Answer

CNC (Computer Numerical Control) is not limited to metal processing. It can precisely machine various materials, including plastics, woods, composites, ceramics, foams, stones, etc., covering multiple fields such as manufacturing, aerospace, medical, and art design.

Extended Response

I. Basic Concepts and Core Principles of CNC Machining

CNC (Computer Numerical Control) refers to automated precise machining controlled by digital programs, dictating the motion trajectories and processing parameters of machine tools. Its core advantages include:

- Programmability: G-code, M-code, and other instructions control toolpaths to adapt to different materials.

- High Precision and Consistency: Achieves accuracy up to 0.01mm with strong repeatability, unaffected by manual operation fluctuations.

- Multi-Functional Integration: Integrates milling, drilling, turning, cutting, and other processes in one device.

II. Non-Metallic Materials Processed by CNC and Applications

(1) Plastics: Lightweight and Diverse

- Common Materials:

- ABS, PVC, Acrylic (PMMA): Moderate hardness, easy to cut, used for models, casings (e.g., electronic product housings), and billboards.

- Nylon (PA), Polyoxymethylene (POM): Wear-resistant and chemical-resistant, suitable for mechanical parts (gears, bearings) and medical device components.

- Polycarbonate (PC): High transparency and impact resistance for optical elements and protective masks.

- Processing Features:

- Control cutting temperature (plastics soften easily), use high-speed steel or ceramic tools, and cool with air or water.

- Achieve surface textures (matte, mirror effects) via CNC engraving or assist with thermoforming.

(2) Woods and Wood Composites: Digital Upgrades of Traditional Crafts

- Common Materials:

- Hardwoods (oak, walnut): For furniture parts and crafts (carved door panels, musical instrument bodies).

- Softwoods (pine, fir): Suitable for architectural models and decorative trims.

- Plywood, MDF: Low cost, used for mass-produced furniture components (drawer panels, cabinets).

- Processing Features:

- Adjust cutting direction according to wood grain (顺着纹理加工更光滑) and use spiral-edge tools to reduce chipping.

- Combine with CNC engraving for complex patterns (reliefs, hollow designs), far more efficient than manual work.

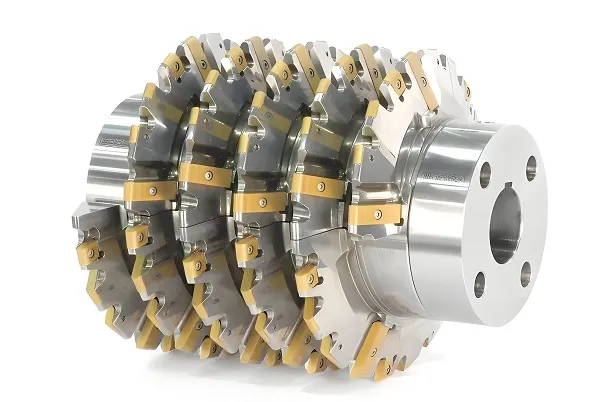

(3) Composites: Preferred for High Performance

- Common Materials:

- Carbon Fiber Composites: Lightweight and high-strength, used for aerospace components (aircraft wing panels), racing car bodies, and sports equipment (golf clubs).

- Fiberglass-Reinforced Plastic (FRP): Good insulation for electrical housings and marine components.

- Epoxy-Based Composites: Corrosion-resistant, suitable for chemical equipment and pipe fittings.

- Processing Challenges:

- Fibers are prone to delamination; use diamond-coated tools and low speed with high feed to reduce tearing.

- Dust is irritating, requiring dedicated dust collection systems.

(4) Ceramics and Stones: Precision Machining of Hard-Brittle Materials

- Common Materials:

- Engineering Ceramics (alumina, silicon nitride): High-temperature and wear-resistant, for semiconductor parts and mechanical seals.

- Natural Stones (marble, granite): Architectural decoration (countertops, reliefs) and tombstone engraving.

- Artificial Stones (quartz): Kitchen countertops and bathroom products.

- Technical Points:

- Use diamond grinding wheels or laser cutting, and feed minimally to avoid material cracking.

- Strictly control temperature for ceramics (prevent thermal stress cracking) and use cooling water for stones to reduce tool wear.

(5) Foams and Soft Materials: Rapid Prototyping

- Common Materials:

- Polystyrene (EPS), Polyurethane Foam: Low density, used for mold prototypes (e.g., automotive panel molds) and packaging.

