CNC machining is neither universally easy nor impossibly difficult—its complexity depends on the scope of work, your skill level, and the tools involved.

Why might it seem accessible for beginners?

For basic tasks, CNC machining can feel approachable:

- User-friendly software: Modern CAM (Computer-Aided Manufacturing) programs (e.g., Fusion 360, Mastercam) automate much of the G-code generation, letting users design parts in 3D and convert them into machine instructions with minimal manual coding.

- Simplified setups: Many entry-level CNC machines (e.g., desktop mills or lathes) come with preconfigured toolpaths and safety features, reducing the risk of errors for newcomers.

- Foundational logic: Basic operations like drilling a hole or cutting a straight line rely on simple G-code commands (e.g., G01 for linear movement), which can be learned quickly.

When does CNC machining become challenging?

Advanced applications demand deeper expertise:

- Complex geometries: Machining curved surfaces, 5-axis movements, or tight-tolerance parts (e.g., aerospace components) requires mastery of CAM software, toolpath optimization, and material science (e.g., understanding how metals deform under cutting forces).

- Troubleshooting: Issues like tool wear, vibration, or inaccurate measurements often stem from subtle factors—such as feed rate miscalculations or spindle alignment errors—that require experience to diagnose.

- Programming nuances: While CAM automates much of G-code, customizing cycles (e.g., peck drilling for deep holes) or adapting to proprietary machine features (e.g., Fanuc vs. Haas controllers) demands familiarity with advanced G/M-code logic.

Key factors in mastering CNC machining

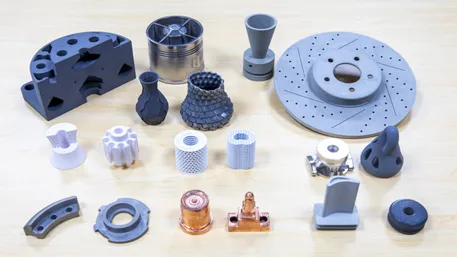

- Practice: Hands-on experience with different materials (wood, plastic, metal) and machine types builds intuition for how tools interact with workpieces.

- Cross-discipline knowledge: Understanding CAD design, engineering drawings (GD&T), and machining physics (e.g., chip evacuation) is critical for consistent results.

- Adaptability: New technologies (e.g., AI-driven toolpath optimization or additive-subtractive hybrid machines) require continuous learning.

In short, CNC machining is easy to start with for basic projects but grows increasingly complex as you tackle precision, complexity, or specialized applications. With practice and targeted learning, however, its challenges become manageable.