You’ve probably seen many plastic products made through injection molding. But did you know that now metal can also be injection molded just like plastic?

This amazing process is called Metal Injection Molding, or MIM for short. It’s like the Transformers of metalworking, capable of producing metal parts with complex shapes.

What is Metal Injection Molding

Metal Injection Molding is an advanced manufacturing process that combines plastic injection molding and powder metallurgy technology.

Simply put, it involves mixing metal powder with special binders to create feedstock that looks like plastic pellets. Then using equipment similar to plastic injection molding machines, this feedstock is heated and injected into molds under high pressure.

The part taken out after cooling isn’t the final product yet. It needs to go through debinding and high-temperature sintering processes before becoming a real metal part.

Process Flow: Five Steps to Success

Step 1: Feedstock Preparation

Ultra-fine metal powder (5-20 microns) is mixed with polymer binders in specific proportions. This process is like making dough – it needs to be thoroughly mixed so every metal powder particle is coated with binder.

The final product is granular feedstock with good flowability, just like the plastic pellets we usually see.

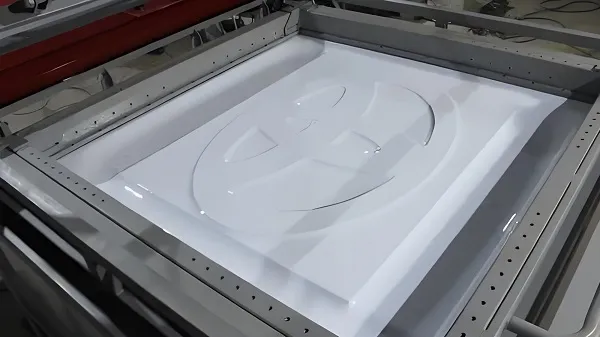

Step 2: Injection Molding

The prepared feedstock is fed into an injection molding machine. The machine heats the feedstock to around 200°C, at which point the binder melts and the entire mixture becomes as viscous as honey.

