Custom Child Safety Plastic Caps E-commerce Content

|

Service Item

|

Details

|

Technical Parameters

|

Delivery Time

|

|

Safety Structure Design

|

Dual-action opening mechanism, child-resistant structure

|

Push+rotate, slide-align designChild opening force ≥5N·m

|

Design: 3-5 daysPrototyping: 7-10 days

|

|

Material Selection

|

Food-grade plastic, safe and non-toxic

|

HDPE, PP, food-grade siliconeCompliant with GB 4806 standard

|

Based on material inventory

|

|

Size Customization

|

Standard diameters and special sizes

|

28mm, 30mm, 38mm standard diametersCustom special sizes available

|

Based on drawing requirements

|

|

Surface Treatment

|

Anti-slip texture, warning label printing

|

0.3mm deep anti-slip textureFluorescent warning color printing

|

2-3 days

|

|

Safety Certification

|

Child safety testing, food contact certification

|

ISO 8317, ASTM D3475 certification85% children cannot open within 5 minutes

|

Certification: 10-15 days

|

|

Mass Production

|

Small batch trial to large-scale production

|

Monthly capacity 500,000 unitsCycle life ≥5000 times

|

Mass production: 15-25 days

|

Description

Product Details Page Content

Professional Custom Child Safety Plastic Caps

Safety Protection, Thoughtful Design

We specialize in providing high-quality custom child safety plastic cap services, utilizing advanced dual-action opening technology and food-grade materials to deliver reliable child protection solutions for pharmaceuticals, chemicals, cleaning agents, cosmetics and other products.

Core Safety Technology

Dual Protection Design

- Dual-Action Opening Mechanism: Push+rotate or slide-align design effectively prevents children from opening

- Scientific Force Design: Child opening force ≥5N·m, adult operating force 0.6-1.2N·m, balancing safety and convenience

- Intelligent Locking Structure: Ratchet locking system ensures automatic locking with each closure

Strict Safety Standards

- International Certification: Compliant with ISO 8317, ASTM D3475 child safety standards

- Test Verification: 85% children cannot open within 5 minutes, 90% adults can operate easily

- Cycle Durability: ≥5000 opening-closing tests, seal performance degradation ≤3%

Material Safety Assurance

Food-Grade Materials

- Safe Materials: HDPE, PP and other food-grade plastics, non-toxic and odorless

- Health Certification: Compliant with GB 4806 food contact material safety standard

- Hazardous Substance Control: Strict restriction on migration of harmful substances such as phthalates

Structural Reinforcement Design

- Reinforcement Ring Design: Wall thickness ≥1.5mm, deformation resistance ≥15kg

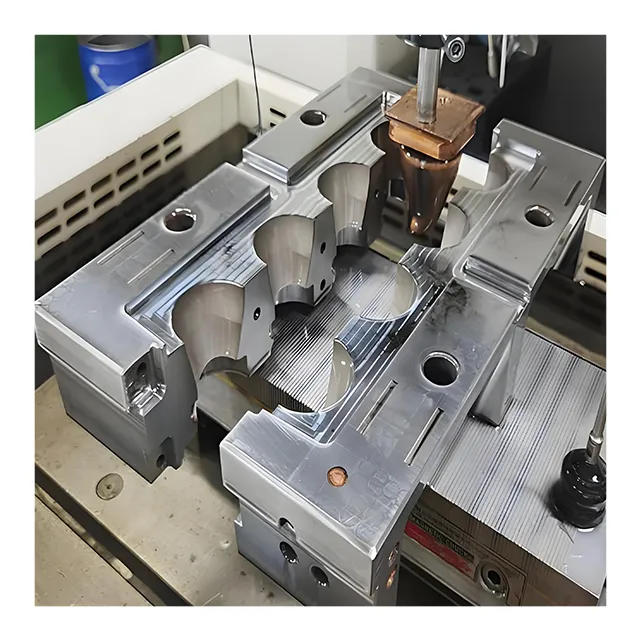

- Guide Tooth System: 8±1 teeth precision design, tooth height 1.2mm, spacing error ≤0.02mm

- Sealing Performance: Silicone sealing gasket ensures product sealing and shelf life

Humanized Design Elements

Anti-Slip Texture Treatment

- 0.3mm deep V-shaped anti-slip grooves, friction coefficient ≥0.35

- Suitable for wet hand operation, improving usability

Visual Warning System

- Fluorescent orange warning band, coverage ≥30%

- Clear operation guide markings, ergonomically designed

Tactile Identification Design

- 2mm diameter tactile warning bumps

- Circular array layout for easy blind operation identification

Application Fields

Pharmaceutical Packaging

- Child safety caps for children’s medication

- Prescription drug protection packaging

- Vitamin supplement bottle caps

Household Chemicals

- Cleaning agent safety caps

- Disinfectant protection packaging

- Laundry detergent child safety caps

Personal Care

- Cosmetic safety caps

- Oral care product caps

- Hair dye protection packaging

Food and Beverage

- Functional beverage bottle caps

- Condiment safety caps

- Health product packaging caps

Customization Service Process

- Requirement Analysis – Professional designers analyze your product characteristics and safety requirements

- Solution Design – Provide 2-3 sets of safety structure design solutions for selection

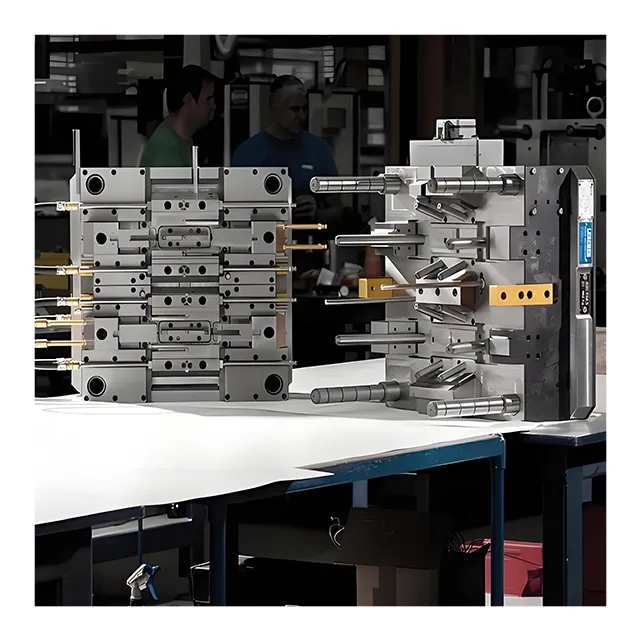

- Prototype Production – Complete prototype production and preliminary testing within 7-10 days

- Safety Certification – Conduct child safety testing and food contact certification

- Mass Production – Fully automated production line ensures quality consistency

- Finished Product Delivery – Packaging and transportation with after-sales technical support

Quality Assurance System

- Safety Certification: Passed ISO 8317, ASTM D3475 international certifications

- Material Traceability: Complete raw material traceability system

- Full Inspection System: 100% product inspection ensures each cap meets standards

- After-Sales Support: Provide product usage training and technical support

Choose our child safety caps to add the most reliable safety protection to your products!