From Prototyping to Mass Production – Xiamen Goldcattle’s 26 Years of Expertise

Precision injection molding in controlled environment for high-quality plastic parts

Tired of Compromising on Plastic Part Quality?

Are you frustrated with product development challenges: off-the-shelf plastic parts lacking precision, overwhelming inventory pressure from large minimum order quantities, or exorbitant mold costs when making design changes?

Or have you experienced injection molded parts with deformation, excessive flash, and constant assembly issues that slow down your production?

A Real Goldcattle Success Story

“In 2025, a new energy vehicle client came to us with battery housing injection molded parts suffering from excessive air bubbles and uneven wall thickness, causing waterproofing failures. Using precision injection molding machines + vacuum-assisted molding, we controlled wall thickness to ±0.02mm and reduced bubble rate to 0.1%. The client reported: ‘Product reliability improved by 25%, and sales took off immediately.'”

Today, Xiamen Goldcattle takes you on a comprehensive exploration of custom injection molding services – from material selection to mold optimization, this article helps you avoid all pitfalls and achieve efficient, low-cost production.

1. What is Custom Injection Molding Service?

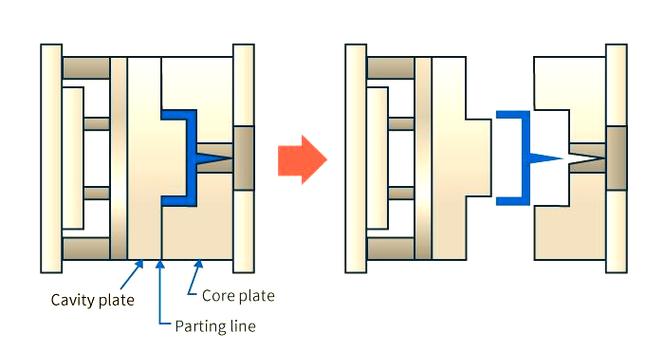

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity at high pressure, then cooled and solidified to produce plastic parts with complex shapes and high precision.

Common custom injection molded parts include:

