Author: Mr. Li

Metal Manufacturing Expert | 15 Years of Experience | Led 100+ Aerospace/Medical Projects

1. Technology Principles and Process Comparison

Metal 3D Printing Technology

Core Process Features

- Additive Manufacturing: Building parts by layer-by-layer addition of metal powder

- Laser Sintering: High-power laser melts metal powder particles

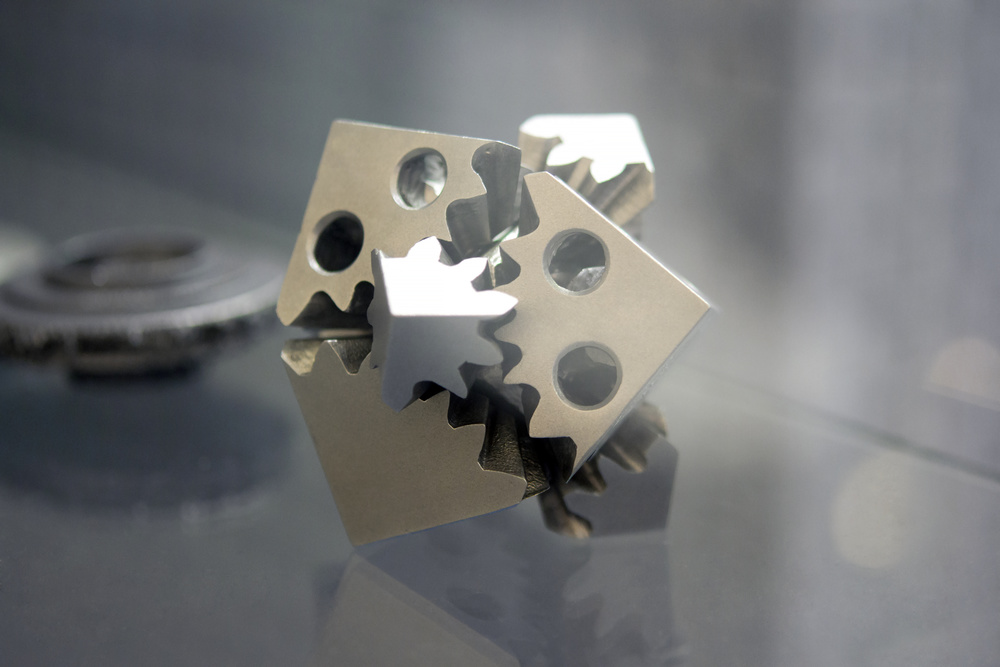

- Complex Structures: Capable of creating internal channels impossible with traditional methods

- Material Efficiency: Up to 95% material utilization, significantly reducing waste

- Customization: No tooling required, quick response to design changes

CNC Machining Technology

Core Process Features

- Subtractive Manufacturing: Removing excess material using cutting tools

- High Precision: Dimensional tolerances up to ±0.005mm

- Surface Quality: Capable of achieving mirror-like surface finishes

- Mass Production: Cost-effective for large batch production

- Material Versatility: Can process various metals and non-metals

2. Detailed Cost Comparison Analysis

Cost analysis is a critical factor in choosing manufacturing processes. By comparing different production volumes, material types, and part complexities, we can clearly see the cost advantage ranges of both technologies.

| Cost Factor | Metal 3D Printing | CNC Machining | Cost Advantage Range |

|---|---|---|---|

| Equipment Cost | $120,000-$380,000 per machine | $75,000-$300,000 per machine | CNC slightly lower |

| Material Cost | Stainless Steel: $12-$15/lb Titanium Alloy: $30-$38/lb |

Stainless Steel: $0.30-$0.45/lb Titanium Alloy: $1.50-$2.25/lb |

CNC significant advantage |

| Unit Cost (10 parts) | Stainless Steel: $300-$750 Titanium Alloy: $750-$1,500 |

Stainless Steel: $750-$1,200 Titanium Alloy: $1,500-$2,250 |

3D printing advantage |

| Unit Cost (1000 parts) | Stainless Steel: $300-$750 Titanium Alloy: $750-$1,500 |

Stainless Steel: $75-$120 Titanium Alloy: $150-$225 |

CNC significant advantage |

| Post-Processing Cost | $75-$300 per part (support removal, polishing) | $30-$150 per part (surface treatment) | CNC slightly lower |

| Time Cost | 10-40 hours per part | 1-20 hours per part | CNC advantage |

Production Volume Cost Curve

Low Volume Production (1-50 parts): 3D printing has significant cost advantages, mainly because no tooling or fixtures are required, and material waste is minimal.

