Custom Plastic Gears | Precision Injection Molded | POM/PA/PEEK

|

Service Item

|

Details

|

Technical Parameters

|

Delivery Time

|

|

Gear Design

|

Custom gear geometry optimization

|

Module 0.1-5.0, Pressure angle 20°

|

Design: 3-5 daysPrototype: 7-10 days

|

|

Injection Molding

|

High-volume production

|

POM/PA/PEEK materialsISO 5-7 precision grade

|

Sample: 5-8 daysBulk: 15-20 days

|

|

CNC Machining

|

Low-volume precision gears

|

±0.005mm toleranceComplex geometries

|

Sample: 3-5 daysBulk: 10-15 days

|

|

Material Selection

|

Engineering polymers

|

POM, PA66+GF, PEEKSelf-lubricating grades

|

Based on material inventory

|

|

Quality Testing

|

Comprehensive inspection

|

CMM measurementNVH performance testing

|

Production synchronous

|

|

Surface Treatment

|

Special coatings

|

Lubrication enhancementWear resistance coating

|

2-3 days finishing

|

Description

Our Precision Gear Solutions

Explore our high-quality plastic gears designed for various industrial applications

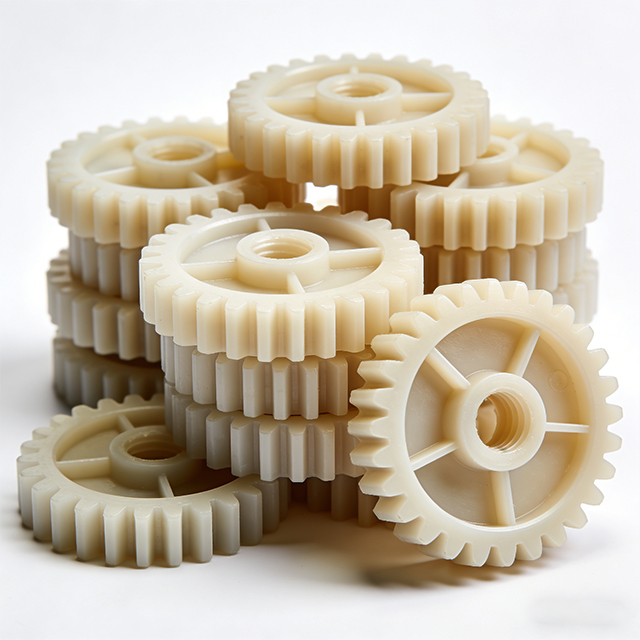

Precision Plastic Gears for Modern Engineering

Our custom precision plastic gears are engineered to deliver exceptional performance in the most demanding applications. With over 15 years of experience in injection molding and gear design, we specialize in creating high-precision polymer gears that outperform traditional metal components in weight, noise reduction, and maintenance requirements.

Using advanced CAD/CAM design tools and state-of-the-art injection molding equipment, we produce gears with ISO 5-7 precision levels and tolerances as tight as ±0.005mm. Our materials include POM, PA66+GF, PEEK, and other high-performance polymers that offer excellent wear resistance, chemical stability, and temperature resistance.

Whether you need miniature gears for medical devices, high-strength gears for automotive applications, or corrosion-resistant gears for industrial equipment, our engineering team will work with you to develop the optimal solution that meets your exact specifications and performance requirements.

Key Advantages

Why choose our precision plastic gears for your application

Lightweight Design

Up to 80% weight reduction compared to traditional metal gears, reducing overall system weight and energy consumption. This is particularly beneficial for automotive applications where every kilogram saved translates to improved fuel efficiency and reduced emissions.

Quiet Operation

50% noise reduction (3dB) for quieter operation, ideal for consumer electronics and medical devices. Our plastic gears operate with significantly less noise than metal gears, making them perfect for applications where noise reduction is critical.

Self-Lubricating

Eliminates the need for additional lubrication systems, reducing maintenance costs and complexity. Our self-lubricating materials maintain consistent performance over millions of cycles without the need for oil or grease.

High Precision

ISO 5-7 precision grade with tight tolerances down to ±0.005mm for reliable performance. Our advanced manufacturing processes ensure consistent quality and performance across all production runs.