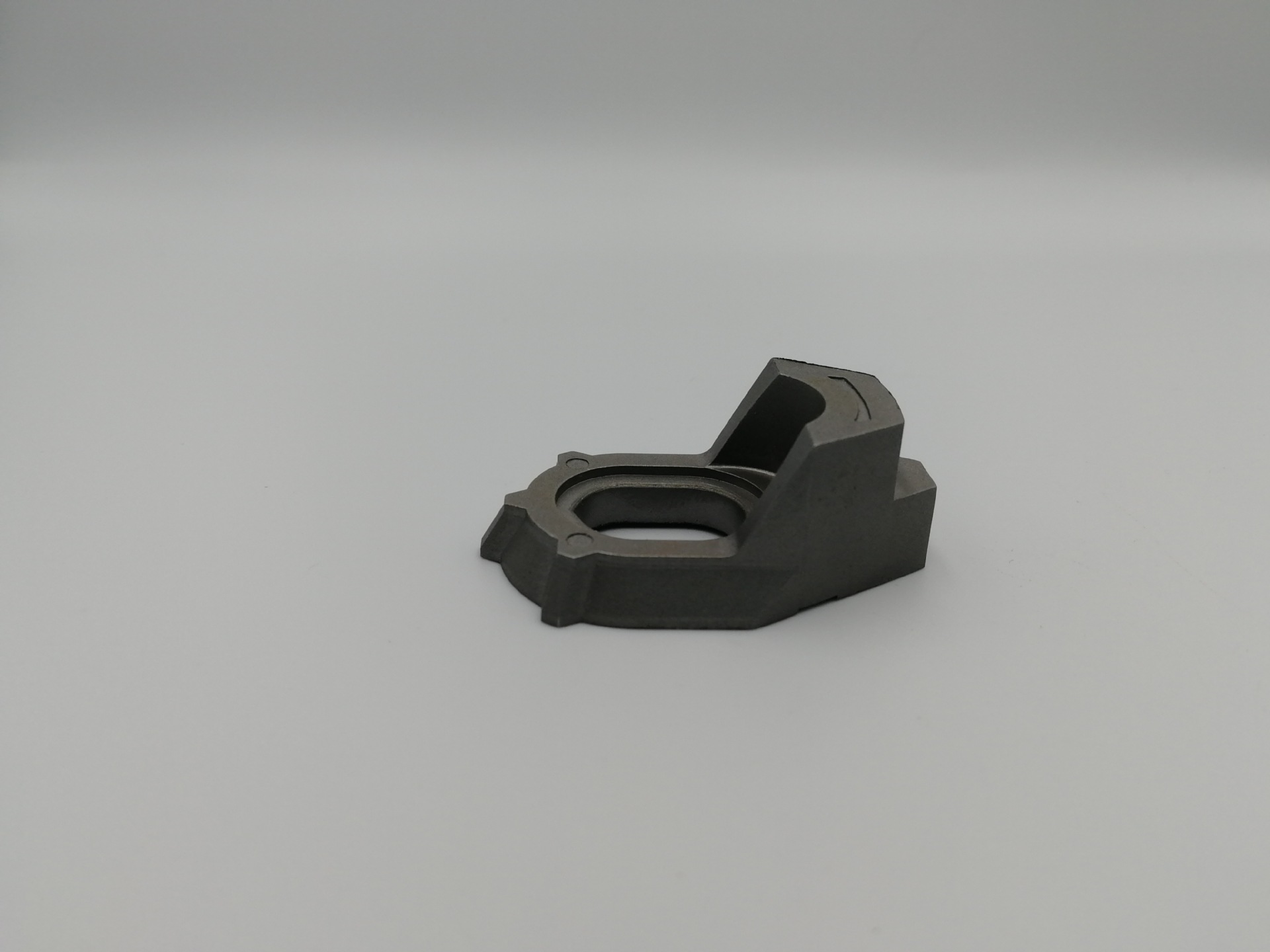

Then under high pressure, this “metal paste” is injected into precision molds. After cooling, the mold is opened to get a complex-shaped “green part”.

Step 3: Debinding Process

This step is crucial – the binder needs to be removed from the green part. Without removal, the part may deform or crack during subsequent high-temperature sintering.

Debinding usually uses solvent soaking or heating to remove most binders, leaving just a little to maintain the part’s shape.

Step 4: High-Temperature Sintering

The debound parts are placed in a high-temperature sintering furnace. At temperatures close to the metal’s melting point (usually 1300-1400°C), metal powder particles begin to fuse together.

During this process, the part shrinks by 15-20%, eventually forming a dense metal part with a density of over 95%.

Step 5: Post-Processing

Depending on product requirements, some subsequent processing may be needed. This could include size correction, heat treatment, surface polishing, electroplating, etc.

After these steps, a high-precision, high-performance metal part is completed.

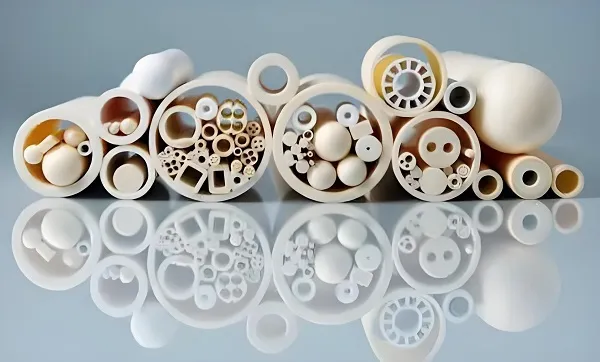

Material Variety: More Than Just One Metal

Metal Injection Molding can use various metal materials:

Stainless Steel Series: 304, 316, 17-4PH, etc., with good corrosion resistance

Titanium Alloys: Lightweight, high strength, good biocompatibility, commonly used in medical fields

