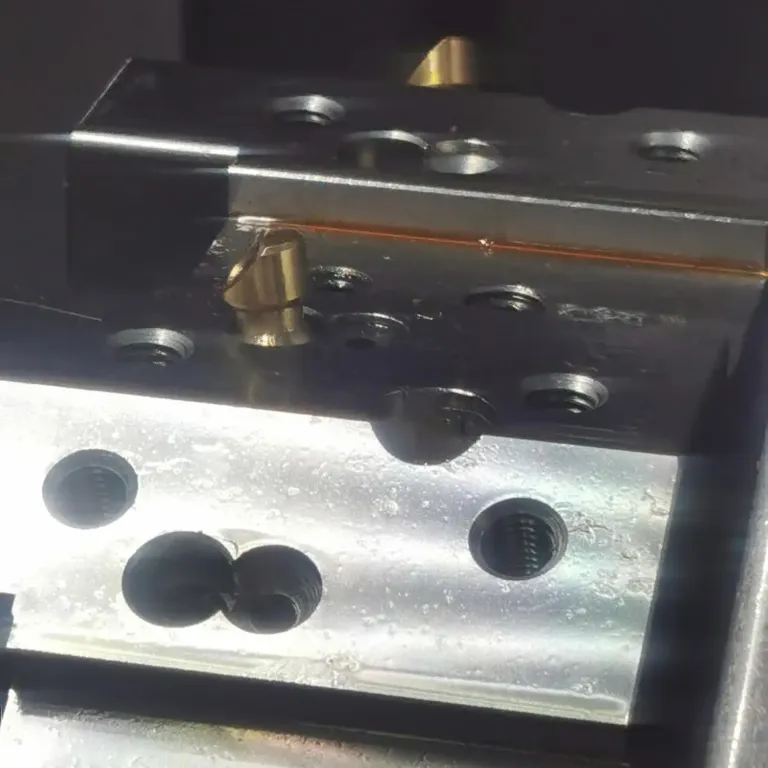

Customized Brass Ball Coolant Nozzles

Place of Origin : Fujian, China

Type : DRILLING, Milling, Turning

Micro Machining or Not : Micro Machining

Model Number : CMP-A7

Brand Name : JSD

Product name : Customized Brass Ball Coolant Nozzles

Material : Customers’ Requirement

Surface treatment : Customer’s Request

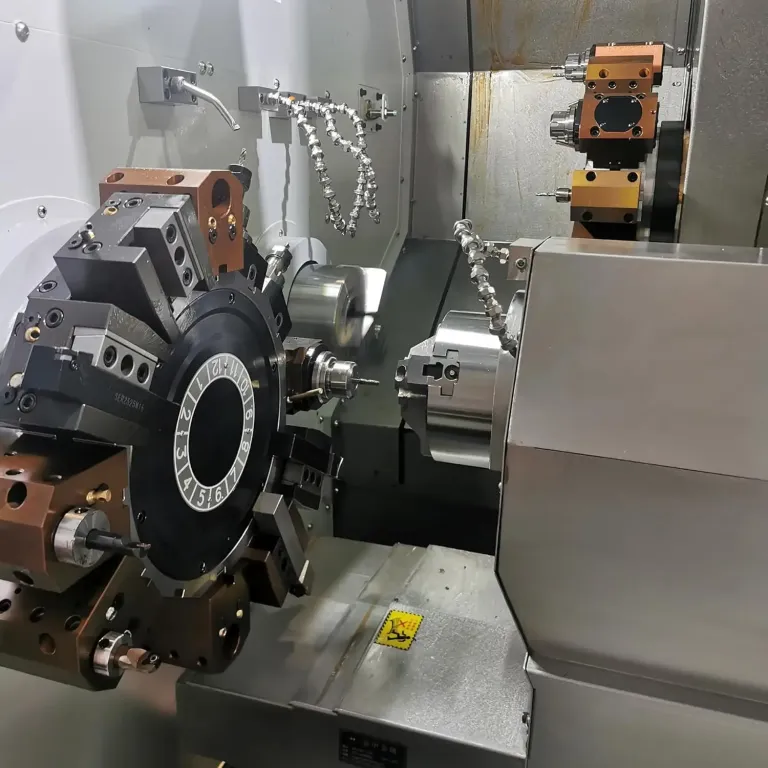

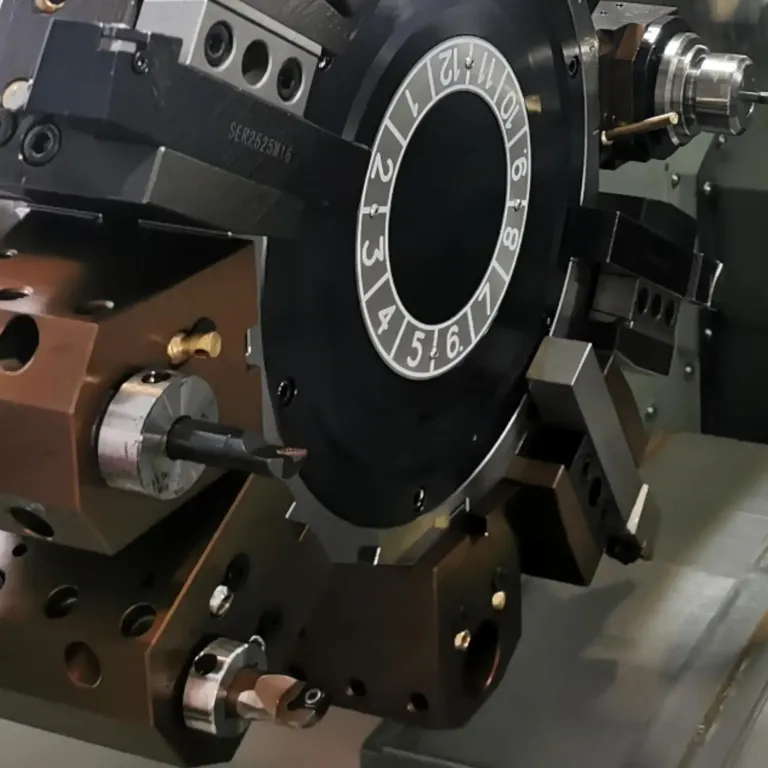

Equipment : 3/4/5 Axis CNC Machining Center

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Process : Cnc Machining + Surface Treatment

Service : Customized OEM

Tolerance : 0.01- +/-0.005mm

Certification : ISO9001

OEM/ODM : OEM ODM Non-standard Processing

Description

1. Products

Welcome to explore our customized brass spherical coolant nozzle! This nozzle is designed for industrial users and DIY enthusiasts who are looking for high-precision cooling effect. Made of high-quality brass material, combined with exquisite craftsmanship, it ensures that every spray is precise and accurate, meeting your high standard of coolant dispensing needs. Whether for machining, automotive maintenance or other applications requiring efficient cooling, this nozzle is the ideal choice for you.

2. Product Specifications

Material: High quality brass (H62)

Shape: Spherical

Nozzle diameter: 2mm for standard model (can be customized upon request)

Flow rate range: 5-20L/min (specific flow rate depends on system pressure and nozzle diameter)

Connection: G1/4” threaded port (can be customized upon request)

Surface treatment: polished, showing the natural luster of brass

Note: Due to the special nature of customized products, please confirm the exact specifications and details with customer service before placing an order to ensure that your needs are met.

3. Product Material

Brass (H62): excellent corrosion resistance and mechanical properties, suitable for use in a variety of harsh environments. Brass has good thermal conductivity, which helps the efficient transfer of coolant.

High-pressure resistant design: the internal structure of the nozzle is well-designed to withstand high system pressure and ensure long-term stable operation.

4. Product Craftsmanship

Precision casting: High-precision casting process is adopted to ensure that the shape and size of the nozzle are accurate.

Fine grinding: The surface of the nozzle is carefully ground and polished to remove the defects in the casting process and enhance the aesthetics and durability.

Strict testing: Each nozzle is subjected to strict flow and pressure tests before delivery to ensure stable and reliable performance.

5. Product use

Machining: used in CNC machine tools, machining centers and other equipment for coolant spraying, to improve processing efficiency and workpiece quality.

