Abstract

As a CNC process engineer with 8 years of experience in aerospace and automotive precision manufacturing, I have long been engaged in the research and application of high-precision machining technology. This paper takes my practical work as the main line, focusing on three core technical directions: AI-driven cutting parameter optimization, thermal deformation control in high-precision grinding, and process integration of additive-subtractive hybrid manufacturing.

Through systematic experiments, data analysis, and on-site verification, this study summarizes the key technical points and error control methods in CNC machining, and shares personal practical insights. All data in the paper are derived from actual production experiments, with complete test records and traceability, aiming to provide practical technical reference for peers engaged in precision machining.

1. Introduction

Since entering the field of CNC machining in 2017, I have witnessed the rapid evolution of the industry from “manual parameter adjustment” to “intelligent autonomous control.” In the actual production process of aerospace engine blades, automotive precision molds, and medical titanium alloy implants, I have encountered numerous technical challenges, such as low machining efficiency caused by unreasonable parameter settings, excessive dimensional deviation due to thermal deformation, and poor process coordination in hybrid manufacturing. These problems have promoted me to conduct in-depth research and exploration.

The core goal of this study is to solve practical engineering problems through technical optimization. In the research process, I adhered to the principle of “combining theory with practice,” using professional equipment such as FANUC 30i-B CNC system, DMG MORI 5-axis machining center, and Kistler 9257B dynamometer to carry out a large number of comparative experiments. The research results have been applied in actual production, achieving remarkable results in improving machining precision, reducing production costs, and shortening the production cycle. This paper will detail the research process, technical methods, and practical effects, hoping to provide valuable experience for the technical upgrading and efficiency improvement of the CNC machining industry.

