Step 1: First, Define “Strength” for Die Casting

- Tensile Strength: The maximum force a part can withstand before breaking (measured in MPa or psi). Critical for load-bearing parts (e.g., automotive brackets).

- Yield Strength: The force that causes permanent deformation (e.g., bending). Important for parts that need to retain shape under stress (e.g., tool handles).

- Impact Strength: Resistance to sudden shocks (e.g., drops or collisions). Key for consumer products (e.g., power tool housings) or automotive parts.

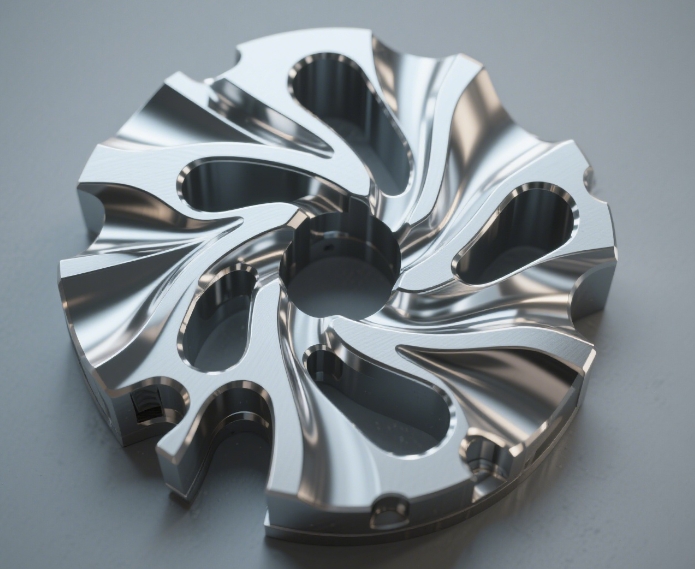

- Fatigue Strength: Resistance to repeated stress (e.g., vibration). Essential for parts like engine mounts or pump impellers that operate long-term.

Step 2: How Alloy Choice Determines Die Casting Strength

|

Alloy Type

|

Tensile Strength

|

Yield Strength

|

Impact Strength

|

Key Strength Traits

|

Typical Strong Applications

|

|

Zinc (Zamak 5)

|

320 MPa (46,400 psi)

|

230 MPa (33,400 psi)

|

35 J/m² (25 ft-lb/in²)

|

Balanced strength + impact resistance; durable for daily use

|

Automotive interior parts (door handles), power tool housings, toy vehicles

|

|

Aluminum (A380)

|

310 MPa (45,000 psi)

|

165 MPa (24,000 psi)

|

20 J/m² (14 ft-lb/in²)

|

High tensile strength; resistant to bending/warping

|

Automotive structural parts (transmission housings), industrial pump bodies, LED heat sinks

|

|

Magnesium (AZ91D)

|

230 MPa (33,400 psi)

|

150 MPa (21,800 psi)

|

15 J/m² (11 ft-lb/in²)

|

Ultra-lightweight (1/3 the weight of steel) with decent strength; best for weight-sensitive parts

|

Aerospace components (drone frames), high-end automotive parts (steering columns)

|

- For maximum strength: Aluminum A380 is better than Zamak 5 for load-bearing parts (e.g., holding engine components).

- For strength + impact resistance: Zamak 5 outperforms aluminum (e.g., a Zamak 5 tool housing is less likely to crack if dropped than an aluminum one).

- For strength + light weight: Magnesium AZ91D is the top choice (e.g., a magnesium drone frame is strong enough to handle crashes but keeps the drone light).

Step 3: Process Controls That Boost (or Hurt) Die Casting Strength

1. Porosity (The #1 Enemy of Strength)

- Cause: Fast metal injection traps air in the die; improper venting (no small channels to release air).

- Impact: A porous aluminum A380 part may have tensile strength reduced by 20–30% (from 310 MPa to 220 MPa).

- Fixes:

-

- Use vacuum die casting (removes 90% of air before injection) to cut porosity.

-

- Add die vents (0.1–0.3mm wide) to let air escape as metal fills the cavity.