- Product enclosures and housings

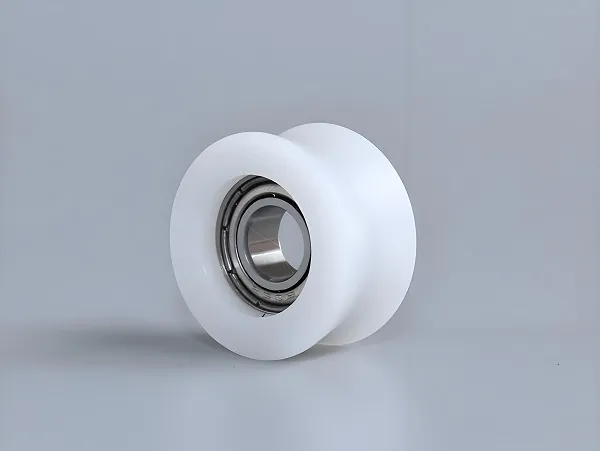

- Gears, bearings, and mechanical components

- Buttons, knobs, and control elements

- Medical device components

- Automotive interior and exterior parts

- Consumer electronics parts

Goldcattle Advantage

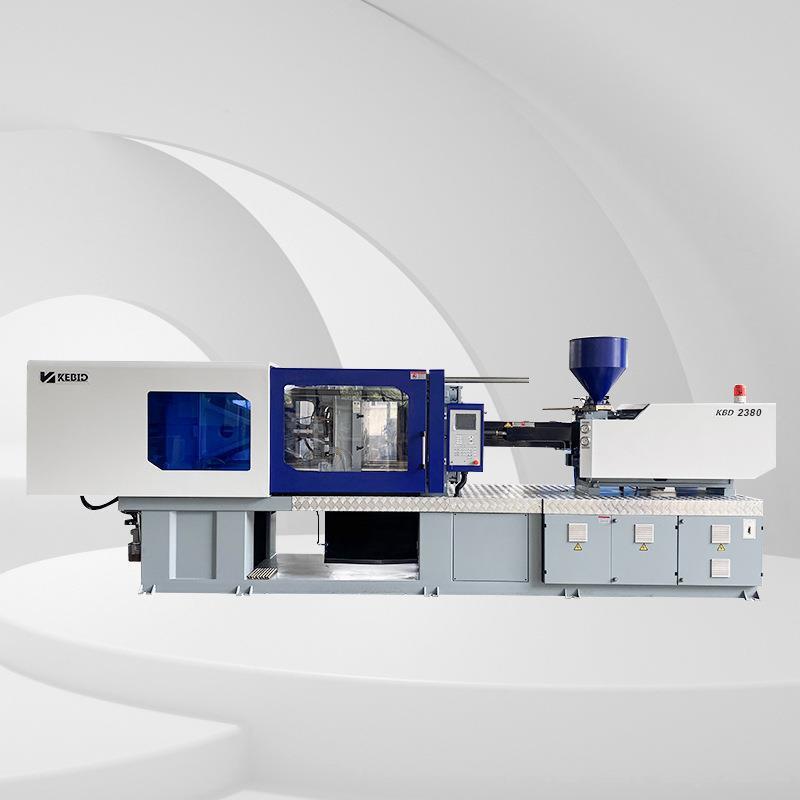

“We use Haitian/Engel precision injection molding machines + CAE simulation software, ensuring first-time molding success rate >95% with tolerance control of ±0.02-0.05mm and surface finish Ra0.8-1.6μm.”

High-precision injection molding machine for complex plastic parts

Standard vs Custom Injection Molding

| Feature | Standard Injection Molding | Custom Injection Molding |

|---|---|---|

| Minimum Order | 10,000+ pieces | 1-5,000 pieces |

| Design Flexibility | <10% design changes | Unlimited design iterations |

| Materials | <5 standard materials | 50+ engineering plastics |

| Lead Time | 45-60 days | 7-30 days |

2. Why Choose Custom Injection Molding Services?

The Pain Points of Traditional Injection Molding

High Mold Costs

- • Mold costs $5,000-$20,000

- • Small orders not cost-effective

- • Design changes require new molds

Quality Issues

- • Low precision, poor fitment

- • Warping and shrinkage problems

- • Assembly failures and rework

Material Limitations

- • Limited material options

- • No specialty materials

- • Can’t meet medical/automotive specs

The Benefits of Custom Injection Molding

| Benefit | Description | Goldcattle Example |

|---|---|---|

| Flexibility | Small batch production, rapid iterations | Medical housing: 7 days from prototype to production |

| Precision | Shrinkage control <0.5% | PC lens housing, tolerance ±0.03mm |

| Material Variety | ABS/PC/PA/PEEK and more | Automotive interior, UL94-V0 flame retardant |

| Cost Optimization | DFM optimization reduces waste by 15% | Customer feedback: 20% lead time reduction |

Another Real Success Story

“An electronics client had severe warping issues with their injection molded parts. We optimized mold cooling + CAE simulation, reducing warpage from 5% to 0.2%. Their assembly yield improved from 85% to 99.5%.”

3. Key Materials & Processes for Custom Injection Molding

Recommended Materials

ABS/PC Blends

High gloss, impact resistant, good dimensional stability

Ideal for: Instrument panels, enclosures, consumer products

PA66 (Nylon)

Wear resistant, high temperature resistant, self-lubricating

Ideal for: Gears, bearings, mechanical components

PEEK

Medical grade, chemical resistant, high temperature stable

Ideal for: Implants, valves, medical devices

Various plastic material pellets for injection molding

Key Processes & Parameters

Mold Design

CAE simulation for flow and cooling analysis

Injection Parameters

Temperature: 200-300°C, Pressure: 100-150MPa

Post-Processing

Deflashing, painting, assembly, testing

Quality Control

Dimensional inspection, material testing, functional testing

Goldcattle Custom Injection Molding Process

Goldcattle Technical Advantage

“We use vacuum assistance + multi-cavity molds, achieving bubble/defect rate <0.1%. Temperature-controlled workshops ensure stable shrinkage rates throughout production.”

