Craftsmanship Inheritance from Grip Feel to Safety

Hello everyone, I’m the Technical Director of Xiamen Gold Cattle. Today I want to share our expertise in the specialized field of custom CNC automotive steering wheel parts manufacturing. As the most direct connection between driver and vehicle, the steering wheel is not just a control tool but also a carrier of safety assurance and personal design. Over 26 years, we’ve focused on perfectly combining precision manufacturing with ergonomics to create a “human-vehicle integration” experience for every driver.

Steering Wheel Parts: The Overlooked Safety Core

Behind every seemingly simple steering wheel lies complex technology and strict safety standards:

- Global Market Size: The global automotive steering wheel and parts market reached (18.6 billion in 2024, projected to exceed )24 billion by 2028 with a 6.2% CAGR

- Safety Certifications: Must pass dual certifications of E-MARK ECE R12 (EU) and DOT FMVSS 203 (USA)

- Material Innovation: Lightweight materials like magnesium-aluminum alloy and carbon fiber increased from 35% to 68% usage

- Personal Design Trend: The personal steering wheel change market grows at over 15% annually, with 42% personal design rate for premium models

These figures show steering wheel components evolving from simple mechanical parts to intelligent, personalized safety systems.

Core Technologies: Precision Art in Every Detail

1. Skeleton Machining Technology: The Foundation of Safety

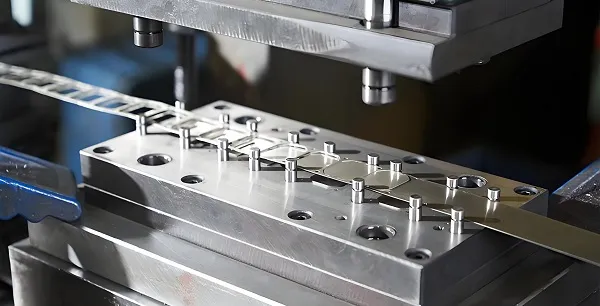

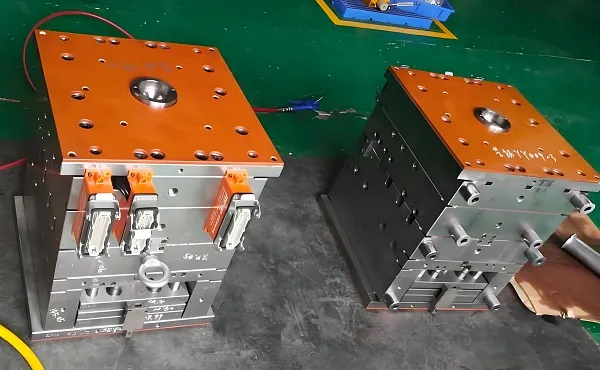

The steering wheel skeleton is the core load-bearing component. We use ASTM B94-17 magnesium-aluminum alloy standard with precision die-casting and CNC machining:

- Material Selection: AM50A magnesium-aluminum alloy, density 1.78g/cm³, tensile strength 230MPa

- Processing Precision: Contour tolerance ±0.05mm, hole position tolerance ±0.02mm

- Modal Performance: First-order frequency ≥83Hz, second-order frequency ≥110Hz

- Collision Energy Absorption: Axial energy absorption ≥150J, lateral energy absorption ≥80J

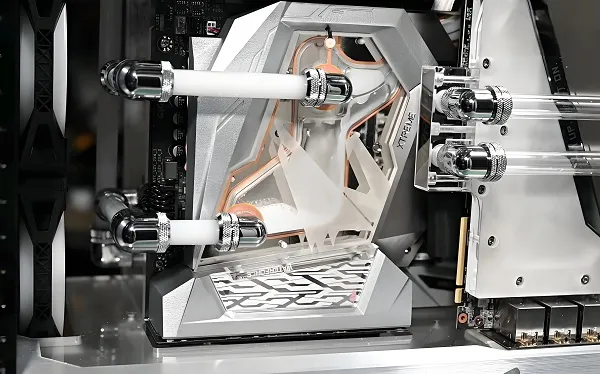

2. Multi-functional Button Integration: Bridge to Intelligent Interaction

Modern steering wheels have become intelligent interaction platforms. Our CNC machining ensures:

- Button Module Processing: 6061-T6 aluminum alloy with surface anodizing treatment

- Installation Precision: Button travel tolerance ±0.03mm, actuation force 150-250g

- Electrical Connection: Gold-plated contacts, contact resistance ≤50mΩ, lifespan ≥500,000 cycles