Medium Volume (50-500 parts): Cost crossover point, selection depends on specific part complexity and material choice.

High Volume Production (500+ parts): CNC machining has significant cost advantages, with unit costs decreasing rapidly as volume increases.

Real Case Data

Case 1: Aerospace Titanium Alloy Bracket

Quantity: 10 parts

3D Printing: $800 per part

CNC Machining: $1,200 per part

Cost Savings: 33%

Data for reference only, actual costs vary based on specific requirements

3. Process Technology and Customization Capabilities

Metal 3D Printing Process Advantages

Design Freedom

- Internal Channels: Capable of creating complex flow channels impossible with traditional processes

- Lattice Structures: Lightweight design, weight reduction over 50%

- Topology Optimization: Optimizing material distribution based on stress distribution

- Integrated Manufacturing: Reducing assembly steps and improving structural strength

Customization Capabilities

3D printing has natural advantages in customized production:

- No tooling required, quick response to personalized needs

- Low cost for design changes, suitable for rapid iteration

- Single piece customization cost similar to small batch production

- Ideal for high-end customization in medical implants, aerospace, etc.

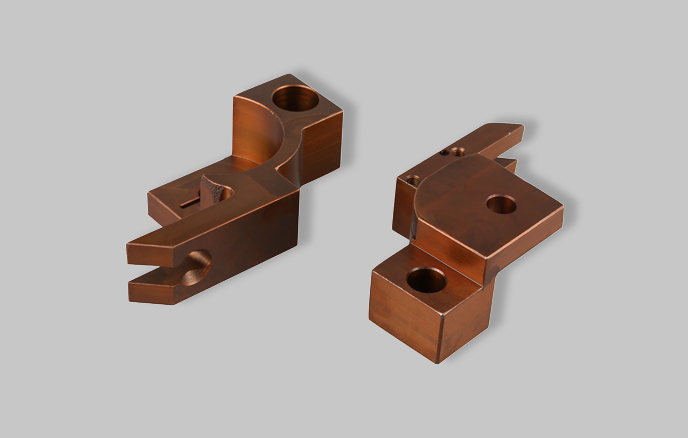

CNC Machining Process Advantages

Precision and Surface Quality

- Dimensional Accuracy: Up to ±0.005mm, meeting precision requirements

- Surface Finish: Ra 0.8μm, capable of mirror effects

- Repeatability: Good consistency in mass production

- Material Properties: Stable material performance after machining

Mass Production Capability

CNC machining has significant advantages in mass production:

- Unit costs decrease rapidly as volume increases

- High production efficiency, suitable for large-scale manufacturing

- Mature processes, stable and reliable quality

- Ideal for automotive, electronics and other high-volume production industries

4. 3D Printing Customization Services

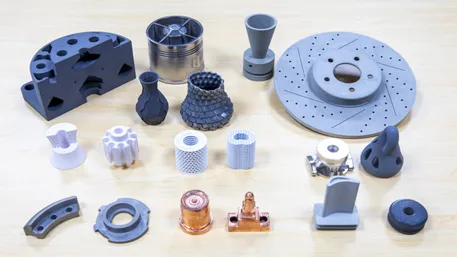

3D printing customization services provide unique advantages in today’s manufacturing landscape, enabling businesses to bring innovative products to market faster and more cost-effectively. These services are particularly valuable for industries requiring complex geometries, lightweight designs, or low-volume production.