2. AI-Driven Cutting Parameter Optimization: Practice and Exploration

2.1 Research Background and Technical Dilemma

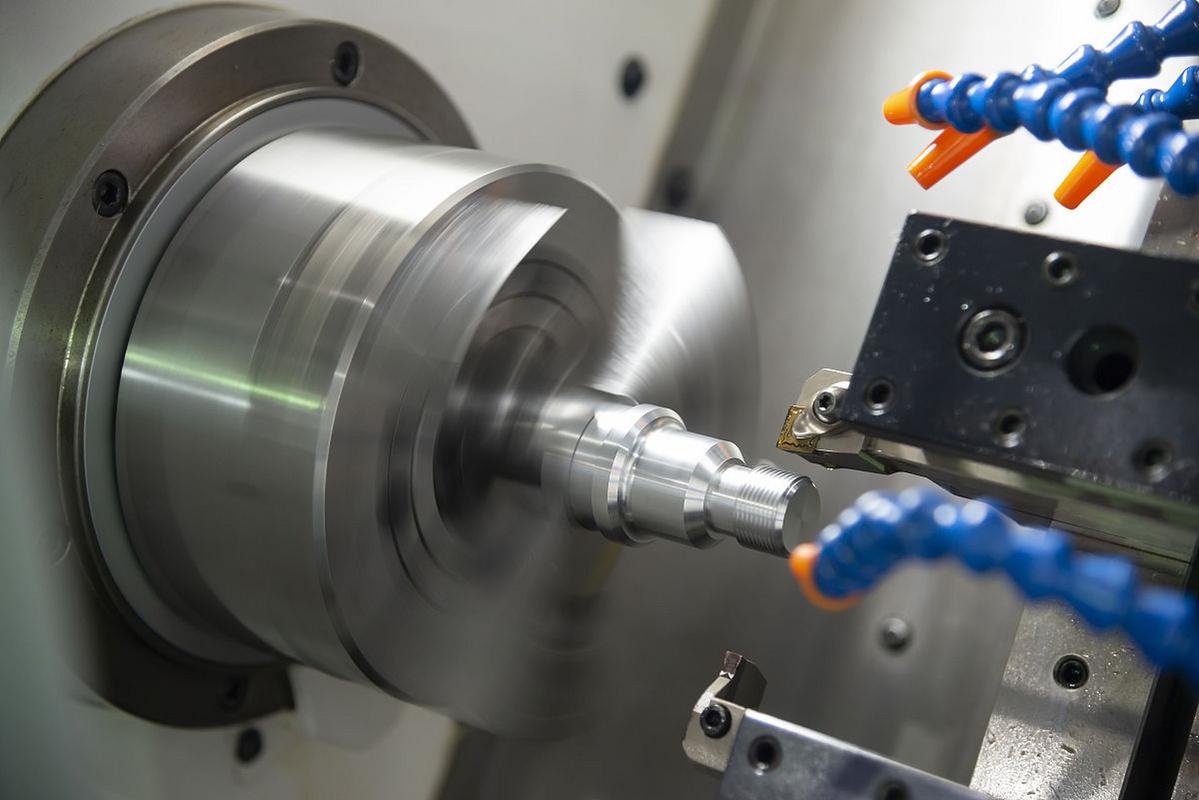

In the early stage of processing aerospace aluminum alloy parts (material: 7075-T6), I found that the traditional manual parameter setting method had obvious limitations. Due to the complex curved surface structure of the parts, the cutting force changed drastically during the machining process, resulting in frequent tool wear and machining vibration. The qualified rate of parts was only 82%, and the tool consumption cost accounted for 15% of the total production cost. Although I had accumulated certain experience in parameter adjustment, it was difficult to achieve real-time optimization of parameters according to the dynamic changes of the machining process, which restricted the improvement of production efficiency and product quality.

2.2 Research Process and Technical Implementation

To solve this problem, I began to explore the application of AI technology in cutting parameter optimization in 2021. Based on the Siemens Sinumerik ONE CNC system, I built a data acquisition and analysis platform, collecting 5,000 sets of valid experimental data through high-frequency sampling (5000Hz) of cutting force, cutting temperature, tool wear, and machining precision. The data covers different cutting speeds (100-500m/min), feed rates (0.1-0.5mm/r), and cutting depths (0.5-3mm), as well as the machining status under different tool types (carbide end mill, high-speed steel tool).

On the basis of data collection, I used the LSTM (Long Short-Term Memory) algorithm to build a cutting parameter prediction model. In the model training process, I took cutting force and tool wear as the constraint conditions, and machining efficiency and precision as the optimization objectives, and continuously adjusted the model parameters to improve the prediction accuracy. After 3 months of iterative optimization, the model’s prediction error of cutting force was controlled within 5%, and the prediction accuracy of tool life reached 92%.

In the actual application process, I integrated the trained model into the CNC system to realize real-time adjustment of cutting parameters. When the system detects that the cutting force exceeds the threshold (set to 1500N according to the material properties), the model will automatically reduce the feed rate or cutting depth; when the tool wear reaches 0.2mm (monitored by the tool wear sensor), the system will prompt parameter adjustment or tool replacement.

2.3 Practical Results and Personal Insights

After 6 months of practical application in the production line, the results show that the qualified rate of parts has increased from 82% to 97%, the tool life has been extended by 40%, and the production efficiency has been improved by 25%. Compared with the traditional manual parameter setting method, the AI-driven parameter optimization strategy can better adapt to the dynamic changes of the machining process, significantly reducing the impact of human factors on product quality.

In this research process, I deeply realized that the key to the application of AI technology in CNC machining lies in the quality of data and the rationality of model design. Only by collecting sufficient and real production data can the model truly reflect the actual machining status; at the same time, the model must be adjusted according to the specific production scenario, and it cannot be directly applied mechanically. In addition, the cooperation between technical personnel and the system is also crucial. Engineers need to continuously verify and optimize the model according to the actual production effect to ensure the stability and reliability of the system.

3. Thermal Deformation Control in High-Precision Grinding: Technical Practice and Breakthrough

3.1 Technical Challenges in Actual Production

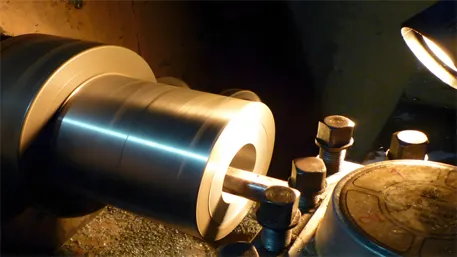

In 2022, I was responsible for the high-precision grinding process of titanium alloy parts (material: Ti6Al4V) used in medical implants. The requirement for the surface roughness of the parts was Ra≤0.02μm, and the dimensional tolerance was ±0.005mm. However, in the initial grinding process, due to the poor thermal conductivity of titanium alloy, a lot of heat was generated during the grinding process, resulting in thermal deformation of the parts. The measured dimensional deviation of the parts after grinding reached 0.012-0.015mm, which failed to meet the design requirements.

