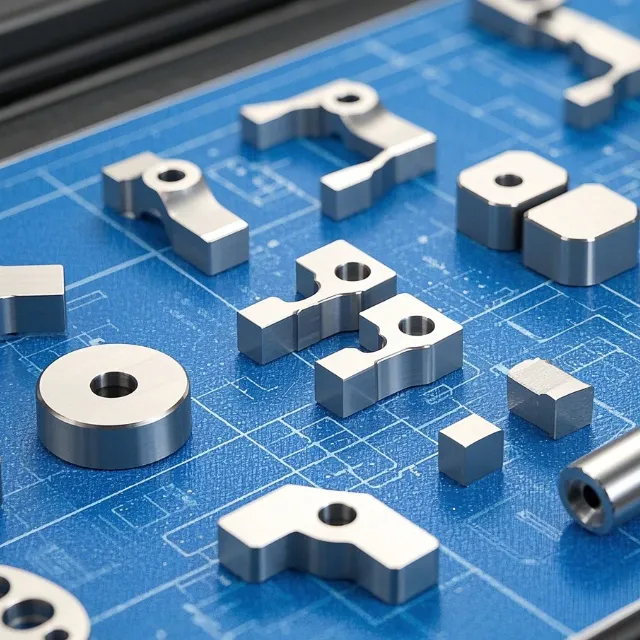

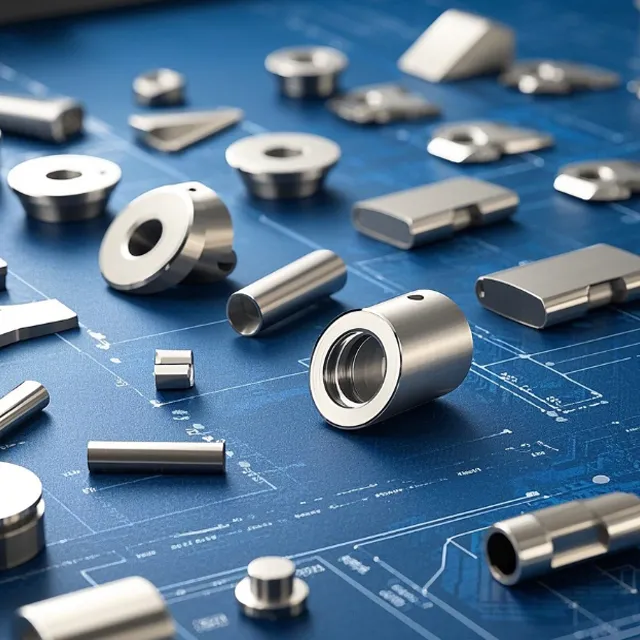

Custom CNC Serving Turning Metal Machining Service

Place of Origin : Fujian, China

Type : Milling, Turning

Micro Machining or Not : Micro Machining

Model Number : CMP-439

Brand Name : JSD

Product name : Custom CNC Machining Service

Material : Customers’ Requirement

Surface treatment : Painting\Powder Coating\Plating\Polishing

Process : Cnc Machining + Surface Treatment

Service : Customized OEM

Color : Customized Color

Size : Customer Size

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

OEM/ODM : OEM ODM CNC Milling Turning Machining Service

Tolerance : 0.01- +/-0.005mm

Description

Service Overview

We offer high – precision CNC lathe custom machining services, covering various metal processing techniques such as turning, milling, drilling, and boring. Our services are suitable for the precision part processing of a variety of materials, including aluminum alloy, stainless steel, titanium alloy, copper parts, carbon steel, and engineering plastics. With advanced CNC equipment and a technical team, we are committed to providing customers with high – precision, high – efficiency, and cost – effective custom machining solutions.

Core Service Content

CNC Turning

Capable of processing rotary parts such as shafts, discs, sleeves, and threaded parts.

Supports precision turning of outer circles, inner bores, end faces, tapered surfaces, threads, and grooving.

The machining accuracy can reach ±0.005mm, and the surface roughness is Ra1.6μm.

Milling (CNC Milling Machine / Machining Center)

Suitable for the processing of complex curved surfaces, special – shaped parts, and precision molds.

Supports 3 – axis / 4 – axis / 5 – axis machining.

The machining accuracy can reach ±0.01mm.

Composite Machining (Turn – Milling Integration)

Completes multiple processes such as turning, milling, drilling, and tapping in one clamping.

Reduces clamping errors and improves processing efficiency and accuracy.

Special Material Processing

Difficult – to – machine materials such as titanium alloy, superalloy, and cemented carbide.

Provides professional tooling solutions to ensure processing quality.

Service Advantages

✅ High – Precision Machining: We use imported CNC equipment (such as FANUC and SIEMENS systems) to ensure stable machining accuracy.

✅ Quick Response: The sample – making cycle is 1 – 3 days, and the mass – production cycle is 4 – 7 days, shortening the delivery time.

✅ Flexible Customization: Supports small – batch trial production to large – batch production, meeting different needs.

✅ Surface Treatment: Provides post – treatment services such as sandblasting, electroplating, anodizing, and polishing.

✅ Quality Assurance: Conducts full – process quality inspection (coordinate measuring, projector inspection, etc.) to ensure that products meet the requirements of the drawings.

Applicable Industries

🔹 Automotive parts (shafts, gears, flanges, bearing housings, etc.)

🔹 Aerospace (precision structural parts, engine parts, etc.)

🔹 Medical devices (surgical instruments, implants, dental parts, etc.)

🔹 Electronics and communication (5G base station parts, radiators, connectors, etc.)

🔹 Industrial automation (robot components, guide rails, lead screws, etc.)

Service Process

Requirement Communication: Customers provide drawings or samples and clarify technical requirements.

Process Evaluation: Engineers formulate processing plans and optimize costs and delivery times.

Quotation Confirmation: Provide a transparent quotation and sign a contract.

Production and Processing: CNC programming, precision machining, and quality inspection.

Delivery and Acceptance: Package and ship the products, and provide inspection reports.

📞 Contact Us: If you need custom services, feel free to consult. We will provide you with professional technical support and the best processing solutions!