Customized 5 Axis CNC Machining Service China

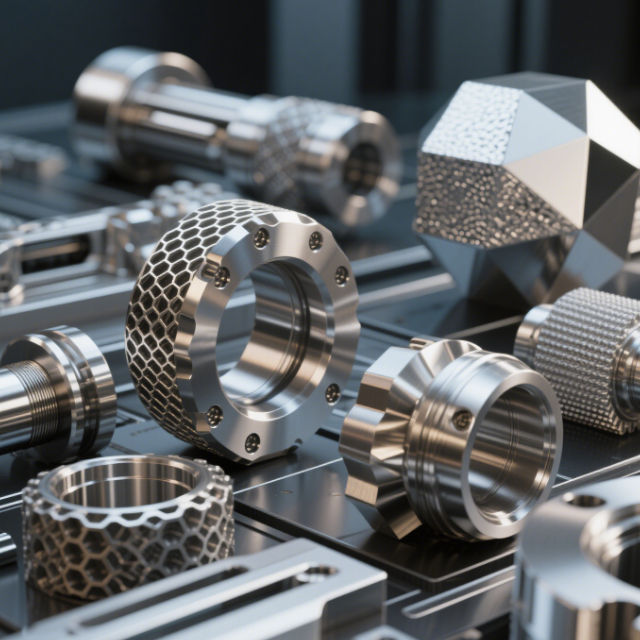

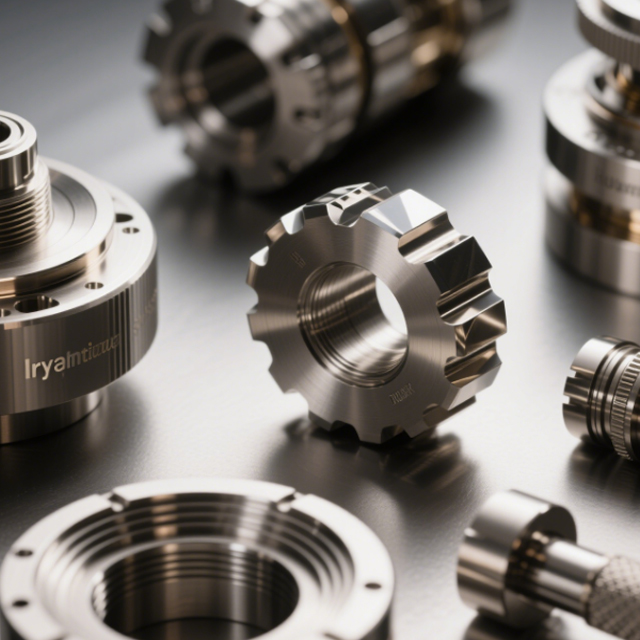

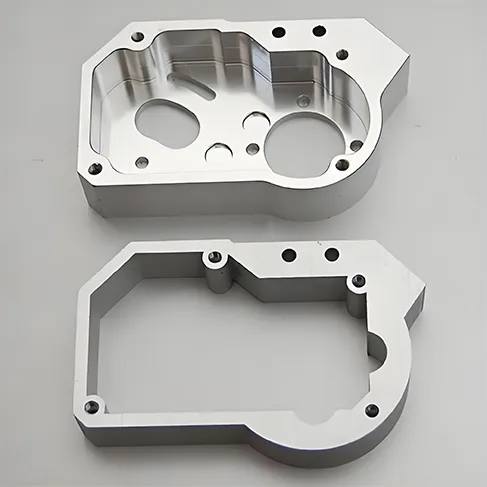

Processing Capabilities: Capable of processing complex curved surfaces and irregular structural parts. Five – sided machining can be completed in one clamping, improving processing efficiency and accuracy.

Processing Precision: The positioning accuracy is ±0.005 mm, meeting the processing requirements of high – precision components and ensuring product consistency.

Equipment Configuration: Equipped with internationally renowned brand five – axis CNC machining centers, enabling high – speed and efficient cutting.

