Industry Standards and Certifications

Global Quality Management Standards

IATF 16949 (ISO/TS 16949)

- Scope: Global automotive industry quality management system

- Requirements: Based on ISO 9001 with automotive-specific enhancements

- Focus: Defect prevention, reduction of variation and waste

- Certification: Valid for 3 years with annual surveillance audits

VDA 6.x Series

- VDA 6.1: Quality management system for automotive suppliers

- VDA 6.3: Process audit standard for manufacturing processes

- VDA 6.4: Quality management for production equipment

- VDA 6.5: Product audit requirements

CAPA Certification

- Purpose: Independent quality assurance for replacement parts

- Testing: Stringent performance and safety evaluations

- Recognition: Accepted by insurance companies and regulatory bodies

- Marking: Distinctive yellow and blue quality seal

Performance Testing Standards

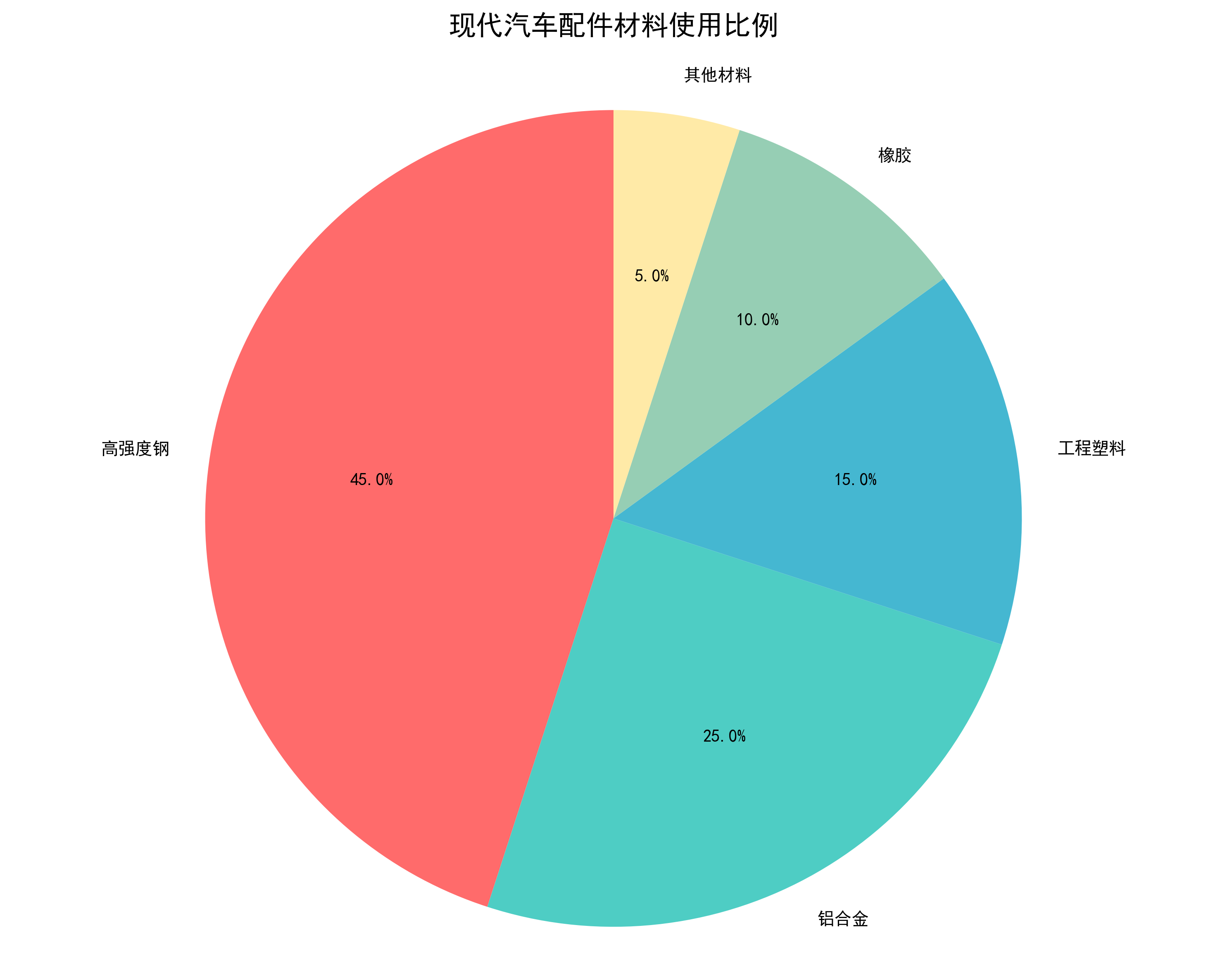

Material Testing

- ISO 14284: Chemical analysis of metallic materials

- ISO 6892: Tensile testing of metallic materials

- ISO 945: Metallographic examination of steel

Dimensional Inspection

- ISO 1101: Geometrical product specifications

- ISO 4287: Surface texture measurement

- ASME Y14.5: Dimensioning and tolerancing

Environmental Testing

- ISO 9227: Corrosion testing (salt spray)

