Description

Processing Capabilities

Number of Axes: Supports 3 – axis, 4 – axis (with a rotary table), and 5 – axis simultaneous machining, capable of handling complex curved surfaces, irregular structures, and multi – angle processing requirements.

Accuracy Levels:

Regular Accuracy: ±0.01mm (suitable for automotive parts, industrial molds, etc.);

High Accuracy: ±0.005mm (miniature medical parts, precision instrument components, etc.).

Surface Roughness: Ra0.2 – 0.63μm (can be optimized to Ra0.01μm).

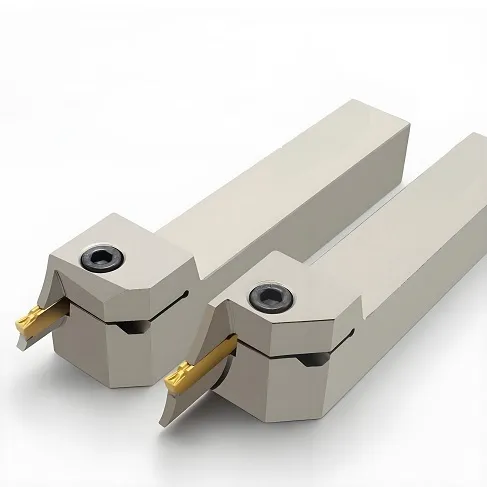

Processing Methods

Covers milling, turning, drilling, wire – cutting, laser processing, and rapid prototyping technologies. Also supports turn – milling compound processing (integrated forming of complex parts).

Metal Materials

Regular Materials: Aluminum alloys (6061 – T6, 7075 – T), stainless steels (304/316L/17 – 4), titanium alloys (TC4/TA1), copper – based alloys (brass, bronze).

Special Materials: Carbon steels (4140/Q235), hardened metals, PEEK – based alloys (high – temperature – resistant/corrosion – resistant).

Surface Treatments

Basic Processes: Anodizing (black/silver/color), electroplating (chrome – plating/nickel – plating), sand – blasting/polishing.

Function Enhancement: PVD coating (wear – resistant), nitriding treatment (corrosion – resistant), anti – rust coating (suitable for marine environments).