The moment liquid metal is poured into a mold, humanity embarks on a casting history spanning thousands of years. Conversely, when laser beams trace layer by layer on a bed of metal powder, metal 3D printing infuses modern manufacturing with disruptive power through its novel “additive manufacturing” logic. How do these two metal part manufacturing processes, representing “ancient wisdom” and “cutting-edge technology” respectively, compare in terms of advantages and disadvantages? And how should one make the optimal choice based on specific needs? This article

will delve into their core differences from multiple dimensions, including process principles, design adaptability, production scale, delivery cycle, and application scenarios.

Process Principles: Fundamental Differences from “Shaping” to “Growing”

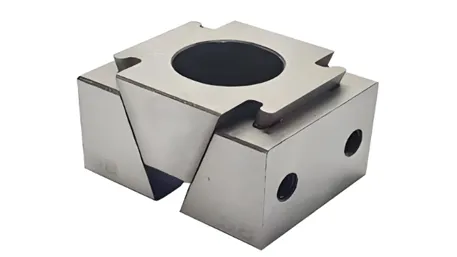

The logic of traditional casting is “form follows mold.” Its core process revolves around the “mold”: first, a mold with corresponding cavities is created according to the final shape of the part. Then, molten liquid metal (or other materials) at high temperature is poured into the mold cavity. After the metal cools and solidifies naturally, the mold is removed to obtain the preliminary casting. Subsequent finishing processes such as grinding and polishing can be carried out as required. This process essentially extends the “subtractive thinking” – by restricting the flow space of the metal through the mold, the desired shape is achieved. However, due to factors such as the cooling rate and fluidity of the metal, the overall process is time-consuming.

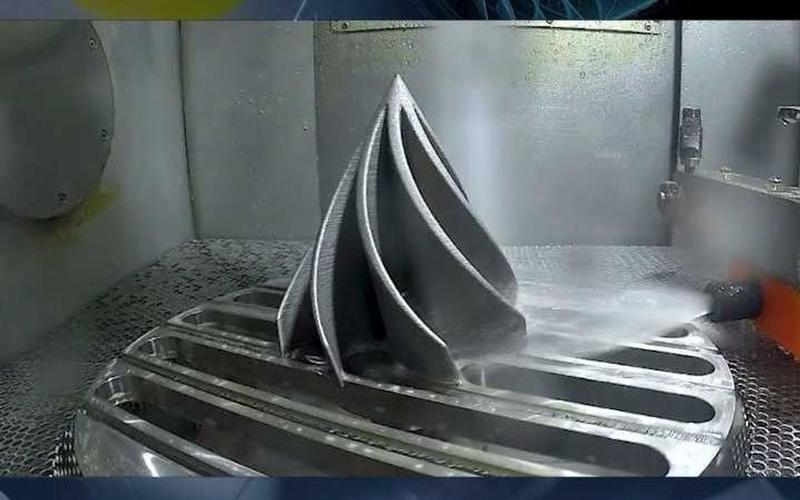

Metal 3D printing (taking the widely used Direct Metal Laser Sintering, DMLS, as an example) completely subverts this logic, adopting an “additive manufacturing” model of “growing layer by layer.” Using metal powder as raw material, a high-power laser beam controlled by a computer sinters and melts the powder layer by layer according to the preset CAD model path. After each layer is printed, the printing platform moves downward by the thickness of one layer, and then new metal powder is evenly spread on the surface for the sintering process of the next layer. Eventually, the part “grows” out of the powder bed, forming directly without the need for a mold, and can achieve a material density close to 100%, with mechanical properties comparable to those of castings.

Design Adaptability: A Tripartite Struggle of Complexity, Precision, and Size

Part design is a crucial factor in determining which process to choose, and the two processes have significant differences in their adaptability to complexity, precision, and size.

In terms of part complexity, casting is more suitable for parts with simple structures and no fine features. If a part only requires a basic shape and does not need extensive subsequent processing, casting can complete production through a single pouring. However, once complex geometric structures are involved (such as internal hollows, tiny holes, irregular curved surfaces), the limitations of casting become apparent – liquid metal has difficulty flowing adequately through small mold channels, 极易 leading to problems such as incomplete filling and material shortages, resulting in part rejection. In contrast, 3D printing has an innate advantage in adapting to complex structures. Whether it’s millimeter-scale fine features or intricate internal channels, they can be precisely achieved through layered printing. However, 3D printed parts require the addition of support structures during the printing process to prevent deformation, and a post-processing step of support removal is needed after printing.