- ISO 16750: Environmental conditions for electrical/electronic equipment

- ISO 18436: Vibration and shock testing

Performance Comparison and Selection Criteria

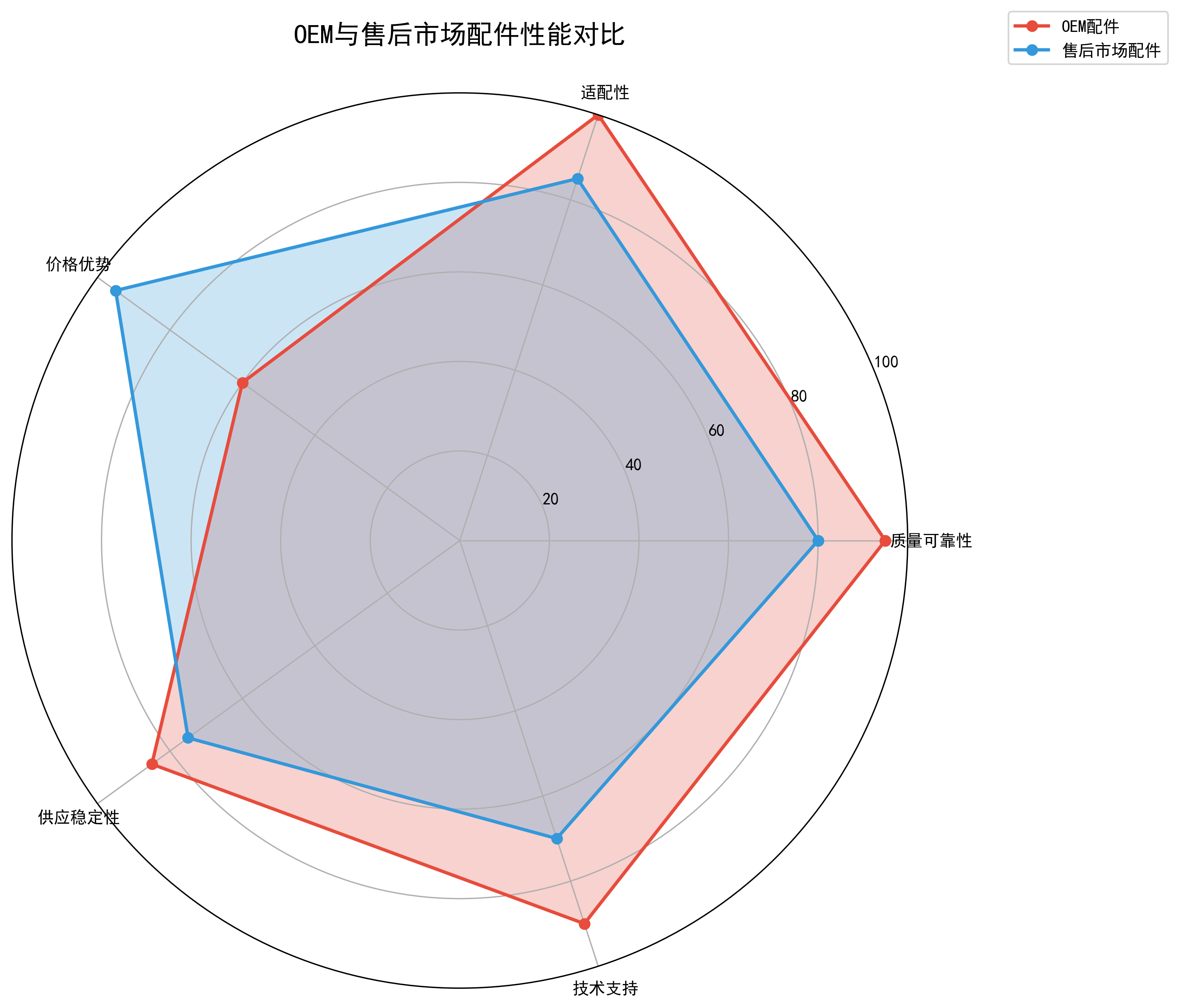

OEM vs. Aftermarket Parts

- OEM (Original Equipment Manufacturer): 100% compatibility with exact specifications, typically 30-50% higher cost

- Brand-certified parts: ISO/TS16949 certified, 20-30% cost savings vs. OEM

- Aftermarket parts: Wide price range with variable quality standards

Quality Assessment Parameters

- Certifications: ISO, CAPA, and industry-specific standards

- Material composition: Chemical analysis for authenticity

- Dimensional accuracy: Precision measurements against specifications

- Performance testing: Durability, strength, and functionality validation

Selection Guidelines

- Critical components: Use OEM or brand-certified parts for safety systems

- Non-critical parts: Consider aftermarket options for cost savings

- Compatibility: Verify fitment with vehicle make, model, and year

- Warranty coverage: Protect your investment with proper guarantees

Choosing the Right Supplier

When selecting an auto spare parts supplier, consider:

- Manufacturing experience: Years of expertise in the industry

- Quality control systems: Comprehensive testing and inspection processes

- Technical capabilities: Advanced equipment and engineering expertise

- Customization options: Ability to meet specific requirements

Xiamen Goldcattle: Your Trusted Partner

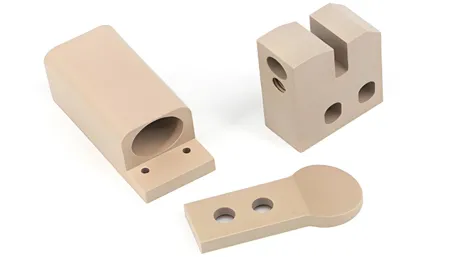

For over 26 years, Xiamen Goldcattle has been a leading provider of precision auto spare parts. As a national high-tech enterprise, we specialize in CNC machining, injection molding, and stamping services with tolerance levels as tight as ±0.005mm. Our capabilities include:

- Custom automotive parts: Tailored solutions for various vehicle applications

- Complete manufacturing solutions: From design to production and assembly

- Advanced equipment: 100+ processing machines with 5-axis capabilities

- Quality assurance: ISO-certified processes and rigorous testing protocols

Whether you need engine components, suspension parts, or custom solutions, Xiamen Goldcattle delivers the precision and reliability your vehicles deserve. Visit www.xmgoldcattle.com to explore our comprehensive range of automotive spare parts and manufacturing services.