Custom High-Precision CNC Parts

|

Attribute

|

Specification

|

|

Product Name

|

Custom High-Precision CNC Parts

|

|

Processing Technology

|

High-Precision CNC Machining

|

|

Machining Accuracy

|

±0.005mm

|

|

Surface Roughness

|

Ra 0.1μm

|

|

Material Type

|

Metals, Alloys, Engineering Plastics

|

|

Minimum Order Quantity

|

1 piece

|

|

Quality Certification

|

ISO 9001:2015

|

Description

Product Specification Sheet

Basic Information

|

Attribute

|

Specification

|

|

Product Name

|

Custom High-Precision CNC Parts

|

|

Processing Technology

|

High-Precision CNC Machining

|

|

Machining Accuracy

|

±0.005mm

|

|

Surface Roughness

|

Ra 0.1μm

|

|

Material Type

|

Metals, Alloys, Engineering Plastics

|

|

Minimum Order Quantity

|

1 piece

|

|

Quality Certification

|

ISO 9001:2015

|

Material Selection

|

Material Category

|

Specific Materials

|

Characteristics

|

Application Scenarios

|

|

Aluminum Alloys

|

6061, 7075, 5052

|

Lightweight, Corrosion Resistant, Easy to Machine

|

Aerospace, Automotive Parts

|

|

Stainless Steel

|

304, 316, 416

|

Corrosion Resistant, High Strength

|

Medical Devices, Food Equipment

|

|

Titanium Alloys

|

Ti-6Al-4V, Pure Titanium

|

High Strength, Biocompatible

|

Aerospace, Medical Implants

|

|

Alloy Steels

|

4140, 4340, H13

|

High Strength, Wear Resistant

|

Mold Making, Mechanical Parts

|

|

Engineering Plastics

|

PEEK, PEI, PPS

|

High Temperature Resistant, Insulating

|

Electronic Parts, Medical Devices

|

Manufacturing Capabilities

|

Process Type

|

Accuracy Range

|

Maximum Size

|

Surface Roughness

|

|

CNC Milling

|

±0.005mm

|

1000×600×500mm

|

Ra 0.1μm

|

|

CNC Turning

|

±0.002mm

|

Φ300×500mm

|

Ra 0.05μm

|

|

5-Axis Machining

|

±0.008mm

|

800×600×400mm

|

Ra 0.2μm

|

|

EDM Machining

|

±0.001mm

|

500×300×200mm

|

Ra 0.02μm

|

Mechanical Properties Comparison

|

Material

|

Density(g/cm³)

|

Tensile Strength(MPa)

|

Hardness(HRC)

|

Temperature Resistance(°C)

|

|

6061 Aluminum

|

2.70

|

310

|

95HB

|

82

|

|

7075 Aluminum

|

2.81

|

572

|

150HB

|

121

|

|

304 Stainless Steel

|

7.93

|

505

|

92HRB

|

870

|

|

Titanium Alloy Ti-6Al-4V

|

4.43

|

950

|

36HRC

|

400

|

|

PEEK

|

1.32

|

90

|

–

|

260

|

Product Description

Product Overview

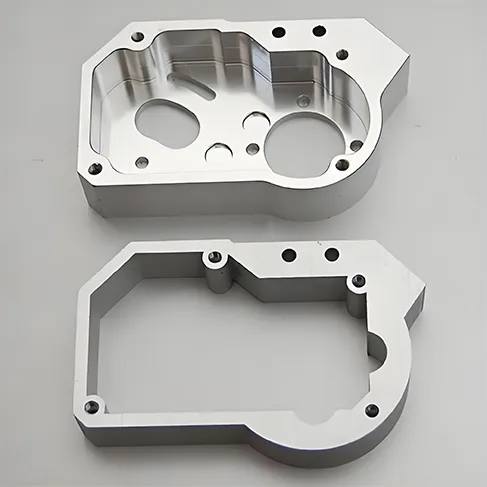

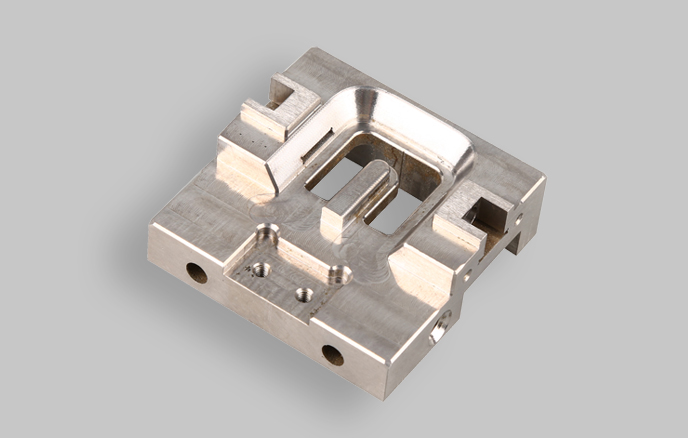

Custom High-Precision CNC Parts are high-precision mechanical components manufactured using advanced CNC machining technology. We specialize in providing one-stop precision machining solutions from prototyping to mass production for global customers. Our products are widely used in aerospace, automotive manufacturing, medical devices, electronic equipment and other high-end manufacturing fields.

