Custom Pvc Abs Plastic Hardware Acrylic Parts

Description

Our Plastic Parts – Built for Perfection

Why Choose Our Plastic Parts? Because Quality Matters

Dude, these aren’t your average plastic parts! We use only the highest grade PVC, ABS, and acrylic materials that meet international standards.

Perfect for:

- Industrial Equipment: Precision components that work flawlessly

- Electronics: Sleek enclosures that protect your gear

- Medical Devices: Clean, durable parts you can trust

- Consumer Products: Beautiful finishes that impress customers

Fun fact: Our acrylic parts have 92% light transmission – that’s almost as clear as glass!

Materials – We Use The Good Stuff

PVC – The Tough One

Bro, PVC is like the bodybuilder of plastics! This stuff is super strong and resistant to just about everything.

Key Properties:

- Tensile Strength: 7,450 psi (ASTM D638)

- Compressive Strength: 9,600 psi (ASTM D95)

- Flexural Strength: 14,450 psi (ASTM D790)

- Specific Gravity: 1.40 g/cm³

- Water Absorption: 0.04-0.40% (24 hours)

Perfect for: Pipes, fittings, electrical components, construction parts

ABS – The Versatile One

Dude, ABS is like the Swiss Army knife of plastics! It’s strong, flexible, and can be molded into just about any shape.

Key Properties:

- Impact Resistance: Excellent (even at low temps)

- Tensile Strength: 4,000-7,000 psi

- Heat Deflection Temp: 176-212°F

- Chemical Resistance: Good against oils and chemicals

- Surface Finish: Smooth, paintable

Perfect for: Toys, electronics, automotive parts, household items

Acrylic – The Clear One

Bro, acrylic is like glass but better! It’s crystal clear, 17x stronger than glass, and won’t shatter.

Key Properties:

- Light Transmission: 92% (vs glass 89%)

- Tensile Strength: 10,000 psi (ASTM D638)

- Compressive Strength: 18,000 psi (ASTM D695)

- Rockwell Hardness: M-94

- UV Resistance: Excellent (won’t yellow)

