Customized stainless steel valve accessories for chemical industry

Place of Origin: Fujian, China

Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Micro Machining or Not: Micro Machining

Model Number: CMP-01

Brand Name: JSD

Material: Aluminum

Process: Cnc Turning

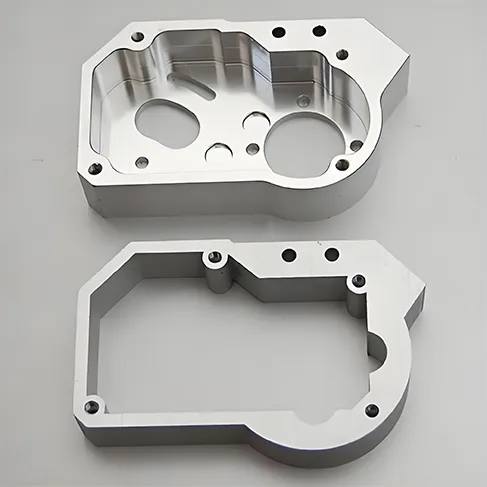

Product name: Aluminum Parts

Name: Customized Machined CNC Machining

Application: Automobile, Communication, Mechanical Equipment, Aircraft

Service: OEM ODM Customised

Keyword: CNC Macining Parts

Item Name: OEM Precision CNC Machining

Equipment: CNC Machining Centres

Packaging Details: Carton, wooden box, or depend on customer requested

Description

Our High Temperature Accessories – Built for the Hottest Environments

Why Our Stainless Steel? Because Regular Steel Can’t Handle This Heat

Dude, these accessories are engineered to withstand temperatures that would turn regular steel into a puddle! We’re talking up to 1100°C – that’s hotter than some lava!

Perfect for:

- Aerospace Industry: Jet engines? No problem, bro

- Automotive: Exhaust systems that can take the heat

- Industrial Machinery: Furnace components that last

- Chemical Processing: Corrosive environments? We got you

Fun fact: Our high-temperature alloy has a melting point of 1450°C – these parts aren’t going anywhere!

Materials – We Use the Good Stuff

High-Temperature Alloy Composition – The Secret Sauce

Bro, this isn’t your average stainless steel. Our high-temperature alloy is a specially formulated blend that combines:

Chromium (Cr)

18-22%

Nickel (Ni)

8-12%

Molybdenum (Mo)

2-3%

Carbon (C)

≤0.08%

Pro tip: The high chromium content creates a protective oxide layer that prevents corrosion even at extreme temperatures!

Key Properties – These Numbers Don’t Lie

| Property | Value | Unit |

|---|---|---|

| Max Operating Temp | 1100 | °C |

| Melting Point | 1450 | °C |

| Tensile Strength | ≥520 | MPa |

| Yield Strength | ≥205 | MPa |

| Elongation | ≥40 | % |

Compare that to regular steel – it starts losing strength at 300°C!

Our Manufacturing Process – We Don’t Cut Corners

Raw Material Selection

Only premium grade alloys

Melting & Refining

Vacuum induction melting

Hot Forming

Forging at 1150-1200°C

Heat Treatment

Solution annealing at 1050°C

Precision Machining

CNC machining to exact specs

Pro Tip From The Pros

Bro, the heat treatment step is crucial! We heat these parts to 1050°C and then quench them in water to create that perfect grain structure – that’s what gives them their amazing high-temperature strength!

Standards & Certifications – We Play By The Rules

Industry Standards We Follow

- ASTM A240: Standard for stainless steel plates, sheets

- ASTM A479: Standard for stainless steel bars for pressure vessels

- ASME SA-240: Boiler and pressure vessel code

- EN 10088-1: European standard for stainless steels

- GB/T 14976: Chinese standard for stainless steel pipes

- NACE MR0175: Sulfide stress cracking resistant materials

Pro tip: Always check if your high-temperature parts meet the right standards – safety first, am I right?

Our Certifications

These aren’t just fancy certificates – they’re proof that our products meet the highest international standards.

Every batch of our high-temperature accessories undergoes rigorous testing to ensure compliance with all relevant standards.

Test Data – The Proof Is In The Numbers

DISCLAIMER: All test data below is for reference only. Actual results may vary based on specific application conditions.

High Temperature Tensile Test Results

| Temperature | Tensile Strength | Yield Strength |

|---|---|---|

| 20°C (Room Temp) | 520 MPa | 205 MPa |

| 300°C | 480 MPa | 180 MPa |

| 600°C | 380 MPa | 140 MPa |

| 800°C | 280 MPa | 95 MPa |

| 1000°C | 150 MPa | 60 MPa |

Oxidation Resistance Test

| Temperature | Exposure Time | Weight Gain |

|---|---|---|

| 705°C | 100 hours | 0.2 g/m² |

| 815°C | 100 hours | 1.7 g/m² |

| 980°C | 100 hours | 340 g/m² |

| 1090°C | 100 hours | 10,000 g/m²* |

* Indicates significant oxidation – not recommended for continuous use at this temperature

Performance You Can Trust

- Creep resistance: Excellent at temperatures up to 800°C

- Fatigue strength: Maintains 80% of room temp strength at 600°C

- Corrosion resistance: Superior in oxidizing environments

- Thermal expansion: 16.0 × 10⁻⁶/°C (20-1000°C)

- Thermal conductivity: 16.2 W/m·K at 100°C

Key Features – Why Our Parts Are Better

Extreme Heat Resistance

Withstands up to 1100°C – hotter than most industrial furnaces

Corrosion Resistant

Protective oxide layer prevents rust even at high temperatures

High Strength

Maintains structural integrity even under extreme thermal stress

Precision Machined

Tight tolerances ensure perfect fit in your high-temperature systems

Long Lasting

Durable construction means less downtime and replacement costs

Environmentally Friendly

100% recyclable material with minimal environmental impact

Applications – We Do It All

Aerospace

Jet engines, exhaust systems, heat shields

Industrial Furnaces

Heating elements, conveyor systems, burners

Automotive

Exhaust manifolds, turbochargers, catalytic converters

Chemical Processing

Reactors, pipes, valves, pumps

Laboratory Equipment

High-temperature ovens, autoclaves, crucibles

Power Generation

Boilers, turbines, heat exchangers

Why Choose Us? – Let Us Count The Ways

26 Years of High-Temperature Expertise

Bro, we’ve been making parts for extreme environments since 1999! That’s not just experience – that’s mastery.

We’ve seen it all, solved it all, and we keep getting better.

Customization Experts

Need a specific shape, size, or alloy? We can make it happen. No design is too complex for us.

Our team works with you to create exactly what you need – no compromises.

Quality Guaranteed

Every product undergoes strict quality control. We don’t ship anything we wouldn’t use ourselves.

If you’re not happy, we’re not happy – it’s that simple.

Ready to take your high-temperature systems to the next level?

Let’s Create Something Amazing

We’re here to help you with all your high-temperature stainless steel needs

Phone

+86-18150097490

charlie@plasticmetalparts.com

Location

Xiamen, China