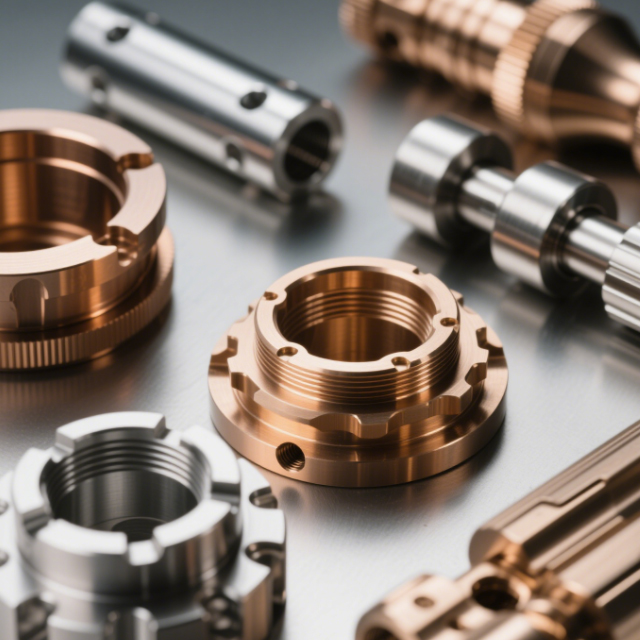

Applicable Materials: Compatible with a variety of metallic and non – metallic materials such as aluminum alloy, stainless steel, titanium alloy, and engineering plastics, meeting the application needs of different industries.

Surface Treatment: A variety of surface treatment processes such as anodizing, electroplating, sandblasting, and polishing are provided to enhance the appearance and performance of products.

Categories: CNC Machining Parts, Machining

Tag: CNC

Description

🌟 A Glimpse of Core Advantages

✔ Five – axis Precision Machining: Ultra – high precision of ±0.005mm, enabling complex curved surfaces and irregular structures to be formed in one go!

✔ Full Material Compatibility: Aluminum alloy, titanium alloy, stainless steel, engineering plastics, composite materials… Covering over 300 industrial – grade materials.

✔ Rapid Response and Delivery: Samples available within 72 hours, mass production in 7 – 15 days, and rush orders are supported.

✔ Zero – threshold Customization Service: Minimum order quantity of 1 piece. No fear of small – batch trial production, facilitating seamless transition from R & D to mass production.

✔ Full – process Digital Control: From drawing analysis → process optimization → intelligent machining → full – inspection delivery, the whole process is transparent and traceable.

✔ Five – axis Precision Machining: Ultra – high precision of ±0.005mm, enabling complex curved surfaces and irregular structures to be formed in one go!

✔ Full Material Compatibility: Aluminum alloy, titanium alloy, stainless steel, engineering plastics, composite materials… Covering over 300 industrial – grade materials.

✔ Rapid Response and Delivery: Samples available within 72 hours, mass production in 7 – 15 days, and rush orders are supported.

✔ Zero – threshold Customization Service: Minimum order quantity of 1 piece. No fear of small – batch trial production, facilitating seamless transition from R & D to mass production.

✔ Full – process Digital Control: From drawing analysis → process optimization → intelligent machining → full – inspection delivery, the whole process is transparent and traceable.

🔧 Why Choose Our Five – axis CNC Machining?

1️⃣ Technological Strength Empowering High – end Manufacturing

- Imported Five – axis Machine Tools: Equipment from international brands like DMG MORI and HAAS, ensuring both precision and stability.

- Team of Process Experts: With over 26 years of experience in aerospace and automotive fields, capable of solving industry challenges such as deep – cavity machining and thin – walled part deformation.

- Intelligent Simulation and Verification: Pre – machining simulation system to avoid interference risks and save 30% of trial – and – error costs.

