages in mass production, high – strength materials, and high – precision parts, while 3D printing is more competitive in complex structures, customization, and rapid prototyping.

Extended Answer (Comparative Introduction Point by Point)

I. Core Differences in Technical Principles and Manufacturing Methods

CNC Machining (Subtractive Manufacturing)

Principle: The numerical control system controls the tool to perform subtractive processing such as cutting, milling, and drilling on raw materials (such as metals, plastics, wood, etc.), gradually removing materials to form parts.

Characteristics: It relies on a pre – designed CAD model. There is significant material loss during the processing, but the dimensional control is precise. It is suitable for parts with regular geometric shapes or symmetrical structures.

3D Printing (Additive Manufacturing)

Principle: Based on the principle of layer – by – layer stacking, materials (powders, filaments, liquids, etc.) are solidified layer by layer through laser, hot – melting, etc., “growing” parts from scratch.

Characteristics: It does not require tools and molds and can be directly manufactured according to the digital model. It is suitable for designs with complex curved surfaces, hollow structures, or internal channels that are difficult to achieve with traditional processes.

II. Comparison of Material Selection and Performance

Material Adaptability of CNC Machining

Advantageous Materials:

Metallic Materials: High – strength materials such as aluminum alloys, steel, and titanium alloys. Dense microstructures can be obtained through cutting to meet mechanical property requirements (such as aerospace parts).

Engineering Plastics: Acrylic, nylon, etc. After processing, the surface is smooth, which is suitable for high – precision mechanical components.

Limitations: Materials with too high hardness (such as tungsten steel) may wear the tool. For complex structures, multiple clampings are required, reducing processing efficiency.

Material Development and Limitations of 3D Printing

Mainstream Materials:

Plastics: PLA, ABS, nylon, etc., are suitable for prototype verification but have relatively low strength.

Metals: Stainless steel, titanium alloy, aluminum alloy, etc. (require metal 3D printers). However, the material cost is high, and heat treatment may be required after printing to eliminate internal stress.

Special Materials: Ceramics, biological materials (such as hydroxyapatite for bone implants), composite materials, etc., expanding customized application scenarios.

Limitations: The types of materials are still fewer than those of CNC. The mechanical properties (such as ductility) of some metal printed parts are inferior to forged or machined parts, and there may be small pores inside.

III. Precision, Surface Quality, and Detail Performance

Precision Advantages of CNC Machining

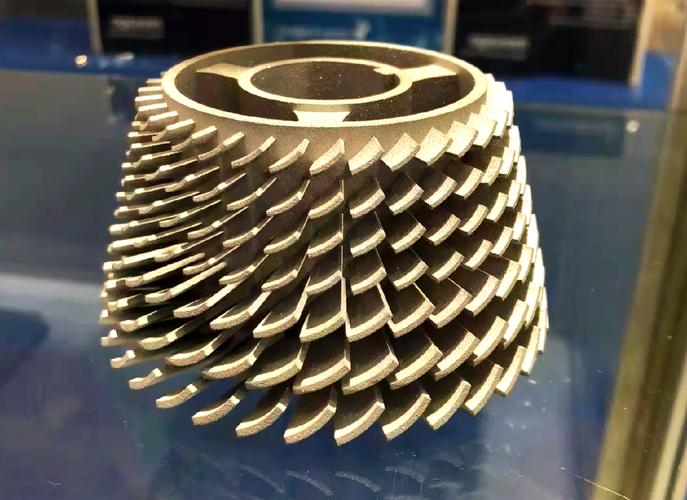

Precision Range: Usually, it can reach ±0.01 – 0.1mm. High – end equipment (such as five – axis CNC) can achieve micron – level precision, which is suitable for high – precision requirements in aerospace, medical equipment, etc. (such as engine blades, precision gears).

Surface Quality: Through post – treatments such as polishing and electroplating, the surface roughness can be reduced to less than Ra0.8μm, meeting mirror – finish or fit – tolerance requirements.

Precision Bottlenecks and Improvements of 3D Printing

Precision Range: The precision of ordinary FDM (Fused Deposition Modeling) is about ±0.1 – 0.5mm, and SLS (Selective Laser Sintering) or metal 3D printing can reach ±0.05 – 0.1mm, but it is still lower than high – end CNC.

Surface Quality: Layer – by – layer stacking leaves obvious lines. Post – treatments (such as sanding, vapor smoothing) are required to improve it, but it is difficult to process the inside of complex structures. The surface roughness is usually between Ra1.6 – 12.5μm.

Detail Advantages: It can print thin – walled structures, hollow structures, or nested components (such as integrated gear sets) with a thickness of less than 0.1mm, which is difficult for CNC to achieve due to tool size limitations.

IV. Comparison of Production Efficiency and Batch Cost

CNC Machining: Suitable for Batch and Standardized Production

Efficiency Characteristics:

For single – piece production, there are high time – costs for pre – processing such as programming, clamping, and tool setting. However, in batch production, only the program needs to be repeated when changing workpieces, and the efficiency is significantly improved (such as mass production of automotive parts).

The processing speed depends on the material hardness and tool performance. The metal cutting speed can reach tens of meters per minute.

