Customized CNC machining manufacturing 10x10x0.8 6061 Aluminum jig plate fixture

Place of Origin : Fujian, China

Type : Other Machining Services

Micro Machining or Not : Micro Machining

Model Number : CMP-A14

Brand Name : JSD

Product name : Aluminum Fixture Plate Fixture

Material : Aluminum Alloy

Process : Cnc Machining + Surface Treatment

Surface treatment : Painting\Powder Coating\Plating\Polishing

Service : Customized OEM

Equipment : 3/4/5 Axis CNC Machining Center

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

OEM/ODM : OEM ODM Non-standard Processing

Certification : ISO9001

Tolerance : 0.01- +/-0.005mm

Description

1.Product Highlights

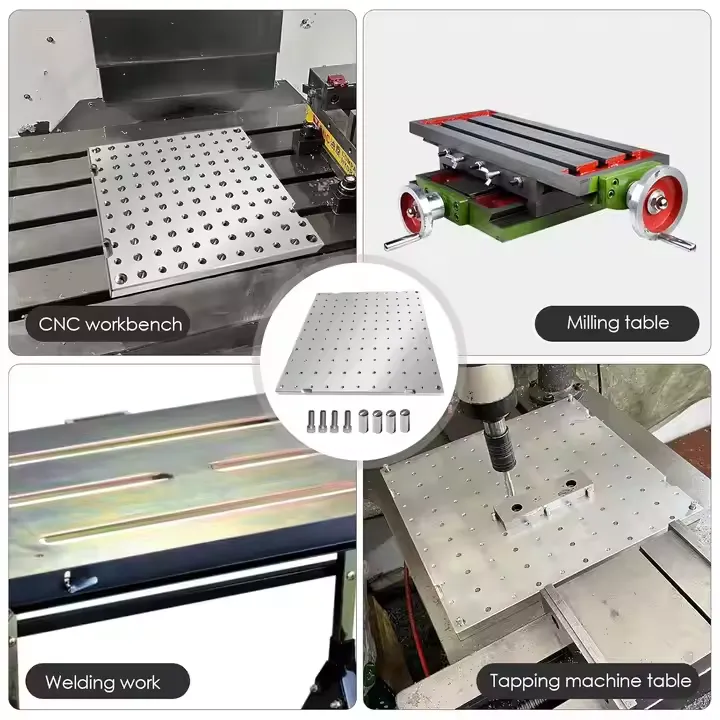

Precise customization: Based on your unique needs, we create aluminum fixture plate fixtures that perfectly fit your process. Whether it is shape, size or special functional requirements, we can accurately realize them to help your production operations efficiently and accurately.

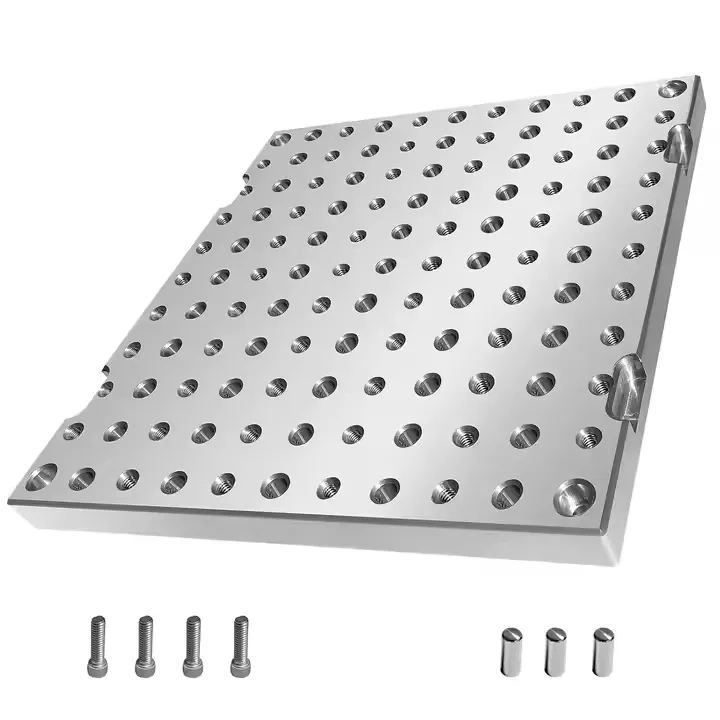

High-quality aluminum: We use high-quality aluminum alloy, which has excellent strength and hardness, and at the same time, it is lightweight and has good corrosion resistance, which effectively extends the service life of the fixture and ensures that it always maintains stable performance in the long-term use of the process.

