Description

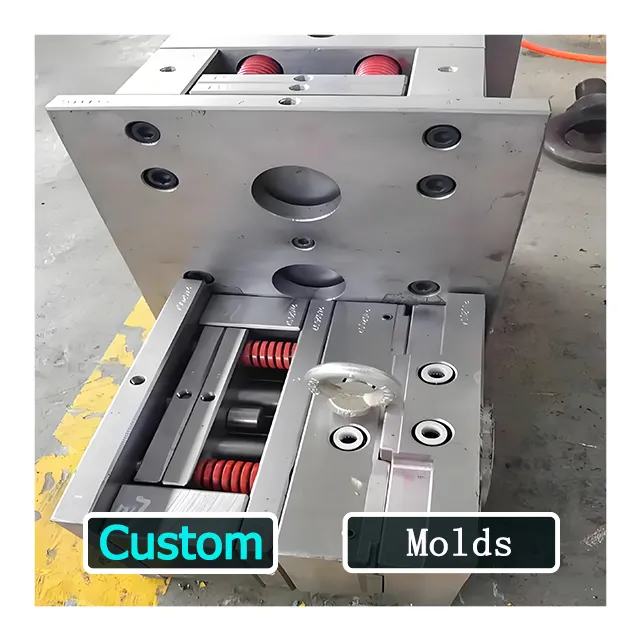

25 Years of Precision Manufacturing Expertise · Full Customization for Electronic Device Housings — One-Stop Solutions from Concept to Mass Production

As a high-tech enterprise with 25 years of experience in precision plastic processing, we provide end-to-end customization services for electronic device components such as instrument meter housings, battery cases, and switch power supply boxes. Equipped with 100+ injection molding machines (clamping force 50–1,000 tons), SMT patching production lines, and 3D measurement equipment, we control every 环节 from material R&D and mold design to finished product assembly, delivering high-quality customized solutions to 200+ global clients.

✅ Housing Customization:

- Instrument and meter housings (precision structures for various sensors)

- Battery cases (fire-retardant design, supporting multi-cell layouts)

- Switch power supply boxes (optimized heat dissipation, EMI shielding treatment)

✅ Circuit Board Services:

- PCB design (2–16 layers, minimum line width/spacing 3/3mil)

- SMT patching (01005 ultra-precision placement, CPK ≥1.67)

- Functional testing (ICT, FCT automated testing)

✅ Material Solutions:

- General engineering plastics (ABS/PC/PP)

- Special engineering plastics (LCP/PPS/PEEK)

- Medical-grade materials (compliant with FDA/ISO10993 standards)

🔧 Equipment Advantages:

- Japanese Sumitomo electric injection molding machines (precision ±0.01mm)

- German DMG 5-axis machining centers (precision machining for complex surfaces)

- Fully automated AOI optical inspection systems (PCB defect rate <0.01%)

💡 Technical Support:

- Free DFM (Design for Manufacturability) analysis

- Moldflow analysis to optimize gate locations

- Finite element analysis (FEA) for structural strength evaluation

🌍 Global Services:

- Samples delivered via DHL/UPS (3–5 days)

- Bulk orders FOB Shenzhen/Guangzhou, EXW/DDP terms supported

- 7×24-hour technical support for rapid customer response

-

Submit Requirements:

- Upload 3D models (STP/IGS format) or describe product functional requirements

- Specify application scenarios (indoor/outdoor/medical/industrial)

-

Solution Evaluation:

- Material selection and structural optimization suggestions within 48 hours

- Detailed quotation and project schedule issued within 72 hours

-

Sample Confirmation:

- Sample production completed in 7–15 days (3D printing/injection molding)

- Comprehensive inspection reports provided (dimensions/performance/reliability)

-

Bulk Production:

- First batch delivery within 20–45 days after mold approval

- Support mixed production (small batches of multiple models)