When it comes to versatile industrial materials, plastic is in a league of its own. It’s lightweight, chemical-resistant, and comes in endless formulations to match specific needs—no wonder it’s essential in everything from medical devices to consumer electronics and automotive components. At Xiamen Goldcattle, we’ve honed our plastic machining expertise over a decade, serving clients across the U.S. and Europe with precision parts that meet the tightest specifications. Whether you need a one-off prototype or large production runs, we deliver consistent quality with quick turnaround times.

Why Plastic is Ideal for CNC Machining

Experienced manufacturers know plastic offers unique advantages for CNC machining:

- Exceptional strength-to-weight ratio, perfect for reducing overall product weight

- Natural resistance to chemicals, moisture, and corrosion—ideal for harsh environments

- Excellent electrical insulation properties, making it a staple in electronics

- Smooth machinability that produces clean edges and tight tolerances without excessive tool wear

- Wide range of material options to match specific needs like heat resistance or flexibility

From intricate components to durable structural parts, plastic delivers performance where metal might be overkill or impractical.

Our Plastic Machining Capabilities

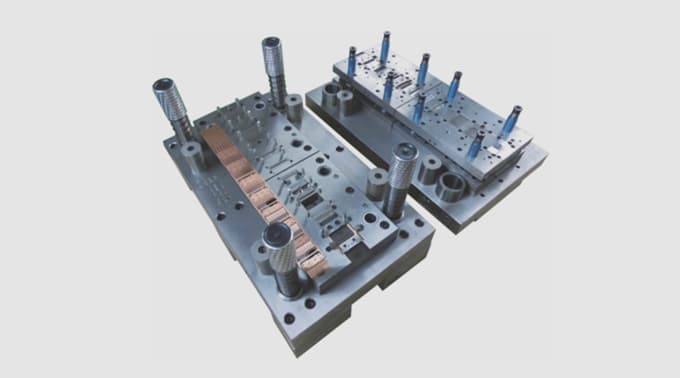

We handle every stage of plastic part production, from design to finished product:

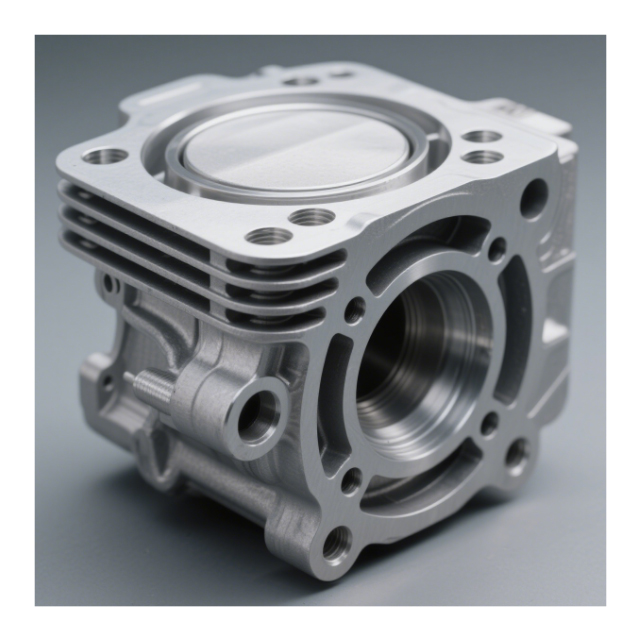

Basic CNC milling and turning are just the beginning—our 3-axis and 5-axis machining centers excel at complex plastic geometries. The advantage of 5-axis machining? It eliminates multiple setups for parts with angled features or complex curves, reducing errors and ensuring better consistency. We regularly achieve tolerances as tight as ±0.01mm, even on delicate plastic components that require careful handling.

Our shop features top-tier equipment: Haas and Mazak CNC systems paired with high-speed spindles (up to 20,000 RPM) specifically calibrated for plastic machining. We use carbide tools with special geometries to prevent common plastic issues like chipping, melting, or burring. For slippery materials like PTFE or Delrin, we’ve developed specialized fixturing techniques to ensure secure holding during machining.