- Rubber, Silicone: Elastic materials, milled into seals and shock pads via CNC.

- Processing Advantages:

- Minimal tool wear, high-speed cutting suitable for large-scale models (exhibition props, movie sets).

- Some foams combine hot wire cutting with CNC for curved shapes.

III. Typical Application Fields of CNC in Non-Metallic Material Processing

(1) Manufacturing and Industrial Production

- Automotive: CNC-machined plastic interior parts (dashboard housings), carbon fiber engine components, foam molds.

- Electronics: PCB cutting, plastic connector machining, aluminum heat sink milling (though metal is involved, non-metals are applied simultaneously).

- Medical Devices: Nylon implant prototypes, acrylic surgical instrument trays, PEEK medical parts.

(2) Aerospace and High-End Manufacturing

- Carbon fiber composite fuselage components (e.g., Boeing 787 composite wings).

- Ceramic Matrix Composite (CMC) turbine blade machining, requiring CNC with laser precision engraving.

(3) Art Design and Cultural Innovation

- Wood carving (Chinese furniture carvings), acrylic artwork cutting, stone relief production.

- Integration of 3D printing and CNC: Prototype via 3D printing, then fine surface processing via CNC.

(4) Construction and Home Furnishing

- Custom wooden furniture parts (irregular table legs, carved partitions).

- Seamless splicing of quartz kitchen countertops, marble tile engraving.

IV. Technical Differences and Equipment Selection for CNC Processing of Different Materials

(1) Tool and Cutting Parameter Comparison

| Material Type | Common Tools | Cutting Speed Range | Feed Rate Suggestion | Cooling Method |

|---|---|---|---|---|

| Aluminum Alloy | Carbide Coated Tools | 100–300m/min | 0.1–0.5mm/rev | Emulsions or Air Cool |

| ABS Plastic | HSS or PCD Tools | 50–150m/min | 0.05–0.2mm/rev | Air Cooling |

| Carbon Fiber | Diamond-Coated Tools | 20–50m/min | 0.02–0.1mm/rev | Dry Cutting or MQL |

| Marble | Diamond Grinding Wheels | 5–10m/s | 0.1–0.3mm/rev | Water Cooling |

(2) Equipment Types and Suitable Scenarios

- CNC Milling Machines/Machining Centers: Universal, suitable for milling and drilling of metals and non-metals.

- CNC Engraving Machines: High spindle speed (20,000–40,000rpm), ideal for fine engraving of wood, plastic, and stone.

- 5-Axis CNC Machines: For complex surface machining (e.g., aerospace composite components), requiring multi-axis 联动 control.

- Laser CNC Equipment: Suitable for cutting films, foams, acrylics, with small heat-affected zones.

V. Advantages and Challenges of CNC Processing Non-Metallic Materials

(1) Core Advantages

- Flexible Production: Switch between material programs on the same device, adapting to low-volume customization (e.g., personalized cultural products).

- High-Precision Complex Shapes: Achieve curves, hollows, and microstructures difficult for traditional crafts (e.g., micrometer-scale textures on phone cases).

- Productivity Improvement: Compared to manual work, CNC operates 24/7, reducing labor costs (e.g., mass-producing carved furniture parts).

(2) Challenges

- Process Complexity Due to Material Diversity: Different materials require dedicated tools and parameters, increasing debugging costs.

- Environmental and Safety Issues: Dust from carbon fiber/ceramic processing needs special handling; plastic processing may release harmful gases.

- High Equipment Investment: High-precision 5-axis CNC machines are expensive (millions to tens of millions), limiting adoption by SMEs.

VI. Future Trends: Integration of CNC and Multi-Material Processing

- Hybrid Processing Technologies: CNC equipment integrates milling, laser cutting, 3D printing, etc., enabling integrated processing of metals and non-metals.

- Intelligence and Automation: Optimize processing parameters for different materials via AI algorithms, reducing manual debugging (e.g., FANUC’s AI tool wear detection system).

- Green Processing: Promote dry cutting and cryogenic cutting to reduce energy consumption and pollution in non-metallic material processing (e.g., liquid nitrogen cooling for ceramics).

Conclusion

The essence of CNC technology is precise machining through digital control, with applications long beyond metal materials. From plastics to ceramics, woods to composites, CNC has become core to multi-material processing, leveraging programmability and high precision. In the future, with the integration of materials science and CNC technology, its applications in non-metallic material processing will expand, driving manufacturing toward flexibility and intelligence.