Perfect for: Displays, signs, lenses, protective barriers

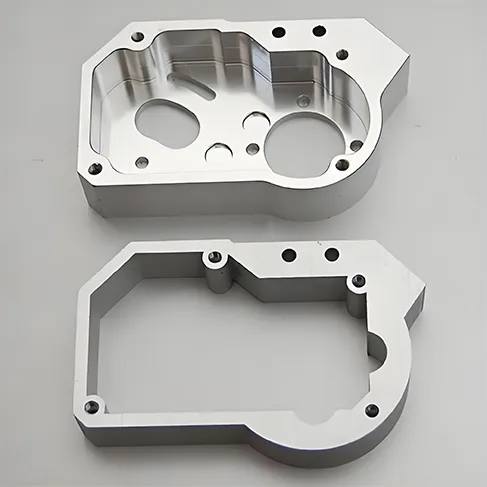

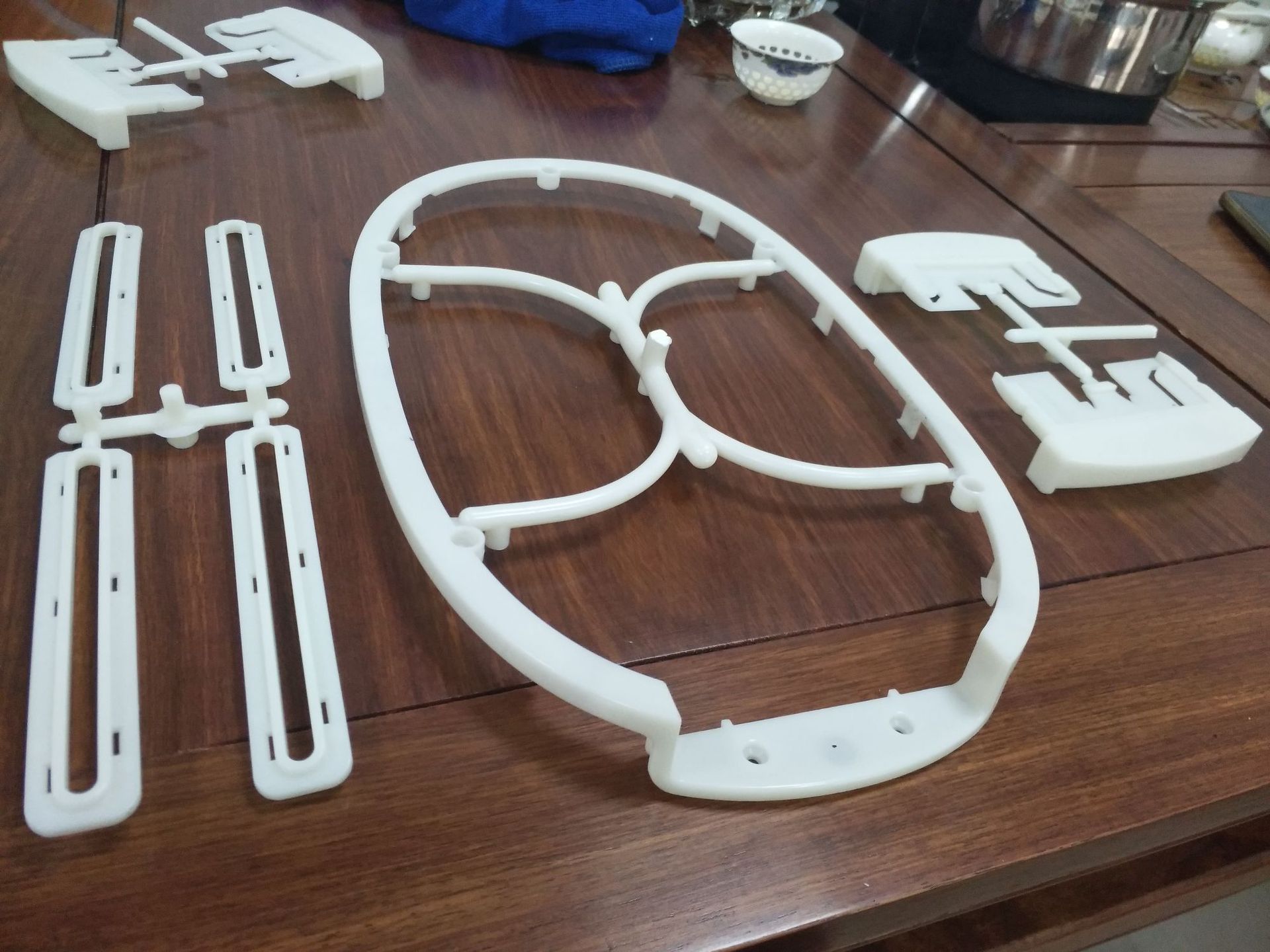

Our Manufacturing Process – We Don’t Cut Corners

Design & Prototyping

CAD design + 3D printing

Mold Making

Precision CNC machining

Material Preparation

Drying + color mixing

Injection Molding

High-pressure injection

Finishing

Trimming + polishing

Pro Tip From The Pros

Bro, the injection molding step is where the magic happens! We use temperatures up to 220°C and pressures up to 2000 bar to make sure every part is perfect. And we check every single piece with our quality control team – no defects get past us!

Standards & Certifications – We Play By The Rules

Industry Standards We Follow

- ISO 15493: Thermoplastics piping systems (ABS, PVC-U, PVC-C)

- ASTM D638: Tensile properties of plastics

- ASTM D790: Flexural properties of plastics

- ASTM D695: Compressive properties of rigid plastics

- ISO 2507: Vicat softening temperature test

- GB/T 8814-2020: Chinese standard for PVC profiles

Pro tip: Always check if your plastic parts meet the right standards – quality matters, am I right?

Our Certifications

These aren’t just fancy certificates – they’re proof that our products meet the highest international standards.

Every batch of plastic parts undergoes rigorous testing to ensure compliance with all relevant standards.

Test Data – The Proof Is In The Numbers

DISCLAIMER: All test data below is for reference only. Actual results may vary based on specific application conditions.

Mechanical Properties Comparison

| Property | PVC | ABS | Acrylic |

|---|---|---|---|

| Tensile Strength (psi) | 7,450 | 5,500 | 10,000 |

| Compressive Strength (psi) | 9,600 | 12,000 | 18,000 |

| Flexural Strength (psi) | 14,450 | 9,000 | 16,000 |

| Specific Gravity | 1.40 | 1.05 | 1.19 |

Environmental Resistance Test

| Test Condition | Result | Duration |

|---|---|---|

| Water Immersion | No degradation | 1000 hours |

| UV Exposure | Minimal yellowing | 500 hours |

| Temperature Cycling | No cracking | -40°C to 80°C |

| Chemical Resistance | Excellent | Oils, solvents |

Quality You Can Trust

- Dimensional Tolerance: ±0.05mm (critical dimensions)

- Surface Roughness: Ra 0.8μm (standard finish)

- Color Consistency: ΔE ≤ 1.0 (color matching)

- Impact Resistance: IK08 rating (mechanical protection)

- Flammability: UL94 V-0 (fire safety)

Key Features – Why Our Parts Are Better

Precision Machined

Tight tolerances ensure perfect fit in your products

Vibrant Colors

Custom color matching for any design requirement

High Strength

Durable construction that withstands daily use

Fast Production

Quick turnaround times for your urgent needs

Eco-Friendly

Recyclable materials with minimal environmental impact

Easy Assembly

Designed for simple integration into your products

Applications – We Do It All

Industrial Equipment

Machine guards, gears, housings

Electronics

Phone cases, computer parts, enclosures

Medical Devices

Instrument trays, handles, covers

Retail Displays

Shelves, sign holders, product stands

Automotive

Interior trim, knobs, bezels

Home & Office

Furniture parts, organizers, accessories

Why Choose Us? – Let Us Count The Ways

26 Years of Plastic Expertise

Bro, we’ve been making plastic parts since 1999! That’s not just experience – that’s mastery.

We’ve seen it all, solved it all, and we keep getting better.

Customization Experts

Need a specific shape, size, or color? We can make it happen. No design is too complex for us.

Our team works with you to create exactly what you need – no compromises.

Quality Guaranteed

Every product undergoes strict quality control. We don’t ship anything we wouldn’t use ourselves.

If you’re not happy, we’re not happy – it’s that simple.

Ready to create perfect plastic parts for your business?

Let’s Create Something Amazing

We’re here to help you with all your plastic part needs

Phone

+86-18150097490

charlie@plasticmetalparts.com

Location

Xiamen, China