Order flexibility is our specialty—we happily take on single prototypes and scale up to 10,000+ unit production runs. Need samples fast? Simple parts can be ready in 24–48 hours, with most prototypes delivered within 5 days.

We also offer in-house finishing services: precision polishing for optical clarity, custom color matching, and protective coatings for enhanced durability. Whatever your plastic part requirements, our equipment and expertise ensure a perfect finish every time.

The Plastic Materials We Work With

We stock a comprehensive range of engineering plastics to meet diverse industry needs:

ABS is our go-to for consumer products and enclosures—it’s strong, impact-resistant, and easy to finish

Nylon (PA) offers excellent wear resistance, making it ideal for gears and moving parts

POM (Delrin) provides low friction and dimensional stability, perfect for precision mechanical components

PEEK stands out for high-temperature resistance and biocompatibility—essential for medical and aerospace use

PTFE (Teflon) delivers unmatched chemical resistance and low friction for specialized applications

We also work with acrylic, polycarbonate, HDPE, and custom formulations—just let us know your material requirements.

Quality Control That Leaves Nothing to Chance

In plastic machining, precision and consistency are non-negotiable—that’s why we implement rigorous quality measures:

Our ISO 9001:2015 certified processes ensure every part meets your specifications

We source only certified materials with full traceability, including RoHS-compliant and medical-grade options

Our climate-controlled facility (maintained at 21±1℃) prevents material expansion/contraction during machining

Every batch undergoes inspection with our CMM (Coordinate Measuring Machine) for micron-level accuracy

In-process checks catch potential issues early, from dimensional variations to surface imperfections

You’ll receive parts that not only meet but exceed your quality expectations, with documentation to verify compliance.

Industries We Serve with Confidence

We’ve developed deep expertise across industries with unique plastic part requirements:

Medical devices (sterilizable components, instrument housings)

Electronics (insulators, connectors, enclosures)

Automotive (interior components, sensor housings, wear parts)

Aerospace (lightweight structural parts, fluid system components)

Consumer products (ergonomic handles, decorative trim, functional parts)

No matter your industry, we understand the specific standards and performance needs that matter most to your application.

Real-World Plastic Machining Success Stories

Talk is cheap—here are some projects we’re proud to stand behind:

Medical Device Components

A U.S. medical equipment manufacturer needed precision PEEK surgical instrument parts with ±0.005mm tolerances and biocompatibility certification. Their previous supplier struggled with material consistency and surface finish. We used medical-grade PEEK and specialized toolpaths to maintain tight tolerances, achieving a mirror finish that met USP Class VI requirements. We now supply 5,000+ units monthly with zero defects.

Electronic Enclosures

A European electronics firm required custom ABS enclosures with complex internal ribs for heat dissipation. They needed tight dimensional control to ensure proper fit with internal components. Using our 5-axis machining center, we produced the enclosures in a single setup, eliminating assembly errors. Our in-house painting matched their exact Pantone color, and the final parts reduced their assembly time by 30%.

Automotive Sensor Housings

A major automaker needed nylon sensor housings resistant to engine bay temperatures and automotive fluids. Their original design had thin walls that warped during machining. We suggested design modifications to improve rigidity and used stabilized nylon 6/6 with specialized cooling during machining. The final parts passed 500+ hours of thermal cycling tests and are now in production for their electric vehicle line.

Why Clients Trust Us for Plastic Machining

After 26+ years in the business, we’ve built our reputation on these core strengths:

- We understand plastic’s unique properties—no more generic machining approaches that cause defects

- Our engineering team provides DFM (Design for Manufacturability) feedback to optimize your parts before production

- Dedicated support teams for U.S. and European clients handle time zones, standards, and logistics seamlessly

- We treat small prototype orders with the same care as large production runs

- Fast response times (usually within 4 hours) and transparent communication throughout your project

Ready for Your Plastic Part Quote?

Have a custom plastic component in mind? Send us your 3D models or technical drawings anytime. Our plastic machining specialists will provide a detailed quote within 24 hours, including material recommendations and design optimization suggestions. Whatever your question or requirement, we’re here to make your plastic machining project a success.