Core Technical Advantages

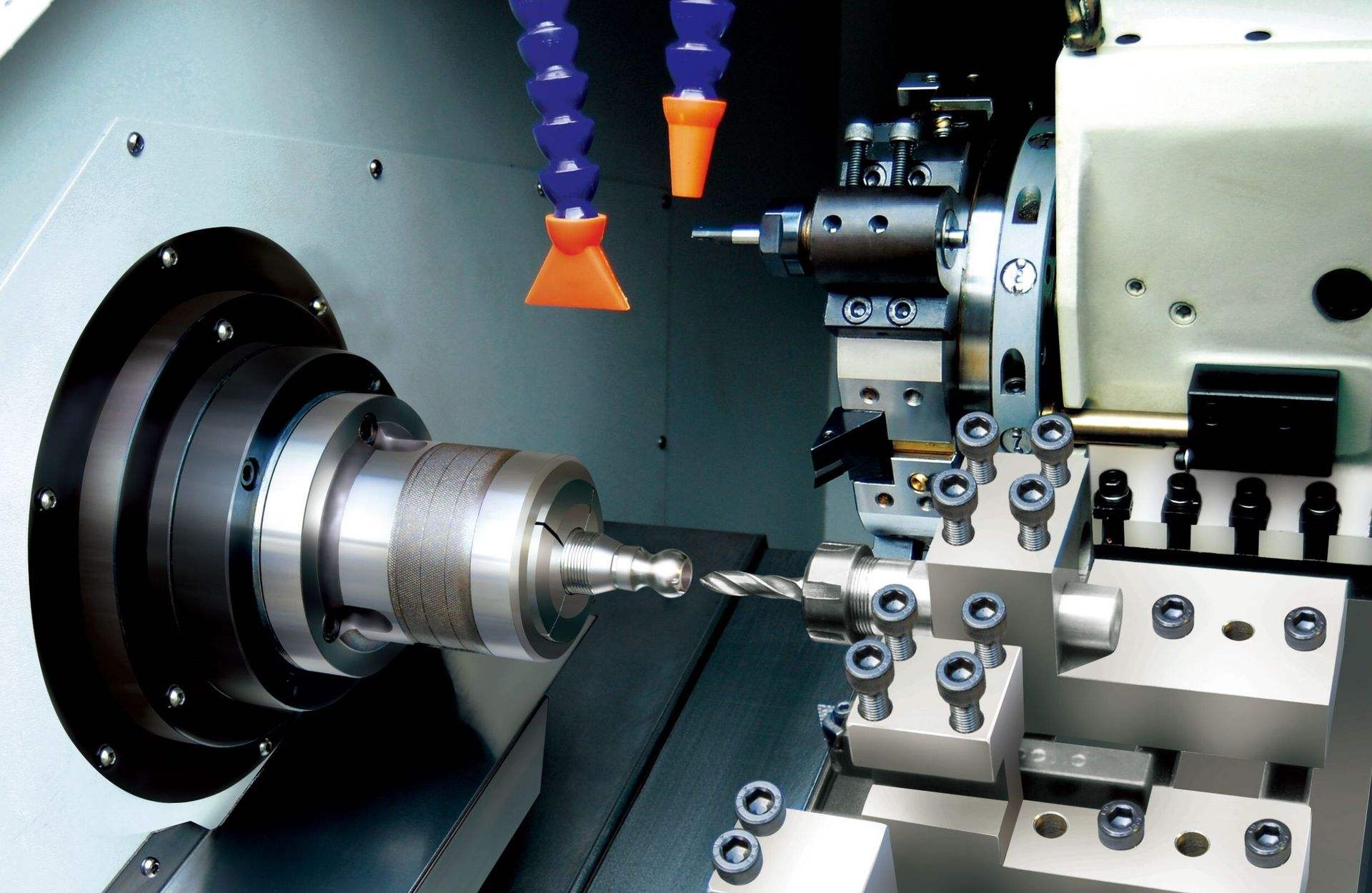

1. Ultra-High Precision Machining Capability

- Micron-level precision control: Machining accuracy up to ±0.005mm, meeting the most stringent precision requirements

- Advanced equipment configuration: Equipped with 5-axis CNC machining centers, high-precision lathes, EDM equipment, etc.

- Intelligent processing system: Adopting high-end CNC systems from FANUC, Siemens, ensuring processing stability

2. Diversified Material Processing

- Metal materials: Aluminum alloys, stainless steel, titanium alloys, alloy steels, etc.

- Engineering plastics: PEEK, PEI, PPS, nylon and other high-performance plastics

- Special materials: High-temperature alloys, composite materials, ceramics and other difficult-to-machine materials

3. Comprehensive Processing Services

- CNC Milling: 3-5 axis milling processing, complex 3D structure manufacturing

- CNC Turning: High-precision turning processing, cylindrical parts manufacturing

- EDM Machining: Electrical discharge machining, precision mold manufacturing

- Surface Treatment: Anodizing, electroplating, heat treatment, coating, etc.

Contact Us

Company Name: Xiamen Gold Cattle Machinery Co., Ltd.

Email: charlie@plasticmetalparts.com

Website: www.xmgoldcattle.com

Service Hours: Monday to Friday 8:00-18:00

Emergency Contact: 24-hour technical support hotline

The information on this product page is for reference only. Specific product specifications and prices are subject to actual quotations. We reserve the right to final interpretation of product information.