As of November 2025, CNC machining continues to power precision manufacturing worldwide, with the global market valued at around $101 billion and poised for steady growth through advanced automation and material innovations. This subtractive process—removing material from a workpiece using computer-controlled tools—demands a blend of technical prowess, practical experience, and forward-looking knowledge. From aerospace turbine components to automotive prototypes, CNC’s versatility shines in achieving tolerances down to ±0.001 inches. At XM GoldCattle, our 20+ years in metal CNC services have refined these elements into reliable workflows. This guide delves into essential techniques, hands-on tips, and key industry insights to elevate your machining outcomes.

Core CNC Machining Techniques: Building a Strong Foundation

Effective CNC starts with mastering the fundamentals: programming, tooling, and process control. G-code, the language of CNC, dictates every movement, from linear feeds (X, Y, Z axes) to rotational cuts (A, B, C axes). Here’s a breakdown of pivotal techniques:

1. Multi-Axis Machining for Complex Geometries

- 3-Axis vs. 5-Axis: 3-axis excels in flat or prismatic parts, using basic X-Y-Z motion for milling slots or drilling holes. Transition to 5-axis for undercuts and contoured surfaces, like impeller blades, where simultaneous axis control reduces setups by 40% and minimizes errors from repositioning.

- Technique Tip: Always simulate paths in CAM software (e.g., Mastercam) to detect collisions— a step that can prevent 80% of programming flaws.

2. Material Selection and Tooling Strategies

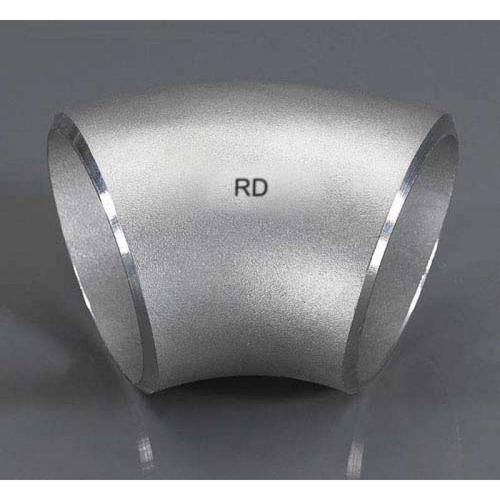

Common materials include aluminum (6061 for lightweight aerospace parts), stainless steel (316 for corrosion-resistant automotive fittings), and titanium (for high-strength medical implants). Pair them with carbide end mills for high-speed operations or diamond-coated tools for composites.

- Workflow Integration: Begin with roughing passes at higher feeds (e.g., 200 IPM on aluminum) to remove bulk material, followed by finishing at lower speeds for Ra 16-32 surface finishes.

For quick reference, compare tooling impacts:

| Material | Recommended Tool | Feed Rate (IPM) | Depth of Cut (in) |

|---|---|---|---|

| Aluminum | Carbide End Mill | 150-300 | 0.050-0.200 |

| Stainless Steel | Cobalt High-Speed Steel | 50-100 | 0.020-0.100 |

| Titanium | TiAlN-Coated Carbide | 30-60 | 0.010-0.050 |

These choices directly influence cycle times and part integrity, drawing from decades of industry refinement.

Practical Tips and Experiences: Lessons from the Shop Floor

CNC success hinges on experience—avoiding pitfalls while honing efficiency. Seasoned machinists emphasize safety and adaptability as non-negotiables.

Essential Safety and Error-Avoidance Tips

- Never Grab Chips Bare-Handed: Hot or sharp debris causes most injuries; use brushes or vacuums instead. Always wear gloves rated for your materials.

- Admit and Learn from Mistakes: A misprogrammed feed can scrap a part—pause, consult logs, and iterate. Listening to veterans on the floor often uncovers shortcuts, like adjusting coolant flow to curb thermal distortion in aluminum.

- Tool Life Management: Monitor wear via vibration sensors; replace at 70% life to avoid breakage, extending overall uptime by 25%.

Optimization Techniques for Efficiency

- Feed and Speed Calculators: Use apps or formulas (SFM = RPM × Tool Diameter × 0.262) to baseline settings, then tweak based on spindle load—aim for 70-80% utilization to balance speed and finish.

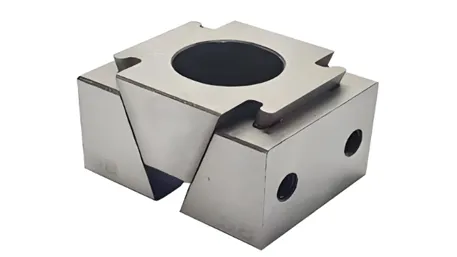

- Fixture Design: Secure workpieces with soft jaws or vacuum tables to minimize vibration; this technique cuts deflection in long parts, improving tolerances by 15%.

From our projects at XM Gold Cattle, one tip stands out: For high-volume runs, batch similar geometries to streamline tool changes, reducing setup time from hours to minutes—a hard-won lesson from automotive gear productions.

Industry Knowledge: 2025 Insights and Emerging Practices

The CNC landscape in 2025 is shaped by automation, skills development, and sustainability, addressing labor shortages and environmental mandates.

1. Automation and AI Integration

Robotic arms for loading/unloading boost throughput by 30%, while AI algorithms predict tool paths and detect anomalies in real-time. Industry knowledge: Start with plug-and-play cobots for SMEs; they integrate via standard APIs, easing the transition from manual to semi-autonomous lines.

2. Addressing the Skills Gap

With machinist shortages projected at 20% through 2030, upskilling via VR simulations and apprenticeships is key. Tip: Pair new hires with mentors for G-code debugging—retention improves 40% with structured programs.

3. Sustainable Machining Practices

Opt for biodegradable coolants and recycled alloys to meet EU REACH standards; dry machining with compressed air cuts fluid use by 50% without sacrificing quality. Emerging knowledge: Hybrid CNC-3D printing workflows minimize waste, ideal for on-demand aerospace prototyping.

These practices reflect broader shifts, where 70% of manufacturers prioritize multi-axis versatility for competitive edges.

Real-World Application: Precision Gears in Automotive CNC

In a recent automotive project, we machined 1,000 helical stainless steel gears using 5-axis techniques: AI-optimized paths ensured ±0.003 mm tolerances, while sustainable tooling reduced energy by 18%. The result? Zero rework and accelerated timelines—proof that blending techniques with experience yields superior outcomes.

CNC machining rewards precision and curiosity. What’s one technique you’ve refined in your workflow, or a challenge you’re tackling? Share in the comments—our experts at XM Gold Cattle respond with tailored insights. Dive deeper at https://www.xmgoldcattle.com/services/cnc-machining for technique templates and case studies.