-

- Post-process with Hot Isostatic Pressing (HIP): Applies high pressure + heat to collapse pores—restoring 95% of the alloy’s full strength.

2. Cooling Speed (Affects Metal Grain Size)

- Cause: Slow cooling (e.g., a thick die or poor water cooling) leads to large grains.

- Impact: Slow-cooled Zamak 5 may have 10–15% lower tensile strength than fast-cooled Zamak 5.

- Fixes:

-

- Use water-cooled dies (channels in the die circulate cold water) to speed up cooling.

-

- Design parts with uniform wall thickness (no thick sections that cool slowly).

3. Heat Treatment (For Aluminum/Magnesium)

- Aluminum A380: Heat-treating to T6 temper (solution heat + aging) increases tensile strength by ~15% (from 310 MPa to 355 MPa) and yield strength by ~30% (from 165 MPa to 215 MPa).

- Magnesium AZ91D: T6 heat treatment raises tensile strength from 230 MPa to 260 MPa.

- Note: Zinc alloys (Zamak) cannot be heat-treated—their strength is fixed by the casting process.

4. Surface Finish (Protects Against Corrosion)

- Anodizing (aluminum): Adds a hard oxide layer that resists corrosion—keeping the part strong for 10+ years in outdoor use.

- Powder Coating (zinc/magnesium): Prevents moisture from reaching the metal, avoiding corrosion-related weakening.

Step 4: Part Design Tips to Maximize Die Casting Strength

- Add Reinforcing Ribs: Thin ribs (1/3 the thickness of the main wall) along stress points (e.g., the base of a bracket) boost strength without adding much weight. For example, a Zamak 5 bracket with ribs can handle 40% more load than one without.

- Avoid Sharp Corners: Sharp corners concentrate stress (like a knife edge)—use rounded edges (radius ≥1mm) to spread stress evenly.

- Uniform Wall Thickness: Thick sections (≥5mm) cool slowly, creating weak grains and porosity. Keep walls 1–3mm thick (for zinc) or 2–4mm thick (for aluminum) and use tapers to avoid thickness changes.

- Minimize Undercuts: Complex undercuts require slides in the die, which can create gaps or thin spots—simplify the design where possible.

Step 5: Die Casting Strength vs. Other Manufacturing Methods

|

Process

|

Typical Strength (Aluminum Example)

|

Strength Tradeoffs

|

Best For

|

|

Die Casting (A380)

|

310 MPa (as-cast); 355 MPa (T6)

|

High strength + fast production; minor porosity possible

|

High-volume, mid-to-high strength parts (10k+ units)

|

|

Sand Casting (A356)

|

230 MPa (as-cast); 310 MPa (T6)

|

Lower strength than die casting; more porous

|

Low-volume, simple parts (100–1k units)

|

|

CNC Machining (6061 Al)

|

310 MPa (T6)

|

Same strength as die cast A380; no porosity

|

Low-volume, precision parts (1–100 units)

|

|

Forging (6061 Al)

|

380 MPa (T6)

|

Strongest option; no porosity

|

High-stress parts (e.g., aircraft landing gear)

|

Step 6: Common Myths About Die Casting Strength

- Myth: “Die casting is weak because it has porosity.”

- Myth: “Zinc die casting is too weak for industrial use.”

- Myth: “Die casting can’t be used for load-bearing parts.”

- Myth: “Thicker walls = stronger parts.”

Step 7: How to Ensure Your Die Cast Part Is Strong Enough

- Pick the right alloy:

-

- Load-bearing parts → Aluminum A380 (T6 heat-treated).

-

- Impact-prone parts → Zinc Zamak 5.

-

- Weight-sensitive parts → Magnesium AZ91D.

- Specify process controls:

-

- Require vacuum die casting (for low porosity).

-

- Ask for water-cooled dies (for fast cooling).

-

- For aluminum: Request T6 heat treatment (if strength is critical).

- Test before production:

-

- Do a tensile test on a prototype (most die casters offer this for (50–)100).

-

- Check for porosity with X-ray inspection (for high-stress parts).