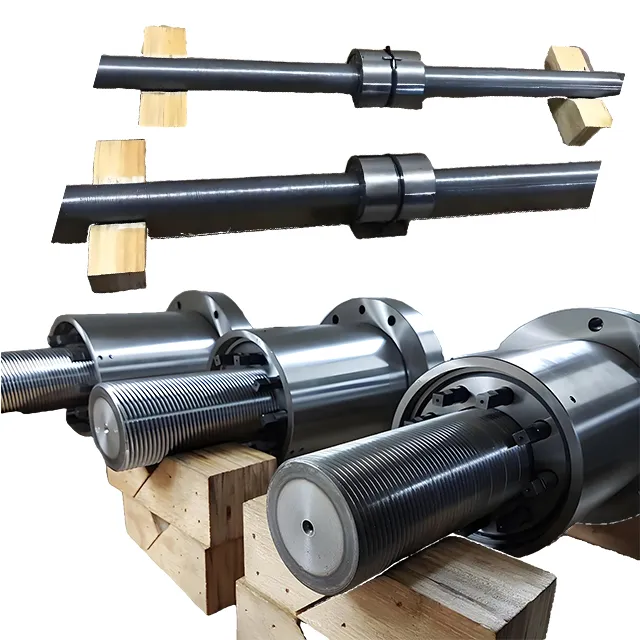

Customized machine tool fixtures for high precision brass planetary roller screw turning and milling products

Place of Origin:Fujian, China

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Micro Machining or Not:Micro Machining

Model Number:CMP-65

Brand Name:JSD

Product name:planetary roller screw

Service:Customized OEM

Material:Stainless Steel

Process:Cnc Machining+deburrs

Application:Industrial Equipment

Surface treatment:Plating

Keyword:CNC Macining Parts

Equipment:CNC Machining Centres

Name:Customized Machined CNC Machining

Item:CNC Precision Machining Part

Description

Product Introduction

This customized machine tool fixture high-precision brass planetary roller screw turning and milling product is carefully crafted to meet the needs of high-precision machining. The planetary roller screw made of brass has unique advantages in the field of machine tool fixtures. Its good thermal conductivity helps to dissipate heat during the processing process and reduce the precision error caused by thermal deformation.

Material characteristics

High-quality brass is selected as the raw material. Brass has moderate hardness and toughness, which can not only ensure smooth forming during the turning and milling process, but also withstand certain processing stress without cracking or deformation. Its excellent wear resistance makes the surface of the processed planetary roller screw smooth and the friction coefficient low, which is conducive to improving the transmission efficiency and service life of the screw. In addition, the corrosion resistance of brass can also resist the erosion of factors such as moisture and chemicals in the processing environment to a certain extent, ensuring the long-term stability of the product.

Processing accuracy

Through advanced turning and milling technology and high-precision processing equipment, we can achieve ultra-precision processing of brass planetary roller screws. From the pitch accuracy of the screw to the cylindricity, surface roughness and other indicators, they are strictly controlled within a very small tolerance range. For example, the pitch accuracy can reach within ±0.005mm, the cylindrical deviation does not exceed 0.003mm, and the surface roughness Ra value can be as low as 0.8μm. This high-precision processing result can meet the strict requirements of high-end machine tool fixtures for planetary roller screws, ensure the positioning accuracy and repeat positioning accuracy of the machine tool during operation, and thus improve the quality and consistency of the processed workpiece.

Customization Advantages

We are well aware that different machine tool fixture application scenarios have different requirements for planetary roller screws. Therefore, we provide a full range of customized services, whether it is the length, diameter, thread specifications of the screw, or the special end structure design, which can be tailored according to the specific requirements of the customer. The professional technical team will communicate closely with customers, from the formulation of the design plan to the monitoring of the processing process, and then to the quality inspection of the final product, to ensure that each customized brass planetary roller screw can perfectly fit the customer’s machine tool fixture system, provide customers with unique solutions, and help them stand out in the fierce market competition.

Quality inspection and after-sales guarantee

During the production process, a strict multi-stage quality inspection system is implemented. Raw material inspection ensures that the quality of brass materials meets the standards, random inspections during processing promptly discover and correct possible deviations, and finished product inspections conduct comprehensive tests on various performance indicators of planetary roller screws. At the same time, we provide comprehensive after-sales guarantee services. If customers find any quality problems during use, we will respond quickly and provide solutions such as repairs and replacements. With customer satisfaction as the primary goal, customers can choose our customized products without worries.