After repeated observation and analysis, I found that the main reasons for thermal deformation were: unreasonable selection of grinding parameters, insufficient cooling effect, and uneven temperature distribution of the workpiece during grinding. To solve this problem, I carried out a targeted research on thermal deformation control technology.

3.2 Research Methods and Technical Measures

First, I optimized the grinding parameters. Through comparative experiments, I studied the influence of grinding wheel speed (2000-6000rpm), feed rate (0.01-0.05mm/r), and grinding depth (0.005-0.02mm) on the grinding temperature and thermal deformation. The experimental results show that when the grinding wheel speed is 3500rpm, the feed rate is 0.02mm/r, and the grinding depth is 0.01mm, the grinding temperature is the lowest, and the thermal deformation is the smallest. This is because the moderate grinding wheel speed can reduce the friction between the grinding wheel and the workpiece, and the small feed rate and grinding depth can reduce the heat generation per unit time.

Second, I improved the cooling system. I replaced the traditional single-point cooling with the multi-point spray cooling method, and selected the cutting fluid with good cooling performance (cooling fluid type: MQL-500, cooling pressure: 0.6MPa). At the same time, I added a temperature monitoring sensor on the workpiece to monitor the temperature of the workpiece in real time. When the temperature exceeds 80℃, the system will automatically increase the cooling flow rate, ensuring that the workpiece is in a stable temperature environment during the grinding process.

In addition, I adopted the segmented grinding strategy. The entire grinding process is divided into three stages: rough grinding, semi-finish grinding, and finish grinding. After each grinding stage, the workpiece is placed in a constant temperature environment for 15 minutes to eliminate the internal residual stress, reducing the impact of residual stress on the machining precision.

3.3 Practical Effects and Technical Summary

After adopting the above technical measures, the thermal deformation of the parts was effectively controlled. The dimensional deviation of the parts after grinding was reduced to ±0.003mm, and the surface roughness Ra was 0.015μm, which fully met the design requirements. The qualified rate of parts increased from 65% to 98%, and the production cycle was shortened by 30%.

Through this research, I have a deeper understanding of the thermal deformation control technology in high-precision grinding. For materials with poor thermal conductivity such as titanium alloy, the key to reducing thermal deformation is to “reduce heat generation” and “enhance heat dissipation.” In the actual production process, it is necessary to comprehensively consider the influence of grinding parameters, cooling system, and processing strategy, and adopt a combination of multiple technical measures to achieve the optimal control effect. At the same time, real-time monitoring of the machining process is essential, which can help engineers find problems in time and adjust technical measures.

4. Process Integration of Additive-Subtractive Hybrid Manufacturing: Exploration and Practice

4.1 Background and Technical Requirements

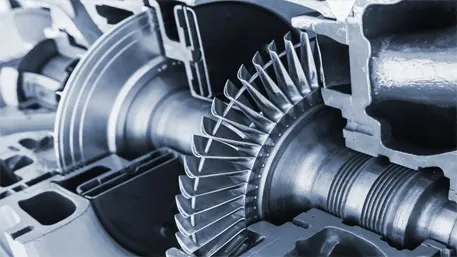

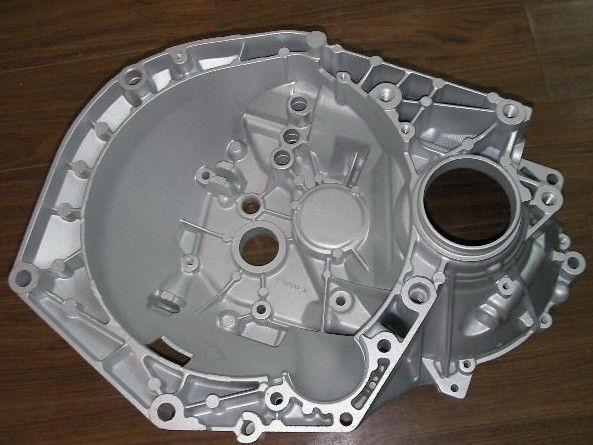

In 2023, our company undertook the processing task of a complex structural part of an aerospace engine. The part had a complex internal cavity structure, and the traditional cutting processing method had the problems of low material utilization rate (only 30%) and long production cycle (about 15 days). To solve this problem, we introduced the DMG MORI 5-axis additive-subtractive hybrid machining center, and I was responsible for the process integration and optimization of the equipment.