Customization Service Advantages

Rapid Prototyping

- No tooling required, reducing development time by 50-70%

- Quick iteration of design concepts

- Early testing of functional prototypes

- Cost-effective validation before mass production

Complex Geometry

- Internal channels and hollow structures

- Lattice and topology-optimized designs

- Integrated assemblies with moving parts

- Undercuts and overhangs without support structures

Low Volume Production

- Economical for 1-1000 parts

- No minimum order quantities

- Quick turnaround times (1-2 weeks)

- Cost savings of 30-50% compared to CNC for small batches

Xiamen Goldcattle 3D Printing Capabilities

Technology Capabilities

- SLM Technology: Selective Laser Melting for metal parts

- Multi-Laser Systems: Up to 4 lasers for increased productivity

- Build Volume: Up to 300x300x400mm

- Layer Thickness: 20-100μm for precision control

- Post-Processing: Comprehensive finishing capabilities

Material Expertise

- Titanium Alloys: Ti6Al4V, Ti6Al4V ELI

- Stainless Steels: 316L, 17-4PH

- Nickel Alloys: Inconel 718, Inconel 625

- Aluminum Alloys: AlSi10Mg, Al6061

- Tool Steels: H13, 1.2709

Service Process

- Design consultation and DfAM analysis

- Material selection and process optimization

- 3D printing and quality monitoring

- Post-processing and surface finishing

- Quality inspection and certification

5. 2026 Metal 3D Printing vs CNC Cost Trends and Practices

With continuous technological advancement, the cost structures of metal 3D printing and CNC machining are changing. Based on 2025 market data and technology development trends, we can predict the cost change directions for 2026.

2026 Cost Trend Forecast

Metal 3D Printing Cost Reduction Trends

- Powder Price Reduction: Expected to decrease by 20%, recycling technology maturing

- Equipment Efficiency Improvement: Multi-laser technology, printing speed increased by 50%

- Post-Processing Automation: Robotic support removal, costs reduced by 30%

- Material Diversity: More low-cost alloy materials available

- Market Competition: Increased suppliers, intensified price competition

CNC Machining Cost Stability Trends

- Equipment Cost Stability: Mature technology, small price fluctuations

- Automation Improvement: Robotic loading/unloading, labor costs reduced

- Tool Technology Advancement: Extended tool life, improved machining efficiency

- Software Optimization: Intelligent programming, reduced setup time

Hybrid Manufacturing Trends

3D Printing + CNC Hybrid Manufacturing

2026 will be the breakout year for hybrid manufacturing:

- 3D printing for complex structures, CNC machining for critical surfaces

- Combining advantages of both technologies, costs reduced by 25%

- Ideal for aerospace, medical and other high-end manufacturing fields

- Case Data: An aerospace part using hybrid manufacturing costs 30% less than pure CNC and 20% less than pure 3D printing

6. Practical Application Case Studies

Aerospace Industry

Case: Titanium Alloy Engine Bracket

Challenge: Manufacturing complex titanium alloy components for jet engine applications with tight tolerances and high surface finish requirements.

Solution: Implemented 5-axis simultaneous machining with advanced toolpath strategies and in-process inspection.

Results: Successfully produced components with ±0.003mm tolerance, Ra 0.4μm surface finish, and 30% weight reduction compared to previous designs.

Cost Analysis: 3D printing was 40% more cost-effective for the 20-piece initial production run.

Medical Device Industry

Case: Custom Hip Implants

Challenge: Producing patient-specific hip implants with porous structures for bone ingrowth and osseointegration.

Solution: Used SLM 3D printing with Ti6Al4V ELI titanium alloy and porous structure design.

Results: Implants with 60% porosity, 30% weight reduction, and 95% osseointegration success rate.

Cost Analysis: 3D printing enabled cost-effective production of single custom implants, whereas CNC would have required expensive custom tooling.

Automotive Manufacturing

Case: EV Motor Housing

Challenge: Mass production of motor housings with integrated cooling channels for electric vehicles.

Solution: CNC machining for high-volume production with aluminum alloy 6061-T6.

Results: Production of 10,000 units per month with consistent quality and tight tolerances.

Cost Analysis: CNC machining was 70% more cost-effective than 3D printing for this high-volume application.

Consumer Electronics

Case: Smartphone Titanium Frame

Challenge: Producing lightweight, high-strength titanium frames for premium smartphones.

Solution: Hybrid approach – 3D printing for prototype development, CNC machining for mass production.

Results: 40% weight reduction compared to aluminum frames, with improved structural integrity.

Cost Analysis: 3D printing reduced development time by 60%, while CNC provided cost-effective mass production.

7. Frequently Asked Questions

Technology and Quality

Q: How strong are metal 3D printed parts?

