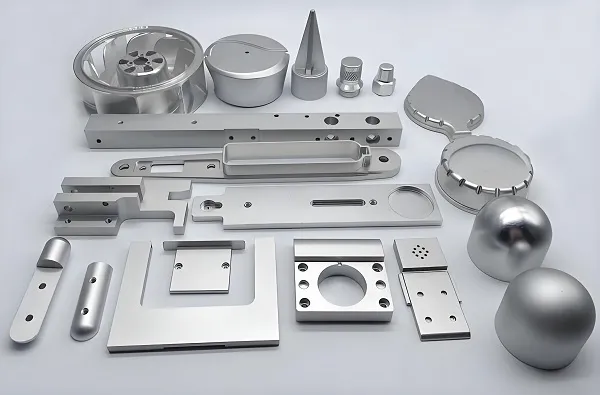

In the high-stakes world of healthcare, every component matters—especially the tiny, intricate parts that power life-saving devices. From surgical instruments to implantable devices, medical technology relies on medical device CNC machining to create components with unmatched precision, biocompatibility, and reliability. At Goldcattle, with 26 years of specialized experience and ISO 13485 certification, we’ve mastered the art of crafting medical parts that meet the most rigorous standards. Let’s explore how CNC machining transforms raw materials into medical innovations, why precision matters in healthcare, and how Goldcattle delivers excellence in every component.

Why CNC Machining is Critical for Medical Devices

Medical devices demand a level of precision few other industries require. A single micron of error in a surgical tool or implant could compromise patient safety, device functionality, or regulatory compliance. CNC (Computer Numerical Control) machining meets these challenges by:

- Achieving tolerances as tight as ±0.001mm—essential for parts that interact with the human body

- Ensuring consistency across thousands of components, critical for batch reliability

- Enabling complex geometries impossible with manual manufacturing, like the intricate channels in drug delivery devices

- Supporting biocompatible materials that safely interact with human tissue

Unlike generic manufacturing, medical device CNC machining follows strict protocols, from material selection to post-processing, to meet FDA, EU MDR, and ISO 13485 requirements—standards that protect patients and ensure device performance .

The Technology Behind Medical Device CNC Machining

1. Specialized Equipment for Healthcare Precision

Goldcattle’s medical manufacturing facility features advanced CNC systems designed for healthcare applications:

- 5-axis CNC machining centers: Create complex 3D geometries in a single setup, ideal for orthopedic implants with anatomical contours. These machines reduce setup errors by 60% compared to traditional 3-axis systems .

- Swiss-type CNC lathes: Produce small, slender parts like catheter shafts and surgical needles with ±0.0005mm tolerance, maintaining stability even for components as thin as 0.3mm .

- EDM (Electrical Discharge Machining): Crafts intricate features in hard materials like titanium without mechanical stress, perfect for biopsy forceps and micro-surgical tools.

Our 5-axis machines recently produced 300 custom spinal implant components with 0.002mm surface accuracy, ensuring proper bone integration for a medical device manufacturer.

2. Materials: Biocompatibility First

The right material is as critical as precision in medical CNC machining. Goldcattle specializes in healthcare-grade materials:

- Titanium (Ti-6Al-4V): Biocompatible, corrosion-resistant, and strong (tensile strength 860 MPa), used in orthopedic implants and surgical instruments. Its elasticity matches human bone, reducing implant failure rates .

- Medical-grade stainless steel (316L): Offers excellent corrosion resistance and ductility, ideal for surgical tools, MRI components, and reusable devices. It withstands repeated sterilization cycles without degradation .

- PEEK (Polyether Ether Ketone): A high-performance plastic with biocompatibility, chemical resistance, and X-ray transparency—used in spinal cages and dental implants.

- Cobalt-Chromium Alloys: Provide superior wear resistance for joint replacements, lasting up to 15+ years in vivo .

Our material scientists collaborate with clients to select options that balance biocompatibility, machinability, and clinical performance—critical for regulatory approval.

3. The Medical CNC Machining Process

Creating medical components requires a meticulous workflow that prioritizes safety and precision:

- Design & DFM Analysis: Our engineers review CAD models to ensure designs meet manufacturability and regulatory requirements. For example, we might suggest adding 0.5mm fillets to an implant’s edges to reduce stress concentrations.