In terms of precision control, both processes have their own advantages and disadvantages and are suitable for different scenarios. Although casting can produce simple parts with small tolerances and good surface finish, when dealing with complex assemblies, parts often need to be divided into multiple modules for separate casting and then joined by brazing or other methods. This process not only increases the number of steps but also may reduce the overall precision due to assembly errors. Additionally, the natural shrinkage of metal during cooling further decreases dimensional accuracy, and factors such as material properties and pouring temperature also affect the final precision. 3D printing, on the other hand, can stably achieve high-precision molding of fine features with its digitally controlled laser beam. More importantly, mainstream 3D printing service providers usually offer “Design for Manufacturing (DFM)” feedback – when submitting a CAD model, the system automatically evaluates the printability of the part, avoiding designs that are printable but unreasonable and ensuring precision from the source.

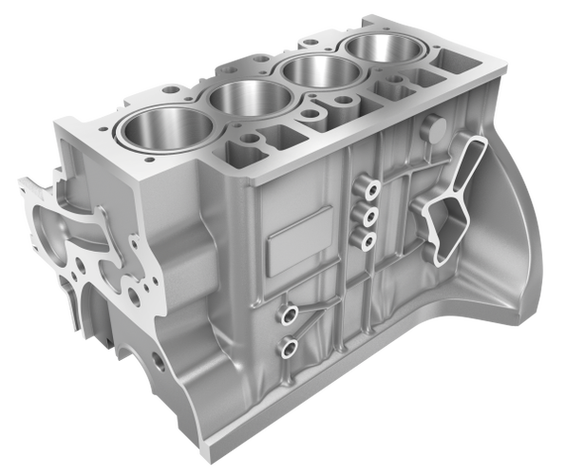

In terms of part size, casting still has a significant advantage. Although some high-end metal 3D printers can produce parts with a maximum size of 31.5 inches × 15.7 inches × 19.7 inches (400mm×800mm×500mm), for larger components (such as several-meter-long bridge parts or ship propellers), casting is a more economical and feasible choice. However, the size limitations of 3D printing are continuously being broken, with new equipment and technologies emerging every year, gradually expanding its application boundaries in large part manufacturing.

It is worth noting that both processes have clear requirements for “uniform wall thickness and fillet design” – parts with these design features can achieve more stable stress distribution, reduce shrinkage deformation, improve dimensional accuracy and mechanical properties, and optimize material utilization and reduce costs during both the cooling and solidification process of casting and the interlayer bonding process of 3D printing.

Production Scale and Cost: The “Cost-Effectiveness Balance” Determined by Quantity

Production quantity is a core variable affecting process costs, and the cost curves of the two processes exhibit distinctly different trends.

The core advantage of metal 3D printing lies in low-volume production. Since there is no need to produce molds, its startup cost is almost zero. Whether it’s a few prototype parts or small batches of dozens or hundreds of end-use parts, production can be quickly initiated. Additionally, 3D printing supports “nested batch printing” – multiple small parts can be placed simultaneously on the same printing platform, significantly shortening the overall production cycle. However, as the production quantity increases, the cost reduction of 3D printing is limited because its cost is mainly determined by material consumption and equipment operation time, and increasing the batch size does not significantly reduce the unit cost.

Traditional casting is the opposite, with its cost advantage emerging in high-volume production. The core cost of casting is concentrated in mold production. A set of high-precision molds often requires high design and manufacturing costs, and there is a waiting time for the casting factory’s production schedule. However, once the mold is completed, the subsequent pouring and forming processes are relatively inexpensive. The more parts produced, the less the mold cost is amortized per unit, resulting in a much lower unit cost compared to 3D printing for large production volumes. Therefore, for production runs of thousands or tens of thousands of parts, casting is the better choice. But for small batches of just dozens or even a few parts, the mold cost and waiting time for casting are not cost-effective.

Comparison Table of Metal 3D Printing vs. Traditional Casting

| Comparison Dimension | Metal 3D Printing (SLM/EBM) | Traditional Casting (Sand Casting/Investment Casting) |

|---|---|---|

| Material Types | Titanium alloys, stainless steel, aluminum alloys, nickel-based alloys, etc. | Cast iron, cast aluminum, bronze, etc. |

| Forming Precision | ±0.1 – 0.2mm | ±0.5 – 2mm |

| Surface Roughness | Ra 10 – 30μm | Ra 25 – 100μm |

| Internal Defects | Almost no shrinkage cavities or porosity | Prone to gas holes and shrinkage porosity |

| Mechanical Properties | Anisotropic, tensile strength increased by 10%-20% | Isotropic, requires heat treatment for strengthening |

| Production Cycle | Single part: 4-24 hours | Mold production: 7-15 days, single part: 4-8 hours |

| Unit Cost | $100-$5000 (decreases with complexity) | $50-$2000 (decreases with batch size) |

| Batch Production Cost | Unit cost fluctuates slightly with quantity increase | Cost drops significantly when batch size > 50 |

| Complex Structure Manufacturing Ability | Supports hollow, lattice, and multi-material composite structures | Complex structures require multiple assembly processes |

| Material Utilization | 70%-95% | 40%-60% |

| Design Freedom | No restrictions on topology optimization structures | Constrained by draft angles and parting surfaces |

