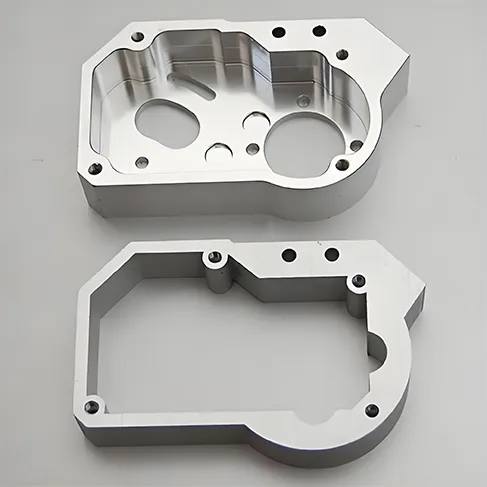

custom cnc machining milling parts components aluminium alloy cnc parts

Place of Origin : Fujian, China

Type : DRILLING, Milling, Turning, Wire EDM

Micro Machining or Not : Micro Machining

Model Number : CMP-241

Brand Name : JSD

Product name : custom cnc machining milling parts

Material : Customers’ Requirement

Surface treatment : Painting\Powder Coating\Plating\Polishing

Equipment : 3/4/5 Axis CNC Machining Center

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Certification : ISO9001

MOQ : 1 Piece

Description

1. Selected materials, quality assurance

Diversified material selection: the CNC machined parts we provide are made of a variety of high-quality materials, including aluminum alloy, stainless steel, titanium alloy, brass, and high-performance plastics. Each material is strictly screened to ensure that its physical properties, corrosion resistance and machining adaptability meet customer needs.

Material certification: All materials are sourced from well-known suppliers at home and abroad, and comply with international material standards, such as ASTM, DIN, JIS, etc., to ensure the traceability and quality reliability of the materials.

2.Precision design, customized service

Three-dimensional modeling and simulation: Using advanced CAD/CAM software for three-dimensional modeling, we pre-evaluate the structural strength, assembly compatibility and processing feasibility of the parts through simulation technology to ensure precise and error-free design.

Personalized customization: Provide one-on-one customer consulting services, personalized design according to the specific needs of customers, such as size, shape, hole layout, etc., to meet all kinds of customization needs from simple to complex structures.

3.Core role, efficient application

Core of mechanical components: CNC machined parts are widely used in mechanical equipment, automation equipment, automobile manufacturing, aerospace and other fields, as key components, such as drive shafts, gears, connectors, etc., to ensure the stable operation and efficient performance of the equipment.

Functional realization of the key: accurate dimensional control and surface treatment technology (such as sandblasting, anodizing, plating, etc.) enables the parts to accurately match the assembly requirements, to achieve specific functions, such as sealing, conductive, wear-resistant and so on.

4. Significant advantages, customers preferred

High-precision machining: The use of advanced CNC machining centers, combined with precision measuring tools, ensures that the parts are machined to an accuracy of ±0.01mm to meet high-precision assembly requirements.

Rapid delivery: Efficient automated production lines and flexible production scheduling system greatly shorten the production cycle, even for small quantities or urgent orders can be quickly responded to ensure on-time delivery.

Cost control: Through optimizing the production process and bulk purchasing of raw materials, we can effectively control the production cost and provide cost-effective CNC machined parts solutions for our customers.

After-sales service: Provide professional after-sales service team, quick response and processing of customer feedback problems, provide technical support, parts replacement and other comprehensive services to ensure customer satisfaction.