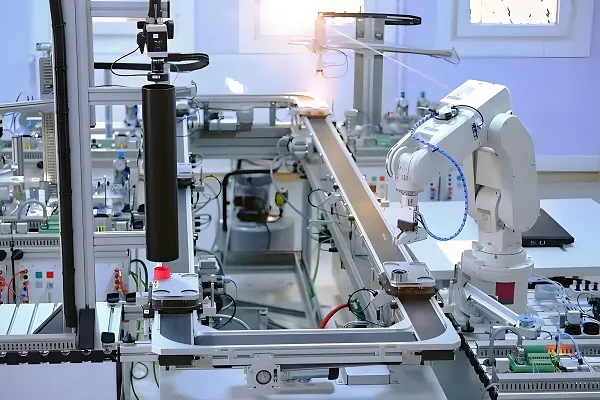

In the realm of international manufacturing and trade, large part machining services play a crucial role in meeting the demands of diverse industries. With advanced technology and expertise, these services offer precision engineering solutions for the production of large-scale components.

Large part machining involves the use of specialized equipment and techniques to shape and finish components that are significantly larger than standard-sized parts. This requires a high level of skill and knowledge to ensure accuracy, quality, and durability.

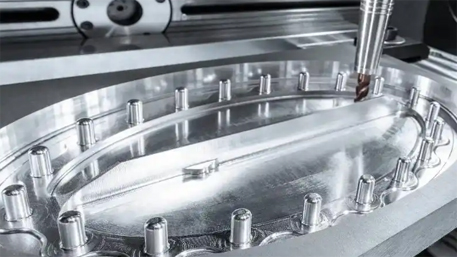

One of the key advantages of large part machining services is the ability to handle complex geometries and tight tolerances. With state-of-the-art computer numerical control (CNC) machines, operators can precisely control the cutting tools to create intricate shapes and dimensions. This is essential for applications where even the slightest deviation can have a significant impact on performance.

For example, in the aerospace industry, large part machining is used to produce components such as turbine blades, engine casings, and structural frames. These parts must meet extremely strict tolerances to ensure proper fit and function in high-performance aircraft. By utilizing advanced machining techniques and quality control measures, large part machining services can deliver parts that meet or exceed the demanding specifications of the aerospace industry.

In the automotive sector, large part machining is employed to manufacture components such as engine blocks, transmission housings, and chassis parts. These parts require precision machining to ensure proper alignment and smooth operation of the vehicle. With the ability to handle large volumes and complex geometries, large part machining services can meet the production demands of the automotive industry while maintaining high quality standards.

To illustrate the capabilities of large part machining services, let’s consider a case study. A leading manufacturer in the oil and gas industry required a large-scale valve body with complex internal passages and tight tolerances. The part measured over 10 feet in length and weighed several tons. By leveraging their expertise in large part machining, a specialized machining service provider was able to produce the valve body with an accuracy of within 0.001 inches. This level of precision ensured proper flow control and reliability in the oil and gas extraction process.

In addition to precision machining, large part machining services often offer value-added services such as welding, heat treatment, and surface finishing. These services can enhance the durability and performance of the machined parts, making them suitable for harsh operating environments.

For instance, in the construction industry, large part machining is used to produce components for heavy machinery and equipment. These parts may require welding to join multiple sections together and heat treatment to improve their strength and hardness. Surface finishing processes such as painting or plating can also be applied to protect the parts from corrosion and wear.

Overall, large part machining services are essential for industries that require precision-engineered components on a large scale. With advanced technology, expertise, and a commitment to quality, these services can deliver solutions that meet the demanding requirements of global markets. Whether it’s for aerospace, automotive, oil and gas, or other industries, large part machining services play a vital role in driving innovation and growth.