Tungsten Alloys: High density, suitable for counterweight parts

Aluminum Alloys: Lightweight, good thermal conductivity

Copper Alloys: Good electrical conductivity, suitable for electronic parts

Other Materials: Tool steel, cobalt alloys, nickel-based alloys and other special materials

Why Choose Metal Injection Molding

Clear Advantages

Complex Shapes in One Step: Can produce complex structures that are difficult with traditional machining, such as internal cavities and complex curved surfaces

High Efficiency for Mass Production: Using mold forming, can achieve automated production with daily output of tens of thousands of pieces

High Material Utilization: Near-net shape forming with minimal material waste; gates and scrap can be recycled

Cost Advantage: For complex parts, costs are 30-50% lower than traditional machining

High Precision: Dimensional tolerances can be controlled within ±0.5%, with good surface finish

Limitations

Of course, this process isn’t universal:

Size Limitations: Usually suitable for small parts weighing between 5 grams and 200 grams

High Mold Costs: Initial mold investment is large, suitable for mass production

Long Production Cycle: From mold making to product delivery, the entire cycle is relatively long

Wide Applications: Needed in Various Industries

Consumer Electronics

Small precision parts for mobile phones: volume buttons, power buttons, SIM card trays, etc.

Smartwatch cases, strap buckles, sensor housings

Laptop hinges, heat sinks, brackets, etc.

**

Automotive Industry

Engine components: turbocharger impellers, valves, piston rings, etc.

Transmission systems: transmission gears, drive shafts, synchronizer hubs, etc.

Interior and exterior parts: center console buttons, emblems, grilles, etc.

Medical Devices

Orthopedic implants: artificial joints, bone screws, bone plates, etc.

Dental instruments: implants, crowns, bridges, etc.

Surgical instruments: tweezers, scissors, forceps and other precision tools

Aerospace

Aircraft engine blades, turbine disks, landing gear components

Satellite structural parts, antennas, sensors, etc.

These components require lightweight construction, high precision, and high reliability

Other Fields

Mechanical Industry: Various gears, cams, couplings, etc.

Watch and Jewelry: Watch cases, straps, jewelry accessories, etc.

Sports Goods: Golf club heads, arrowheads, etc.

Military Field: Gun parts, missile components, etc.

Technology Development Trends

Metal Injection Molding technology is constantly evolving:

Materials: Developing more types of metal materials and alloys

Process Optimization: Improving the stability and efficiency of debinding and sintering processes

Equipment Upgrades: Specialized equipment becoming more precise and intelligent

Application Expansion: Developing from traditional small parts to larger size, higher performance components

Comparison with Traditional Processes

Compared to Machining

Advantages: Can produce complex shapes, higher material utilization, lower costs

Disadvantages: Relatively lower dimensional accuracy, surface finish may require subsequent processing

Compared to Casting

Advantages: Higher dimensional accuracy, better surface quality, more uniform material properties

Disadvantages: Part size limitations, higher mold costs

Compared to Powder Metallurgy

Advantages: Can produce more complex shapes, higher density, better performance

Disadvantages: More complex process, relatively higher costs

Quality Control Points

Quality control in Metal Injection Molding is very important:

Material Control: Metal powder particle size, purity, and distribution must be stable

Process Parameters: Injection temperature, pressure, speed and other parameters must be precisely controlled

Debinding Control: Debinding rate and degree must be appropriate to avoid deformation

Sintering Control: Temperature curve and holding time must be precisely controlled

Dimensional Control: Considering sintering shrinkage, mold design must reserve shrinkage allowance

As an advanced manufacturing process, Metal Injection Molding is playing an increasingly important role in more and more fields. It not only solves many problems in traditional metal processing but also provides greater freedom for product design.

From the mobile phones we use every day to high-end aerospace equipment, from precision medical devices to durable automotive components, Metal Injection Molding technology is quietly changing our lives and industrial manufacturing methods.

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.