- Waterproof Rating: IP65 protection, meeting in-vehicle electronic equipment standards

3. Airbag Cover: The Guardian of Life

The airbag cover is the most critical safety component, manufactured strictly according to ISO 12097-2 standard:

- Material Requirements: Modified PP+EPDM-T20, Shore hardness 85±5 Shore D

- Deployment Performance: Burst pressure 50-80kPa within -30℃~80℃ temperature range

- Surface Treatment: Piano baking paint or matte texture, adhesion grade ≥4B

Assembly Precision: clearance fit with airbag module ≤0.5mm, flatness ≤0.3mm

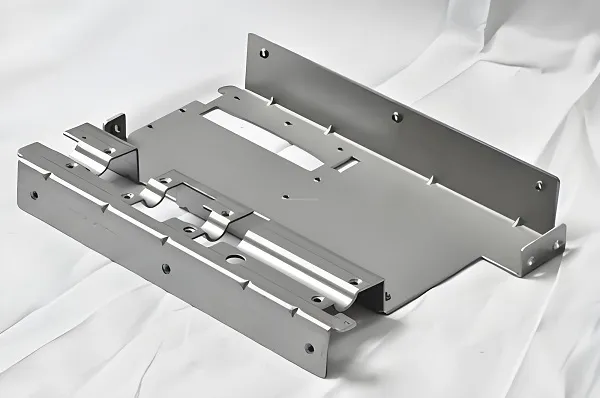

4. Personal Design Process: Fusion of Art and Technology

We combine CNC precision machining with personal design, where the cutting technology is a critical step:

- Carbon Fiber Wrapping: 3K carbon fiber weaving, epoxy resin impregnation, thickness 0.8-1.2mm

- Precision Cutting: Using high-speed CNC routers for complex shape metal cutting with ±0.01mm accuracy

- Alcantara Suede: Italian imported material, friction coefficient 0.65-0.75

- Laser Engraving: Precision ±0.01mm, depth 0.1-0.3mm, supporting complex patterns

- RGB Ambient Lighting: 16 million color options, brightness 500-1000cd/m²

Design Process: The Perfect Journey from Concept to Finished Product

Requirement Analysis Stage

- Vehicle Adaptation Confirmation: Determine parameters based on vehicle year, model, and configuration

- Functional Requirement Communication: Personalize audio control, cruise control, phone functions

- Material Selection Recommendations: Recommend suitable material combinations for usage scenarios

- Safety Standard Confirmation: Ensure all personal designs maintain original safety performance

Design and Development Stage

- 3D Modeling Design: Precise modeling using CATIA/Creo

- Finite Element Analysis: Modal analysis, strength analysis, collision simulation

- Ergonomic Optimization: Verify grip comfort and button layout logic

- Rendering Confirmation: Provide multi-angle renderings for customer approval

Processing and Manufacturing Stage

- CNC Precision Machining: 5-axis simultaneous machining center, precision ±0.005mm

- Cutting Process: High-precision metal cutting technology using advanced CNC cutting equipment

- Surface Treatment Processes: Anodizing, plating, painting, wrapping

- Assembly and Debugging: Functional testing, electrical connection testing, gap adjustment

- Quality Inspection: Coordinate measuring, modal testing, environmental testing

Quality Control: Safety Always Comes First

Raw Material Control

- Material selection: Strict supplier audit and material certification

- All metal materials provide material certificates and performance test reports

- Plastic materials meet VOC emission standards and combustion requirements

- Wrapping materials pass skin contact safety testing

Processing Process Control

- First article inspection and process patrol inspection for each operation

- 100% inspection of key dimensions using SPC statistical process control

- Full inspection of surface treatment layer thickness and adhesion

- Cutting process completion verification: Each cutting operation undergoes strict dimensional inspection before proceeding to next process

Problem-solving Techniques

We have developed specialized problem-solving techniques for common challenges:

- Thin Material Cutting: Using low-power laser with high-frequency pulse mode

- Hard Material Processing: Combining waterjet cutting with CNC machining

- Complex Shape Cutting: 3D laser cutting with 5-axis motion control

- Batch Consistency: Automated feeding systems and real-time monitoring

Finished Product Inspection Standards

- Dimensional Accuracy: Profile degree ≤0.1mm, position degree ≤0.05mm

- Function Testing: 100% testing of all button functions, response time ≤0.3 seconds