Automobile maintenance: used for cleaning and cooling engine parts in the process of automobile repair and maintenance.

Other applications: for various industrial scenarios that require precise control of coolant injection, such as cooling towers and heat exchangers.

6. Product customization

In order to meet the special needs of different customers, we provide comprehensive customization services:

Nozzle diameter: nozzle diameter can be customized according to your specific needs to achieve more precise coolant distribution.

Connections: A variety of connection options are available, such as G1/4”, NPT, BSP, etc., to suit different equipment and systems.

Special materials: In addition to brass, we also provide stainless steel, titanium alloy and other material choices to meet the needs of use in special environments.

Surface treatment: We provide a variety of surface treatment options such as polishing, plating, spraying, etc. to meet your different requirements for aesthetics and durability.

Customization process: Please contact customer service with your specific needs and equipment information. Our professional team will develop a detailed customization plan according to your needs and provide a quotation and delivery time.

Product Frequently Asked Questions

Q1: How is the corrosion resistance of this nozzle?

A: It is made of high quality brass material with good corrosion resistance, suitable for use in many harsh environments.

Q2: Can the flow rate of the nozzle be adjusted?

A: The flow rate of the nozzle is mainly determined by its diameter and system pressure. We can customize nozzles with different diameters to meet your flow requirements.

Q3: How to make sure the nozzle’s spraying direction is accurate?

A: Our nozzles are made by precision casting process to ensure accurate shape and size. Meanwhile, you can adjust the installation angle and position of the nozzle according to the actual need to realize the best spraying effect.

Q4: How long does it take to deliver customized products?

A: The delivery time of customized products mainly depends on your specific needs and the production arrangement of the factory. Generally speaking, we will complete the production and shipment within 7-15 working days after receiving your order and deposit. If you have any special needs or emergency, please contact our customer service and we will try our best to provide you with priority service.

Act now to customize an exclusive coolant nozzle for your equipment! We look forward to working with you to improve your productivity and work quality. If you have any questions or needs, please feel free to contact our customer service team, we will be happy to serve you.