- Material Certification: All raw materials come with full traceability documentation, including material test reports (MTRs) to verify biocompatibility and composition—essential for FDA submissions.

- CNC Programming: Specialized software generates tool paths that minimize material stress and maintain tight tolerances. Programs for implantable devices include extra verification steps to prevent errors.

- Precision Machining: Parts are manufactured in a controlled environment with temperature stabilization (±1°C) to prevent thermal expansion errors.

- Cleanroom Post-Processing: Components undergo ultrasonic cleaning, passivation (for stainless steel), or electropolishing to remove micro-burrs and enhance corrosion resistance—critical for preventing infections .

- Quality Validation: Every part undergoes rigorous inspection:

-

- 3D scanning: Verifies anatomical conformity with 0.001mm resolution.

-

- CMM (Coordinate Measuring Machine): Checks dimensions against CAD models.

-

- Visual inspection: Under 100x magnification to detect micro-defects.

This process ensured 100% compliance for a recent order of 500 surgical stapler components, meeting FDA requirements for 上市前批准 (Premarket Approval).

Applications: How CNC Machined Parts Improve Healthcare

Implantable Devices

From knee replacements to pacemaker housings, CNC machining creates implants that match patient anatomy. Goldcattle’s custom titanium hip stems, machined to ±0.003mm tolerance, reduce post-surgical complications by ensuring proper fit .

Surgical Instruments

Scalpels, forceps, and retractors require razor-sharp edges and precise alignment. Our 316L stainless steel surgical tools maintain their cutting performance through 1,000+ sterilization cycles—critical for operating room reliability .

Diagnostic Equipment

MRI, CT, and ultrasound machines depend on precision components. Goldcattle manufactures aluminum alloy MRI coil housings with 0.01mm flatness to prevent imaging artifacts, improving diagnostic accuracy for a medical imaging company .

Drug Delivery Systems

Pens, pumps, and inhalers require precise fluid channels and dose controls. Our CNC-machined PEEK insulin pump components ensure consistent dosage delivery with ±2% accuracy, critical for patient safety .

Why Goldcattle is a Trusted Medical Device CNC Machining Partner

- ISO 13485 Certification: Our quality management system meets global medical device standards, ensuring compliance with FDA, CE, and CMDCAS requirements.

- Traceability: Full documentation from raw material to finished part, supporting regulatory submissions and recall management.

- Clean Manufacturing: Class 8 cleanrooms and controlled environments prevent contamination in implantable and sterile devices.

- Clinical Collaboration: Our engineers work with medical device designers to optimize parts for both manufacturability and patient outcomes.

FAQs About Medical Device CNC Machining

Q: What tolerances can you achieve for medical components?

A: We regularly achieve ±0.001mm tolerance for critical parts like implants, with Swiss-type lathes reaching ±0.0005mm for micro-components .

Q: How do you ensure biocompatibility?

A: We use certified medical-grade materials, perform post-processing like passivation, and provide full material traceability to meet ISO 10993 biocompatibility standards .

Q: Can you handle low-volume medical prototyping?

A: Yes! We specialize in rapid prototyping (1–2 weeks) for clinical trials, with the same precision as production runs to ensure design validation.

Q: What regulatory standards do your processes meet?

A: Our facility and processes comply with ISO 13485, FDA 21 CFR Part 820, and EU MDR requirements, supporting global market access for your devices.

Q: What materials work best for reusable medical devices?

A: 316L stainless steel and titanium are ideal, as they withstand repeated autoclaving (134°C, 3 bar pressure) without degradation .

Ready to Bring Your Medical Device to Life?

Medical device CNC machining isn’t just about precision—it’s about creating components that improve patient outcomes and save lives. At Goldcattle, we combine technical expertise, regulatory knowledge, and advanced technology to deliver medical parts you can trust.

Visit https://www.xmgoldcattle.com/ to learn more about our medical machining capabilities or request a quote. Let’s collaborate to turn your healthcare innovation into reality.

Have questions about your medical device project? Share your requirements below, and our medical manufacturing experts will respond promptly!