Delivery Cycle: The Time Gap between “Days” and “Years”

In modern manufacturing, where “time is efficiency,” the delivery cycle often becomes a crucial decision factor, and the difference between the two processes in this dimension is vast.

The delivery cycle of traditional casting is extremely long, potentially exceeding a year. This is mainly due to two reasons: first, resources at casting factories are in high demand, and the production schedules of high-quality casting factories are usually booked months or even half a year in advance; second, mold production is time-consuming. Even if existing molds are available, they may need to be repaired or remade due to improper storage or wear. Once there are problems with the mold, the entire production process has to start over. Even if everything goes smoothly, the processes of metal melting, pouring, cooling, and mold removal still require a long waiting time.

Metal 3D printing completely breaks through this limitation, with its delivery cycle measured in “days.” For medium-sized parts with non-extremely complex structures, it usually only takes a few days from CAD model confirmation to printing completion. Even for large parts, although the printing time will increase accordingly, the overall cycle is still much shorter than that of casting. More importantly, the design iteration cost of 3D printing is extremely low – if part design modifications are needed, only the CAD model needs to be updated and re-uploaded, without any mold adjustments required, enabling “instant modification and instant production.”

Application Scenarios: Specialized Domain Divisions

Based on the above differences, the two processes have formed a clear “domain division” in practical applications, each adapting to the needs of different industries.

Traditional casting, with its advantages in large-scale and high-volume production, is widely used in fields where part complexity requirements are low, but certain demands for size and strength exist:

- Transportation Sector: Railway track components, ship hulls and propellers, large truck engine blocks, etc. These parts are large in size, have relatively simple structures, and require mass production. Casting can meet the demand at a low cost.

- Construction and Construction Machinery Sector: Bridge load-bearing components, crane bases, excavator buckets, etc. These parts need to withstand heavy loads, and casting can achieve high strength by optimizing the material formula while meeting the large-size manufacturing requirements.

- Some Consumer Goods Sectors: Such as cast iron cookware, large metal furniture frames, etc. Mass production can significantly reduce costs, and complex designs are not required.

Metal 3D printing, on the other hand, shines in high-value-added, low-volume, and high-precision fields with its complex structure forming ability and short cycle advantages:

- Aerospace Sector: Turbine blades, engine combustion chambers, etc. These parts require complex internal cooling channels and have extremely high requirements for material performance and dimensional accuracy. 3D printing can achieve integrated forming, reducing assembly steps and enhancing reliability.

- Medical Field: Customized artificial joints, dental implants, etc. These need to be designed according to individual patient data, and the “personalized, low-volume” characteristics of 3D printing are a perfect fit.

- Industrial Prototyping and Low-Volume End-Use Parts: Functional prototypes in the new product development stage, rare spare parts required for equipment maintenance, etc. 3D printing can produce quickly without the need for molds, significantly shortening the R&D cycle and maintenance waiting time.

How Will Metal 3D Printing and Traditional Casting Develop in the Future? Will They Compete?

Despite the rapid development of metal 3D printing technology, with continuously expanding equipment capacity and an increasing range of material options (currently covering most mainstream metal materials), traditional casting has not been replaced. The cost-effectiveness and technical maturity of casting in manufacturing large-size and high-volume parts remain difficult for 3D printing to surpass in the short term. The relationship between the two is not one of pure competition but rather a trend of “synergistic coexistence” and innovation.

How Can Metal 3D Printing and Traditional Casting Achieve Synergistic Development?

Some enterprises have started using 3D printing technology to produce metal molds, which are then used in casting production. This model leverages the advantage of 3D printing in quickly forming complex molds while retaining the cost advantage of casting in mass part production, achieving a “1 + 1 > 2” effect.

How to Choose? Three Core Dimensions for Decision-Making

Choosing between metal 3D printing and traditional casting essentially involves a comprehensive consideration of three core dimensions: “design requirements, production scale, and delivery time”:

- If the part has a complex structure, high precision requirements, a small production quantity, and requires quick delivery, choose metal 3D printing.

- If the part is large in size, has a simple structure, requires high-volume production, and the delivery cycle requirement is not urgent, choose traditional casting.