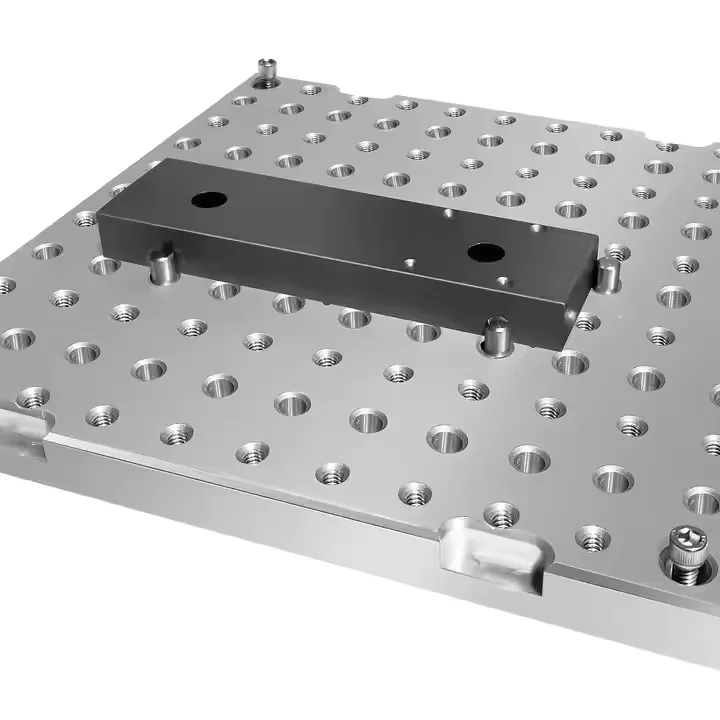

Exquisite craftsmanship: Advanced machining technology combined with high-precision CNC equipment to ensure the machining accuracy of each fixture. The surface is finely treated with high finish, effectively reducing friction and errors during processing, providing more stable clamping effect for your workpiece.

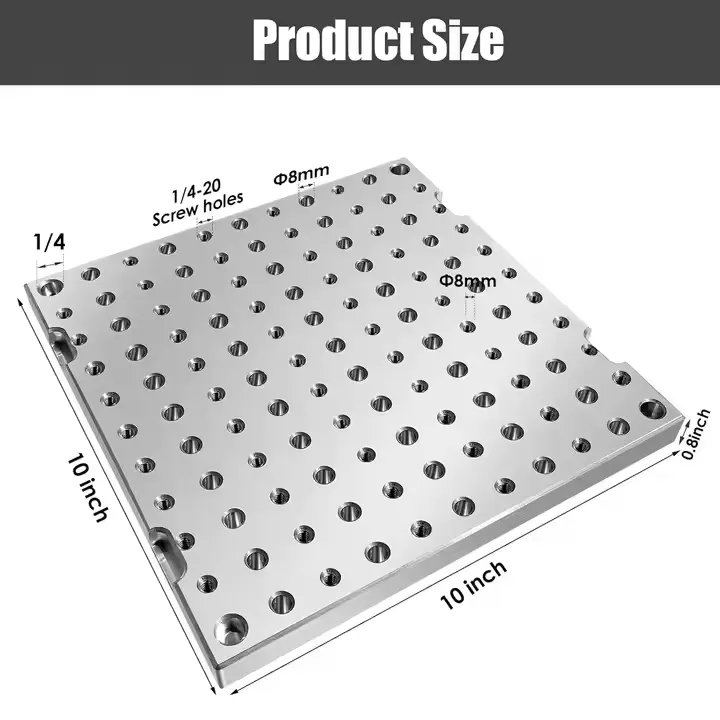

2.Specification

Material: aluminum alloy 6061/7075

Size range: length 100mm – 1000mm, width 50mm – 500mm, thickness 10mm – 100mm (can be customized special size)

Accuracy: ±0.01mm – ±0.05mm (customized according to specific requirements)

Surface treatment: anodized (color optional), hard oxidized, sandblasted, etc.

Installation holes: can be customized according to customer requirements of all kinds of standard or non-standard holes, hole tolerance ±0.02mm

Hardness: HB90 – HB150 (6061 aluminum alloy), HB150 – HB250 (7075 aluminum alloy).

3.Customization process

Consultation and communication: You can contact us through online customer service, phone or email to inform us of your preliminary needs for aluminum fixture plate fixtures, such as usage, approximate size, precision requirements, etc.

Demand Confirmation: Our professional team will receive your demand, and your in-depth communication, to further determine the detailed specifications of the fixture, material, surface treatment and other special requirements, and provide you with customized solutions and quotations.

Order production: After you confirm the customization plan and quotation, sign the contract and pay the deposit, we will start the production process immediately. During the production process, you can know the progress of your order at any time.

Quality Inspection: After completing the production, we will conduct a comprehensive inspection of the fixture according to strict quality inspection standards to ensure that the quality of the product meets your customized requirements.

Delivery logistics: after passing the quality inspection, we will arrange the shipment in time, provide you with the logistics single number to ensure that you can receive the customized aluminum jig plate fixture smoothly and provide perfect after-sales service.

Choose us to customize aluminum jig plate fixture, is to choose professional, accurate and efficient, let us work together to create exclusive your quality fixture solutions, to add strong power to your manufacturing.