2️⃣ Full Industry Coverage, Precisely Meeting Requirements

▸ Automotive Industry: Turbine blades, engine blocks, mold inserts

▸ Medical Devices: Orthopedic implants, precision endoscopic components

▸ Aerospace: Light – weight structural parts, core components of unmanned aerial vehicles

▸ Electronic Communication: 5G base station radiators, semiconductor fixtures

▸ Scientific Research Prototypes: High – precision experimental devices, customized scientific research parts

▸ Automotive Industry: Turbine blades, engine blocks, mold inserts

▸ Medical Devices: Orthopedic implants, precision endoscopic components

▸ Aerospace: Light – weight structural parts, core components of unmanned aerial vehicles

▸ Electronic Communication: 5G base station radiators, semiconductor fixtures

▸ Scientific Research Prototypes: High – precision experimental devices, customized scientific research parts

3️⃣ Double Commitment to Quality and Service

✅ Strict Quality Inspection System: Complete inspection using CMM (Coordinate Measuring Machine) and roughness tester, accompanied by ISO 9001 – certified inspection reports.

✅ Worry – free After – sales Service: Free rework for quality issues, with 1 – to – 1 follow – up by technical consultants throughout the process.

✅ Flexible Cooperation Modes: Support for confidentiality agreements on drawings, joint mold development, and long – term strategic cooperation.

✅ Strict Quality Inspection System: Complete inspection using CMM (Coordinate Measuring Machine) and roughness tester, accompanied by ISO 9001 – certified inspection reports.

✅ Worry – free After – sales Service: Free rework for quality issues, with 1 – to – 1 follow – up by technical consultants throughout the process.

✅ Flexible Cooperation Modes: Support for confidentiality agreements on drawings, joint mold development, and long – term strategic cooperation.

📊 Transparent Service Process

1️⃣ Demand Communication: Submit drawings/3D models online (in formats such as STEP/IGES/STL) → 2️⃣ Process Evaluation: Quote and delivery time feedback within 24 hours → 3️⃣ Intelligent Production: Real – time progress tracking → 4️⃣ Quality Acceptance: High – definition machining videos + inspection reports → 5️⃣ Express Delivery: SF Express/Deppon/DHL for global direct delivery.

1️⃣ Demand Communication: Submit drawings/3D models online (in formats such as STEP/IGES/STL) → 2️⃣ Process Evaluation: Quote and delivery time feedback within 24 hours → 3️⃣ Intelligent Production: Real – time progress tracking → 4️⃣ Quality Acceptance: High – definition machining videos + inspection reports → 5️⃣ Express Delivery: SF Express/Deppon/DHL for global direct delivery.

❓ Frequently Asked Questions

Q: What is the minimum order quantity (MOQ)?

A: We support orders starting from 1 piece, and can undertake both small – batch trial production and large – scale mass production.

Q: What is the minimum order quantity (MOQ)?

A: We support orders starting from 1 piece, and can undertake both small – batch trial production and large – scale mass production.

Q: Can you process high – hardness materials (such as quenched steel)?

A: Equipped with carbide cutting tools and liquid nitrogen cooling systems, we can process super – hard materials with HRC60+.

A: Equipped with carbide cutting tools and liquid nitrogen cooling systems, we can process super – hard materials with HRC60+.

Q: How to ensure the security of drawings?

A: Sign an NDA (Non – Disclosure Agreement), encrypt file transfer, and completely destroy the original files after processing.

A: Sign an NDA (Non – Disclosure Agreement), encrypt file transfer, and completely destroy the original files after processing.

Q: Do you provide surface treatment services?

A: We support over 20 post – treatment processes such as anodizing, electroplating, sandblasting, and laser engraving, which can be completed in one – stop.

A: We support over 20 post – treatment processes such as anodizing, electroplating, sandblasting, and laser engraving, which can be completed in one – stop.

🛠️ Act Now and Start High – efficiency Intelligent Manufacturing

Click “Online Inquiry” 👉 Upload drawings/3D models 👉 Obtain customized solutions 👉 Secure production capacity slots!

Click “Online Inquiry” 👉 Upload drawings/3D models 👉 Obtain customized solutions 👉 Secure production capacity slots!

📞 24 – hour Technical Hotline: 05922132965

📧 Business Cooperation: charlie@plasticmetalparts.com

📧 Business Cooperation: charlie@plasticmetalparts.com

✨ From concept to finished product, we make complex manufacturing simpler!

——With millimeter – level dedication, defining the infinite possibilities of precision manufacturing.

——With millimeter – level dedication, defining the infinite possibilities of precision manufacturing.