1. Why Is Plastic Prototype Manufacturing a Necessity?

The traditional “mass production after mold creation” model is too sluggish for today’s fast-paced innovation. Data shows that the global plastic prototype manufacturing market reached $8.9 billion in 2024, driven by three critical demands:

- Risk Reduction: Startups and established companies alike use prototypes to validate designs. For example, a smartwatch brand reduced return rates by 15% by testing 500 prototypes of a new strap material.

- Speed-to-Market: Prototyping slashes development cycles. A drone company cut its product launch time from 12 months to 3 months using rapid prototyping.

- Cost Efficiency: Avoiding costly mold revisions, 75% of automotive suppliers now use prototypes to test part functionality before mass production.

2. Technology Breakthroughs Redefining Possibilities

Material Innovation

- High-Performance Polymers: Materials like PEEK (with a melting point of 343°C) enable prototypes for aerospace components, achieving 90% of final product strength.

- Bio-Based Plastics: Cornstarch-based PLA reduces carbon footprint by 30% while maintaining printability.

Precision Manufacturing

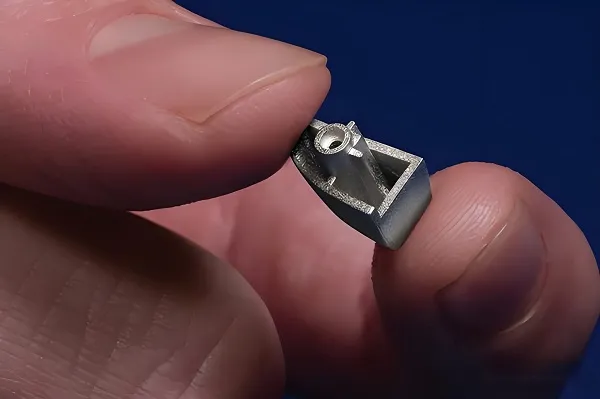

- CNC Machining: Achieves ±0.01mm accuracy for microfluidic medical devices.

- 3D Printing: Multi-material printing (e.g., rigid-flexible combinations) mimics final product performance, reducing testing iterations by 50%.

Digital Validation

- CAE Simulation: Predicts warpage and stress distribution, cutting physical trials by 60%. A home appliance brand improved part yield from 85% to 97% using simulation.

3. Industry Applications: From Wearables to Aerospace

- Consumer Electronics:

- A Japanese earphone brand produced 5,000 noise-canceling tips with 99.3% yield using “1-mold-4-cavity” prototyping.

- Transparent smartphone casings are now validated via in-mold electronics (IME) prototypes to test touch sensitivity.

- Automotive:

- Tesla suppliers use aluminum-insert prototypes for charging port housings, reducing weight by 12g per unit.

- Crash-test dummy components are 3D-printed with silicone-like materials to simulate human tissue.

- Healthcare:

- Surgical tool prototypes made from USP Class VI-certified resins undergo 1,000+ sterilization cycles.

4. Future Trends: Smarter and Greener

- AI-Driven Optimization: Machine learning predicts optimal parameters (e.g., melt temperature, cooling rate), reducing setup time from 3 days to 4 hours.

- Circular Economy: 30% of manufacturers now use recycled PETG for prototypes, cutting material costs by 18%.

- Hybrid Prototyping: Combining 3D printing and CNC machining achieves both surface finish (±0.5μm roughness) and structural integrity.

5. Supplier Selection Checklist

- Technical Capability: Verify machine precision (e.g., ±0.05mm for medical devices).

- Material Portfolio: Ensure access to 30+ polymers, including FDA-compliant options.

- Certifications: Prioritize ISO 13485 (medical) or IATF 16949 (automotive) certified partners.

Key Quality Metrics

| Parameter | Standard | Example Application |

|---|---|---|

| Dimensional Accuracy | ±0.05mm | Micro-connectors |

| Tensile Strength | ≥40MPa (ABS) | Load-bearing brackets |

| Surface Roughness | Ra ≤1.6μm | Optical lens housings |

Conclusion

Plastic prototype manufacturing is no longer a “nice-to-have” but a strategic tool for innovation. With advancements in materials, simulation, and sustainability, businesses can iterate faster, fail smarter, and launch confidently.