- Environmental Testing: -40℃~85℃ temperature cycling, 95% humidity testing

- Safety Certification: Pass ECE R12 and FMVSS 203 collision testing

Tracking Management

- Each batch has a unique tracking code

- Complete records of raw material batches, equipment, and operators

- Quality inspection data saved for at least 5 years

Typical Case: Custom Steering Wheel Born for the Track

Customer Requirements:

- Adapted for Porsche 911 GT3 racing car

- Weight reduction of over 30% to improve control response

- Integration of 12 custom function buttons

- Meet FIA racing safety standards

Our Solution:

- Material innovation: T700 carbon fiber prepreg with aviation-grade aluminum alloy bracket

- Precision Cutting: Custom metal cutting of carbon fiber sheets using CNC routers with 0.005mm accuracy

- Structural Optimization: Topology optimization design for lightweight strength

- Function Integration: Custom button layout for quick shifting and traction control

- Safety Design: Pass FIA 8855-1999 racing steering wheel safety certification

After 3 months of R&D and testing, we delivered this custom steering wheel. The cutting process completed with perfect precision, ensuring the complex carbon fiber structure met all performance requirements. Actual tests showed weight reduction from 3.2kg to 2.2kg (31.25% reduction), with 18% improved steering response speed.

Advanced Cutting Technologies

Laser Cutting

Laser cutting is our core technology for precision metal processing:

- Fiber Laser Technology: 1000W-4000W fiber laser cutting machines

- Precision: ±0.01mm positioning accuracy, 0.05mm cutting width

- Materials: Carbon steel, stainless steel, aluminum alloy up to 20mm thickness

- Advantages: No tool wear, high cutting speed, fine cutting edge

Waterjet Cutting

Waterjet cutting complements laser cutting for special materials:

- Abrasive Waterjet: 60,000 psi water pressure with garnet abrasive

- Material Versatility: Cutting metal, stone, glass, composites, and heat-sensitive materials

- Cold Cutting Process: No thermal distortion, ideal for precision parts

- Thickness Capacity: Up to 150mm for metal materials

Plasma Cutting

For thick metal plate processing:

- High-definition Plasma: Cutting accuracy ±0.1mm, surface roughness Ra 12.5μm

- Material Range: Carbon steel up to 150mm, stainless steel up to 100mm

- Cutting Speed: 3-5 times faster than flame cutting

- Cost Efficiency: Lower operating cost for thick plate processing

Ultrasonic Cutting

For soft materials and composites:

- Vibration Frequency: 20-40kHz ultrasonic vibration

- Materials: Carbon fiber composites, rubber, plastic, foam

- Cutting Quality: Clean edges without delamination

- Tool Life: Extended tool life due to reduced cutting force

Material Expertise: Mastering Various Materials

Metal Materials

We have deep expertise in metal cutting of various types:

- Carbon Steel: Q235, 45#, S45C with different carbon content

- Alloy Steel: 40Cr, 42CrMo, 38CrMoAl for high-strength applications

- Stainless Steel: 304, 316L, 430 with different corrosion resistance

- Aluminum Alloy: 6061, 7075, 5052 for lightweight applications

- Titanium Alloy: Ti-6Al-4V for high-strength lightweight components

Non-metal Materials

Our cutting technology also handles:

- Engineering Plastics: POM, PEEK, PA66, PC with glass fiber reinforcement

- Composite Materials: Carbon fiber, glass fiber, aramid fiber composites

- Ceramic Materials: Alumina ceramic, zirconia ceramic for high-temperature applications

- Natural Materials: Wood, stone, leather for decorative components

Material Preparation

Proper material preparation is critical for quality:

- Material Inspection: Chemical composition analysis, mechanical property testing

- Surface Preparation: Cleaning, degreasing, rust removal before cutting

- Cutting Optimization: Nesting optimization for material utilization

- Waste Management: Recycling and proper disposal of cutting waste

Conclusion: Trust in Your Hands

26 years of experience taught us that the steering wheel is more than a mechanical component—it’s the most intimate connection between driver and vehicle. Every turn carries safety promises; every button transmit convenience pursue;every material embody squality commitment.

In this rapidly changing era, we’ll continue our “safety first, quality foremost, innovation-driven” philosophy, using CNC precision machining and advanced cutting technology to create both safe and personalized steering wheel components.

If you have steering wheel design needs or ideas, we welcome in-depth technical exchanges. Let’s work together to enhance the driving experience with craftsmanship spirit.

Contact Us:

Looking forward to technical collaborations with you to steer the bright future of the automotive industry together!