Technical Specifications

Precision parameters and performance capabilities

Material Selection Guide

Choose the right polymer for your application requirements

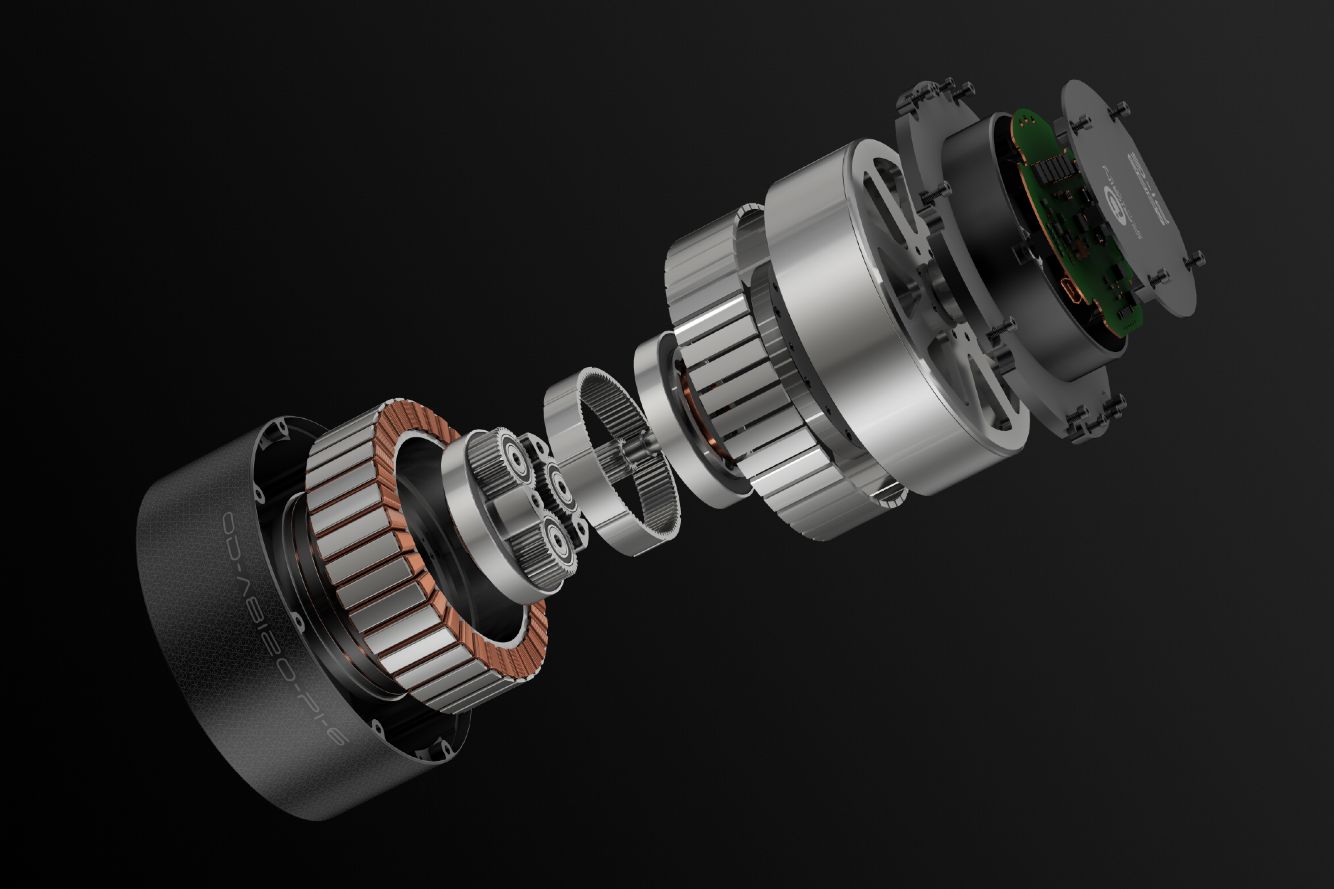

Advanced Manufacturing Process

Our state-of-the-art production capabilities ensure consistent quality and precision

Design & Engineering

Advanced CAD/CAM design with FEA analysis to optimize gear geometry for plastic materials. Our engineering team works closely with customers to develop custom solutions.

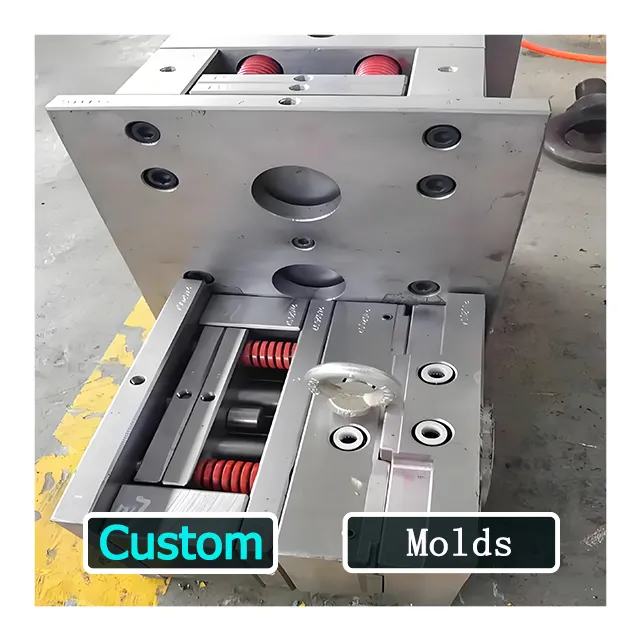

Mold Making

Precision mold making with hardened steel tooling for long production runs. Our molds are designed to minimize material shrinkage and ensure dimensional accuracy.

Injection Molding

High-precision injection molding with computer-controlled processes. We use advanced machines with closed-loop control for consistent part quality.

Quality Control

100% inspection using CMM and vision systems. Our quality control processes ensure every gear meets the specified precision requirements.

Quality Assurance

Our commitment to precision and reliability

Certified Quality Management

We maintain the highest standards of quality through our comprehensive quality management system:

- ✓

IATF 16949:2016 certification for automotive industry - ✓

PPAP Level 3 documentation capability - ✓

ISO 5 grade precision with CPK ≥1.67 - ✓

Advanced CMM measurement systems - ✓

100% inspection before shipment

Our quality control processes ensure that every gear meets or exceeds your specifications, providing consistent performance and reliability. We are committed to continuous improvement and invest heavily in training and technology to maintain our competitive edge.

Sustainable Solutions

Environmentally friendly alternatives to traditional metal gears that reduce your carbon footprint

Our plastic gears are manufactured using sustainable processes and materials that help you meet your environmental goals while maintaining high performance standards. By reducing weight and eliminating the need for lubrication, our solutions contribute to overall system efficiency and sustainability.

Frequently Asked Questions

Answers to common questions about our precision plastic gears

+

+

+

+

+