1、Answer

No, CNC (Computer Numerical Control) is not limited to metal. It can machine a wide range of materials, including plastics (e.g., ABS, PEEK), woods (hardwoods, composites), foams (polystyrene, urethane), ceramics, graphite, composites (carbon fiber, fiberglass), and even soft materials like wax or rubber. The versatility depends on the machine’s design and tooling.

2、Expansion

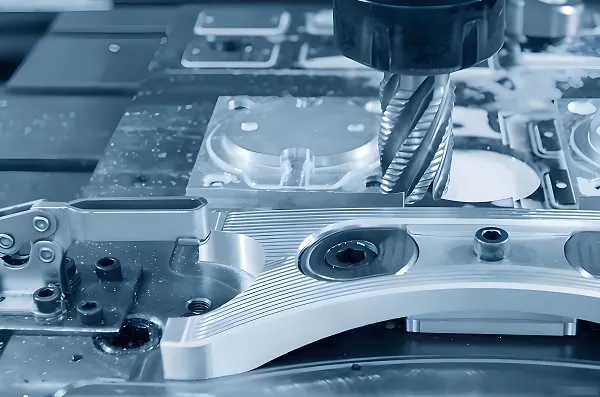

Diverse Materials Machined by CNC

-

Plastics

- Common Types: Acrylic (Plexiglas), polycarbonate, nylon, and engineering plastics like PEEK (used in aerospace/medical).

- Applications: Prototyping parts (e.g., 3D-printed drone casings), machine components (gears, bearings), and optical components (acrylic lenses).

- Advantages: Low cost, ease of machining (requires lower cutting forces than metal), and minimal tool wear. For example, a CNC router can cut intricate acrylic signage with smooth edges in minutes.

-

Wood and Composites

- Materials: Hardwoods (oak, maple), plywood, MDF, and wood-composite boards.

- Applications: Furniture (custom cabinetry, intricate carvings), musical instruments (guitar bodies), and architectural models.

- Example: A 3-axis CNC router can carve a detailed wooden door panel with 0.5 mm precision, replicating designs that would take hours by hand.

-

Foams and Soft Materials

- Types: Polystyrene (Styrofoam), urethane foam, and wax.

- Uses: Prototyping (e.g., foam models for automotive design), mold making (wax patterns for investment casting), and art installations.

- Speed: CNC hot wire cutters can slice through 500 mm-thick foam blocks in seconds, creating smooth curves for surfboard cores or stage props.

-

Ceramics and Graphite

- Ceramics: Machined using diamond-tipped tools for high-temperature applications (e.g., kiln components, semiconductor fixtures).

- Graphite: Used in CNC for electrode machining (EDM) in mold making and lithium-ion battery manufacturing.

- Challenge: Brittle materials require precise feeds/speeds to avoid cracking. A CNC mill with a 0.1 mm end mill can drill micro-holes in ceramic substrates for electronics.

-

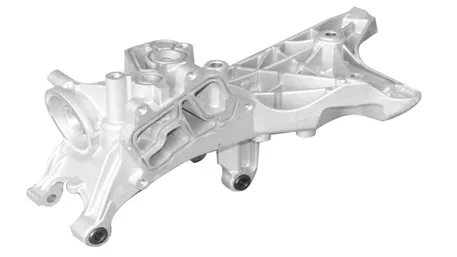

Composites (Fiberglass/Carbon Fiber)

- Applications: Aerospace panels, sports equipment (golf club heads, bicycle frames), and marine components.

- Tooling: Specialized carbide or diamond-coated tools prevent delamination. A 5-axis CNC can machine a carbon fiber wing section with integrated ribs in one setup, reducing assembly steps.

Why Material Diversity Matters

- Prototyping Flexibility: Engineers can test designs in plastic or wood before committing to expensive metals, saving time and cost. For example, a startup might use CNC-machined nylon to validate a gear design before producing it in steel.

- Art and Customization: Artists and designers use CNC to craft unique pieces from unconventional materials. A woodworker might combine CNC-carved walnut with acrylic inserts for one-of-a-kind furniture.

- Industrial Versatility: In manufacturing, CNC machines often switch between materials in a single production line. A shop might machine aluminum brackets in the morning and switch to cutting PVC pipes for plumbing fixtures in the afternoon.

Limitations: While CNC handles many materials, extremely hard substances (e.g., diamond) or highly abrasive composites may require specialized machines or processes (e.g., waterjet cutting). Overall, CNC’s adaptability makes it a cornerstone in industries far beyond metalworking, from rapid prototyping to artistic fabrication.