Cost Model:

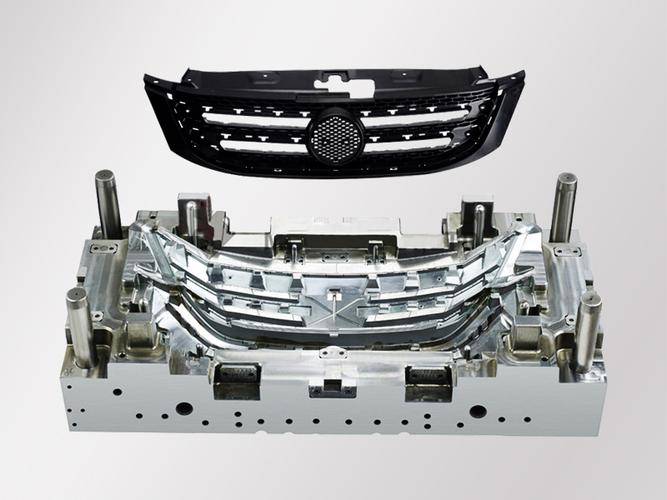

The upfront investment is high (equipment, tools, molds), but the unit cost decreases as the quantity increases in batch production, which is suitable for large – scale production of more than 100 pieces.

3D Printing: Suitable for Small – batch and Customized Production

Efficiency Characteristics:

No molds are required, and it goes directly from the digital model to the entity. The single – piece production cycle is short (from a few hours to a few days), which is suitable for rapid iteration (such as product prototype making).

In batch production, parts need to be printed one by one or in parallel with multiple workstations. The efficiency improvement is limited, and printing large parts may take dozens of hours.

Cost Model:

The upfront equipment cost is moderate (the cost of desktop 3D printers is lower than that of CNC), but the material cost is high (such as the price of metal powder is several times that of traditional sheets). And the printing time is calculated by volume. The cost is lower for small – batches (1 – 10 pieces), and CNC is more cost – effective when the quantity exceeds 50 pieces.

V. Differentiated Choices of Application Scenarios

Typical Applications of CNC Machining

Industrial Manufacturing: Automotive engine blocks, aircraft frame parts, medical device housings, etc., where high – strength, high – precision, and mass production are required.

Mold Manufacturing: Cores and cavities of injection molds and die – casting molds, parts that require wear – resistance and precise dimensions.

Precision Parts: Watch gears, optical instrument brackets, etc., products with extremely high requirements for surface finish and fit precision.

Typical Applications of 3D Printing

Prototype Design: Rapid sample making in the product development stage, facilitating the testing of structure and appearance (such as consumer electronics casings, toy models).

Complex Structure Manufacturing: Hollow turbine blades in the aerospace field, personalized dentures or orthopedic implants in the medical field (customized according to patient CT data).

Small – batch Customization: Art sculptures, customized medical devices, racing car parts (such as lightweight carbon – fiber brackets), etc., scenarios with personalized demands and small quantities.

VI. Technical Limitations and Complementarity

Limitations of CNC

It is difficult to process internal complex channels (such as vascular – like structures). Parts need to be disassembled and assembled, increasing the process complexity.

The material utilization rate is low. Machining large parts may waste more than 70% of the material (such as aluminum alloy aerospace parts).

Limitations of 3D Printing

Large – scale parts may warp and deform during printing, and the size is limited by the equipment’s forming chamber (for example, desktop 3D printers can usually only print parts within 300mm×300mm×300mm).

The mechanical properties are weak in some directions (such as the inter – layer joints), which is not suitable for key components that bear high loads.

Examples of Technical Complementation

Hybrid Manufacturing: First, use 3D printing to make blanks with complex structures, and then perform surface finishing through CNC, taking into account both precision and efficiency (such as the inner lining of aerospace engine combustion chambers).

Rapid Tooling: Use 3D printing to make silicone molds or resin molds, and then process metal parts through CNC, reducing the mold cost for small – batch production.

VII. How to Choose: Key Decision – making Factors

Part Complexity:

Complex curved surfaces, hollow structures, internal channels: 3D printing is preferred.

Regular geometric shapes, symmetrical structures: CNC is preferred.

Production Quantity:

1 – 10 pieces: 3D printing is more cost – effective.

More than 100 pieces: CNC is more economical for batch production.

Material and Performance Requirements:

High – strength metals, dense structures: CNC (such as aluminum alloy 6061 – T6).

Special materials or lightweight designs (such as porous structures): 3D printing (such as titanium alloy powder – bed fusion).

Time and Cost Balance:

Emergency prototypes or customized parts: 3D printing (no need to wait for molds).

Mass production with sufficient budget: CNC (lower long – term cost).

VIII. Future Trends: Integration and Innovation

Technology Integration: Composite machine tools that combine CNC and 3D printing (such as the Mazak INTEGREX i – 400 AM) have achieved the integration of additive and subtractive processing, improving the manufacturing efficiency of complex parts.

Material Breakthroughs: The performance of 3D – printed metal materials is gradually approaching that of forged materials (such as the strength improvement of GE’s LEAP engine fuel nozzle through 3D printing), and CNC is also exploring processing techniques for harder and more brittle materials (such as diamond – tool cutting of ceramics).

Summary: The comparison between CNC machining and 3D printing is not about “superiority or inferiority,” but a choice of “suitability.” The former is the mainstay of industrial large – scale production, while the latter is the catalyst for innovative design and customized manufacturing. The future development of the manufacturing industry depends more on the collaborative application of the two to meet the full – range of needs from high – precision mass production to extreme personalization.