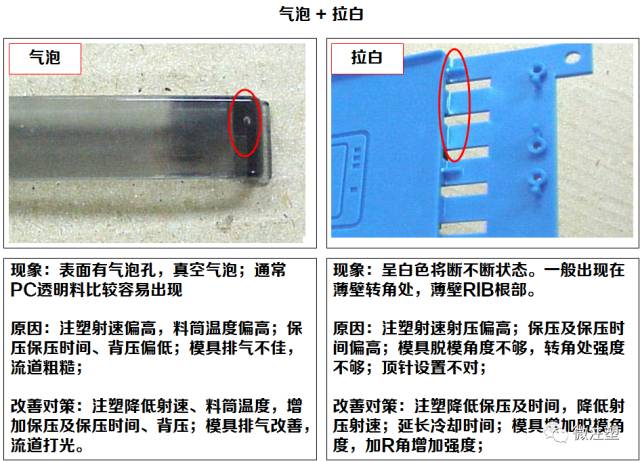

Common Defects and Solutions

Common defects: Air bubbles, sink marks, warpage, flash. Our CAE simulation identifies and prevents these issues before production.

4. Real Custom Injection Molding Cases

Medical Device Component

A medical device company needed custom PEEK syringe barrels with strict biocompatibility requirements and precise wall thickness control.

Project Requirements

- • FDA biocompatibility certification

- • Wall thickness tolerance: ±0.02mm

- • Surface finish: Ra0.8μm

- • Zero defects in critical areas

Results

Successfully passed FDA certification, wall thickness variation controlled to 0.015mm, defect rate <0.01%. The client’s product reliability improved by 30%.

Precision injection molded medical components

Automotive Interior Part

Automotive interior plastic components

An automotive manufacturer required ABS+PC instrument panels with flame retardant properties, high gloss finish, and strict dimensional control for a new electric vehicle model.

Key Achievements

- • UL94-V0 flame retardant certification

- • High gloss surface finish

- • Batch size: 5,000 pieces

- • Defect rate: 0.05%

Consumer Electronics Part

A consumer electronics brand needed TPU phone cases with custom textures and soft-touch finish. They required rapid prototyping and multiple design iterations.

Project Highlights

- • TPU material with soft-touch finish

- • Custom texture patterns

- • 3 design iterations

- • 7-day sample delivery

Colorful injection molded consumer products

5. How to Launch Your Custom Injection Molding Project Efficiently?

Follow these 5 steps to ensure your custom injection molding project runs smoothly and efficiently:

Step 1: Requirements Assessment

Provide CAD/STP drawings + material specifications + quantity requirements.

Step 2: DFM Feedback

We provide free design optimization, reducing mold costs by 10-20%.

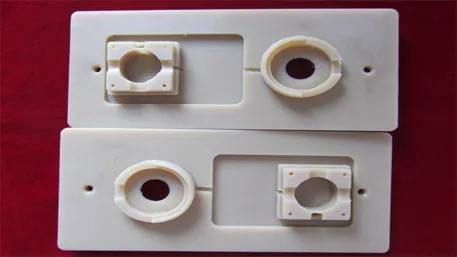

Step 3: Mold Trial

Rapid prototyping and verification of design and quality.

Step 4: Production & QC

100% inspection, SGS certification, and quality reports.

Step 5: Delivery & After-sales

Global logistics, 1-year warranty, and technical support.

Critical Pitfalls to Avoid

❌ Avoid

Suppliers without CAE simulation – prone to deformation issues

✅ Choose

Suppliers with medical/automotive certifications for reliability

Goldcattle’s temperature-controlled workshop ensures consistent molding quality

6. Frequently Asked Questions

Ready to Elevate Your Plastic Parts Production?

Custom injection molding services transform your products from ‘usable’ to ‘perfect’ – efficient, precise, and low-risk manufacturing that drives your business success.

Get Your Free Custom Injection Molding Consultation

Upload your CAD drawing for a fast DFM review and sample plan. We’ll respond within 24 hours!

Or contact us directly:

Email: charlie@plasticmetalparts.com

WhatsApp/WeChat: +86-18150097490