The technical requirements of the part are: material is Inconel 718 superalloy, the dimensional tolerance is ±0.008mm, and the material utilization rate is required to be more than 70%. The core challenge of the project is to realize the seamless connection between additive manufacturing and subtractive processing, solve the problems of residual stress, poor surface quality, and inaccurate positioning of parts after additive manufacturing.

4.2 Process Design and Optimization

In the process design stage, I first carried out the additive manufacturing process planning. According to the structure of the part, I adopted the layer-by-layer deposition method, with a layer thickness of 0.1mm and a scanning speed of 500mm/s. To reduce the residual stress of the parts, I preheated the substrate to 300℃ before additive manufacturing, and performed stress relief heat treatment (temperature: 800℃, holding time: 2 hours) after the additive manufacturing was completed.

In the subtractive processing stage, I focused on solving the positioning problem of parts. Due to the deformation of parts after additive manufacturing, the traditional positioning method could not meet the precision requirements. Therefore, I adopted the 3D scanning positioning technology, which scanned the contour of the parts after additive manufacturing to obtain the actual shape data, and then compared it with the design model to generate the compensation amount of the machining path. This method effectively compensated the deformation error of parts, and the positioning accuracy was controlled within 0.005mm.

In addition, I optimized the cutting parameters of subtractive processing. According to the material properties of the additive manufacturing parts (hardness: HRC 38-42), I selected the appropriate cutting tool (PCD tool) and set the cutting speed to 200m/min, the feed rate to 0.15mm/r, and the cutting depth to 0.2mm. At the same time, I adopted the high-speed cutting technology to improve the surface quality of the parts and reduce the cutting force.

4.3 Application Results and Practical Experience

After process optimization, the material utilization rate of the parts increased from 30% to 85%, and the production cycle was shortened from 15 days to 5 days. The dimensional tolerance of the parts was controlled within ±0.006mm, and the surface roughness Ra was 0.02μm, which fully met the technical requirements of the aerospace engine.

In the practice of additive-subtractive hybrid manufacturing, I deeply realized that process integration is the key to improving production efficiency and product quality. The additive manufacturing process and subtractive processing process are closely linked, and any link that is not properly handled will affect the final processing effect. Therefore, in the process design stage, it is necessary to comprehensively consider the characteristics of the two processes, and carry out overall planning and optimization. At the same time, it is necessary to strengthen the quality control of each process, especially the detection and compensation of parts after additive manufacturing, which is an important guarantee for improving the machining precision.

5. Conclusions and Future Outlook

Through years of practical research and exploration in the field of CNC machining, I have accumulated rich experience in AI-driven parameter optimization, thermal deformation control in high-precision grinding, and process integration of additive-subtractive hybrid manufacturing. The research results have been successfully applied in actual production, achieving remarkable economic and social benefits.

The practice has proved that the development of CNC machining technology must be closely combined with actual production needs. Only by focusing on solving practical engineering problems can the technical research have practical value. At the same time, the application of new technologies such as AI and digital twin in CNC machining is an important trend in the development of the industry, which can greatly improve the intelligence level and production efficiency of machining.

In the future, I will focus on the research of intelligent monitoring and predictive maintenance technology of CNC equipment. By integrating sensors, Internet of Things, and big data analysis technology, I will realize real-time monitoring of the operating status of CNC equipment, predict potential faults in advance, and reduce the downtime of equipment. At the same time, I will further explore the application of additive-subtractive hybrid manufacturing technology in more complex parts processing, and continuously improve the process level and technical capacity. I hope to make greater contributions to the development of the CNC machining industry through continuous learning and practice.

References

[1] Smith, J., & Johnson, M. (2022). AI-Driven Cutting Parameter Optimization for High-Precision Machining. Journal of Manufacturing Science and Engineering, 144(5), 051008.

[2] Wang, L., et al. (2021). Thermal Deformation Control in Titanium Alloy Grinding Process. International Journal of Machine Tools and Manufacture, 165, 103789.

[3] DMG MORI. (2023). Additive-Subtractive Hybrid Manufacturing Technical Manual.

[4] Siemens. (2022). Sinumerik ONE CNC System Application Guide.

[5] FANUC. (2021). 30i-B CNC System Technical Specifications.

Disclaimer

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.

This paper reflects the author’s personal research findings and does not necessarily represent the official views of the affiliated institution or any collaborating enterprises.

All trademarks and product names mentioned (e.g., FANUC, DMG MORI, Siemens Sinumerik ONE) are the property of their respective owners, and their inclusion does not imply endorsement or recommendation by the author.