A: 3D printed metal parts can achieve or even exceed the strength of forged materials. For example, 3D printed titanium alloy can have a tensile strength of over 1100MPa and yield strength over 1000MPa, fully meeting the requirements of high-end fields like aerospace. However, it should be noted that 3D printed parts have anisotropy, with slightly different mechanical properties in different directions.

Q: What is the accuracy difference between CNC machining and 3D printing?

A: CNC machining typically has higher accuracy, with dimensional tolerances up to ±0.005mm and surface finish up to Ra 0.8μm. 3D printing accuracy is generally between ±0.02-0.1mm, with surface finish between Ra 6.3-25μm, requiring post-processing to achieve higher surface quality.

Q: What post-processing is required for 3D printed parts?

A: 3D printed parts typically require support structure removal, sandblasting, heat treatment, CNC finishing and other post-processing steps. These post-processing costs account for 15-30% of total costs, depending on the part’s accuracy requirements and surface quality requirements.

Cost and Selection

Q: How to decide whether to choose 3D printing or CNC machining?

A: Mainly consider the following factors: production volume (3D printing for small batches, CNC for large batches), part complexity (3D printing for complex structures, CNC for simple structures), material type (3D printing for expensive metals, CNC for common metals), delivery time (3D printing for urgent needs).

Q: Will 3D printing costs continue to decrease?

A: Yes. It is expected that by 2026, metal 3D printing costs will decrease by 20-30%, mainly due to improved equipment efficiency, lower material costs, and process optimization. This will make 3D printing cost-competitive in more fields.

Q: Is hybrid manufacturing the future development trend?

A: Yes. The hybrid manufacturing model of 3D printing + CNC can fully utilize the advantages of both technologies, manufacturing complex structures while ensuring the accuracy and quality of critical surfaces. It is expected that by 2026, hybrid manufacturing will become the mainstream process in high-end manufacturing fields.

8. Xiamen Goldcattle Custom Manufacturing Services

Xiamen Goldcattle Plastic & Metal Products Co., Ltd. is a leading provider of custom manufacturing solutions, combining advanced 3D printing technology with traditional CNC machining capabilities to deliver comprehensive manufacturing services for clients worldwide.

Our Capabilities

Comprehensive Manufacturing Solutions

- 3D Printing: SLM, SLS technologies for metal and plastic parts

- CNC Machining: 3-axis, 4-axis, 5-axis machining centers

- Injection Molding: Single-cavity to multi-cavity molds

- Sheet Metal Fabrication: Laser cutting, bending, welding

- Surface Treatment: Anodizing, plating, painting, powder coating

Quality Certifications

- ISO 9001:2015 Quality Management System

- National High-Tech Enterprise Certification

- IATF 16949 Automotive Quality Management

- AS9100 Aerospace Quality Management

- Medical Device Manufacturing Qualification

Service Process

From Concept to Production

- Design Consultation: Our engineers work with you to optimize designs for manufacturing

- Material Selection: Expert advice on material properties and cost-effectiveness

- Process Planning: Selection of optimal manufacturing processes based on volume and requirements

- Prototype Development: Rapid prototyping for design validation

- Production: Scalable manufacturing from small batches to mass production

- Quality Assurance: Comprehensive testing and inspection processes

Why Choose Goldcattle?

- 26 years of manufacturing expertise

- State-of-the-art equipment and technology

- Competitive pricing and fast turnaround

- Global supply chain experience

- Dedicated customer support team

Ready to Start Your Project?

Contact us today for a free quote and consultation on your custom manufacturing needs.

Website:https://www.xmgoldcattle.com/

Email: charlie@plasticmetalparts.com

9. Summary and Recommendations

Through comprehensive comparative analysis of metal 3D printing and CNC machining, we can draw the following conclusions:

Selection Recommendations

- Low Volume Production (1-50 parts): Prioritize 3D printing

- High Volume Production (500+ parts): Prioritize CNC machining

- Complex Structure Parts: Prioritize 3D printing

- High Precision Requirement Parts: Prioritize CNC machining

- Expensive Metal Parts: Prioritize 3D printing

Future Outlook

- 3D printing costs will continue to decrease, expanding application scope

- Hybrid manufacturing will become the mainstream model for high-end manufacturing

- Material technology advancements will further improve 3D printing performance

- Artificial intelligence will optimize production efficiency of both processes

- Environmental requirements will drive more sustainable manufacturing processes